Nickel-cobalt-iron ternary oxide water electrolysis composite material, preparation method and application thereof

A technology of ternary oxides and composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrolytic components, etc., can solve problems such as difficult control of morphology and electronic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

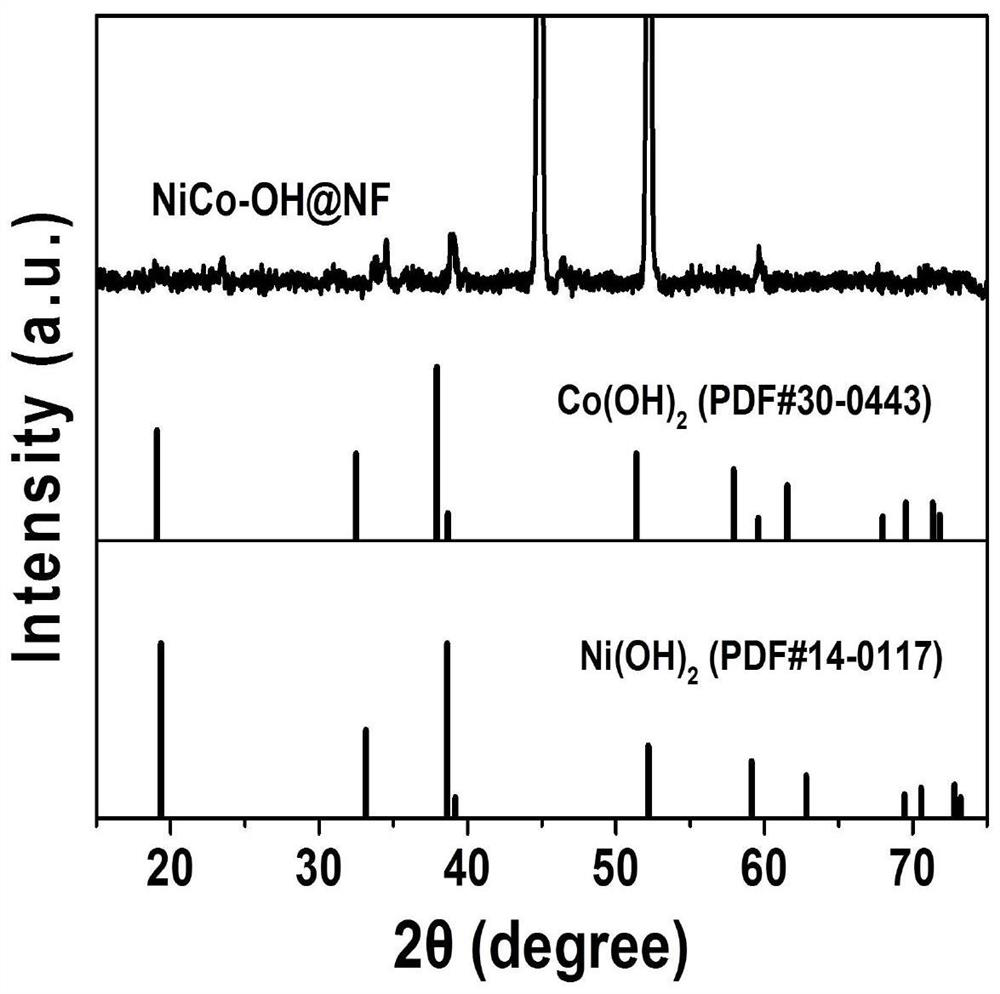

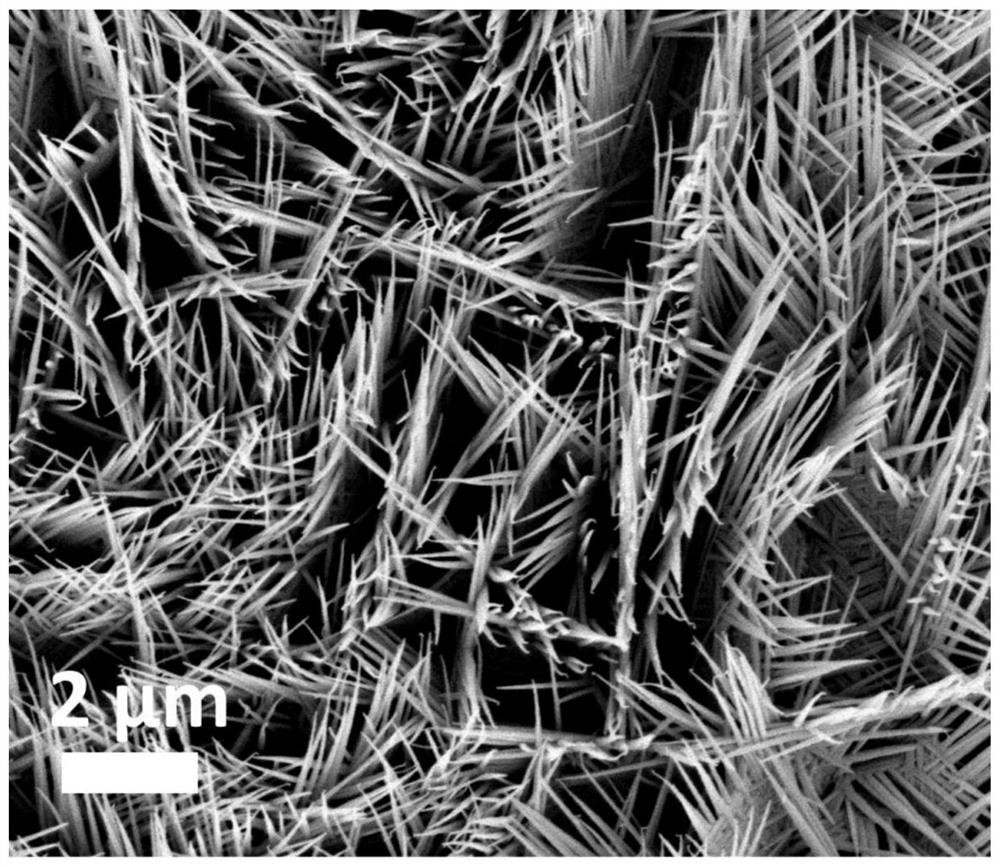

[0042] (1) The preparation method of the nickel-cobalt composite hydroxide precursor is as follows: the nickel foam is ultrasonically cleaned with a mixed solution of acetone and hydrochloric acid for 20-30 minutes to remove the grease and oxide layer on the surface of the nickel foam. 0.291 g of cobalt nitrate hexahydrate, 0.29 g of nickel nitrate hexahydrate, 0.6 g of urea and 0.186 g of ammonium fluoride were dissolved in 30 ml of deionized water and stirred for 30 minutes to obtain solution A. Transfer the solution A to the reaction kettle, put the pre-treated nickel foam into the solution, put it in an oven, and react at 120 degrees Celsius for 6 hours. Wash with absolute ethanol for 3 to 4 times, put it in a vacuum oven and bake at 60 degrees Celsius for 12 hours to obtain the precursor of nickel-cobalt hydroxide, which is recorded as NiCo-OH@NF.

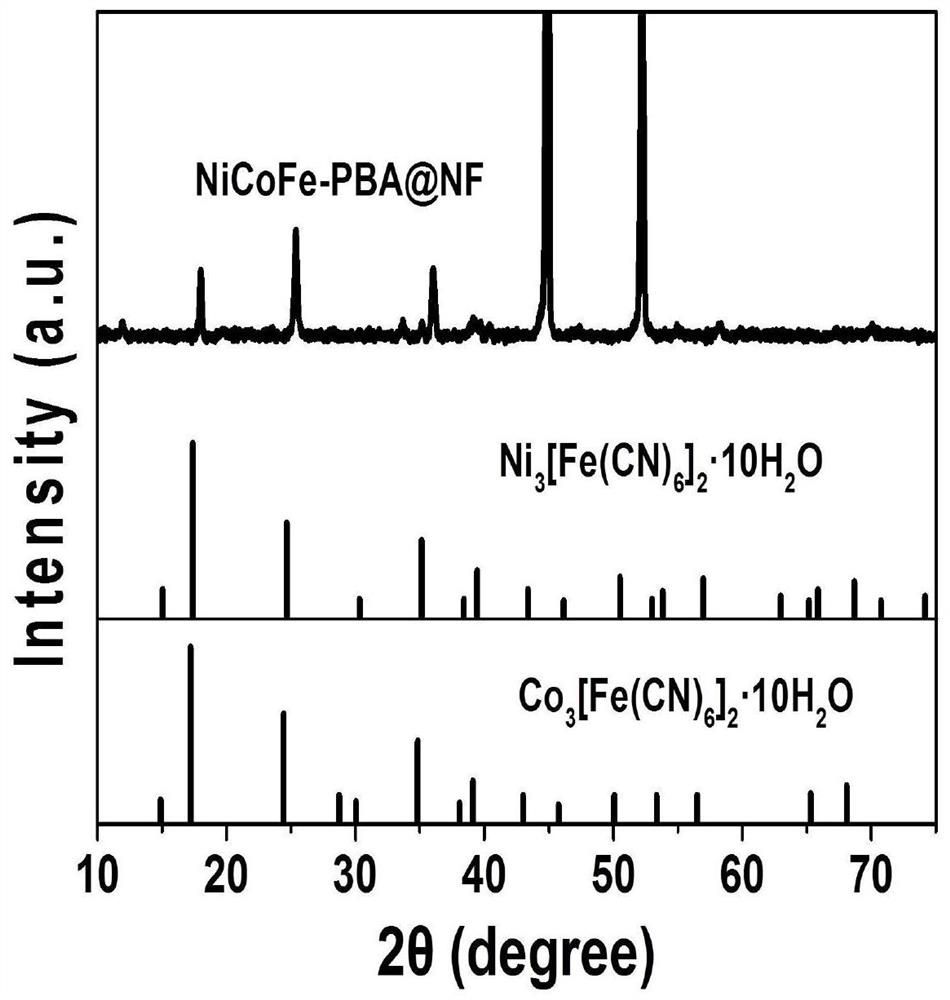

[0043](2) The preparation method of the nickel-cobalt-iron Prussian blue analogue precursor is as follows: 0.33 g of potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com