Aromatic nursing agent for textile fabric

A technology of textile fabrics and care agents, applied in the field of textile fabrics, to achieve the effect of increasing the fragrance retention effect, fresh and elegant fragrance, and long-lasting release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

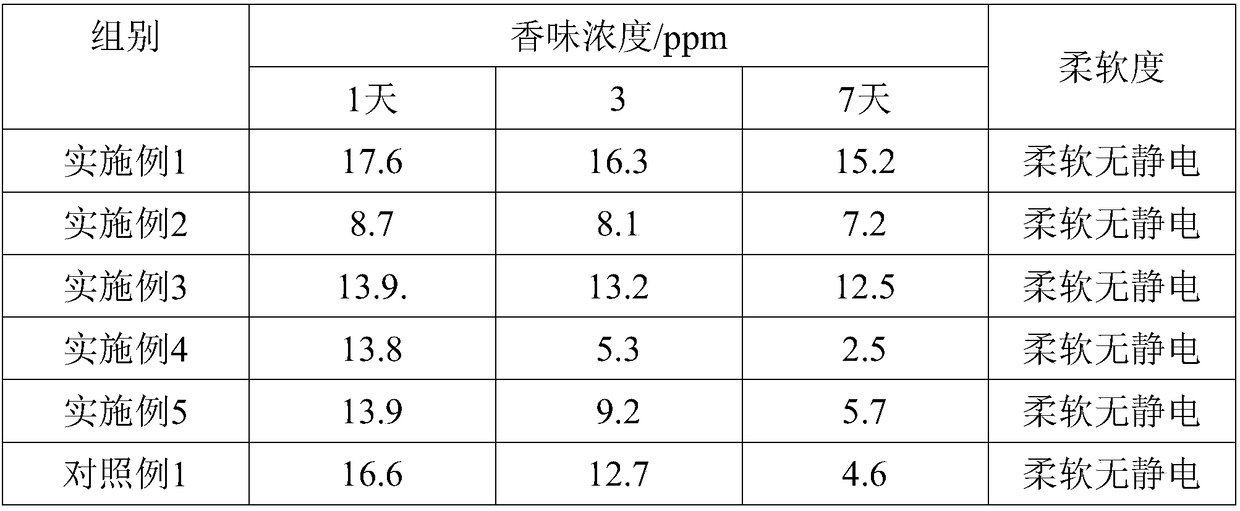

Examples

Embodiment 1

[0021] An aromatic care agent for textile fabrics, which is made from the following raw materials by weight: 20 parts of isopropyl alcohol, 15 parts of ethylene glycol, 10 parts of essence, 10 parts of activated carbon, 15 parts of alcohol, and 4 parts of nano-silicon dioxide. parts, 5 parts of silicone oil, 2 parts of glycerin, 2 parts of chitosan, 0.8 parts of silver ions, and 100 parts of deionized water.

[0022] The preparation method of the described aromatic care agent for textile fabrics comprises the following steps:

[0023] (1) Grind the activated carbon to a size of 60-80um, drop the essence and alcohol, and treat it with a microwave with a frequency of 2450MHz and a power of 700W for 15-20min;

[0024] (2) adding the mixture of step 1 to nano-silica, and stirring with a mixer of 800-1000r / min for 20-25 minutes to obtain substance I;

[0025] (3) Mix isopropanol, ethylene glycol, silicone oil, and deionized water, heat to a molten state, add chitosan, stir evenly,...

Embodiment 2

[0028] An aromatic care agent for textile fabrics, which is made from the following raw materials by weight: 30 parts of isopropyl alcohol, 20 parts of ethylene glycol, 20 parts of aromatic essential oils, 20 parts of activated carbon, 25 parts of alcohol, and nano-silica 8 parts, 10 parts of silicone oil, 5 parts of glycerin, 8 parts of chitosan, 2 parts of silver ions, 120 parts of deionized water.

[0029] The aromatic essential oil is made from the following raw materials in parts by weight: 80 parts of rose, 40 parts of magnolia, 20 parts of frankincense, 10 parts of Cyperus officinalis, 8 parts of Atractylodes, 8 parts of ginger, 10 parts of grapefruit peel, 10 parts of lemon peel, eucalyptus 6 servings of leaves.

[0030] The preparation method of the aromatic essential oil includes the following steps: mixing rose, magnolia, frankincense, Cyperus officinalis, herb, ginger, grapefruit peel, lemon peel, and eucalyptus leaves, adding 3 times by weight of anhydrous alcohol...

Embodiment 3

[0037] An aromatic care agent for textile fabrics, which is made from the following raw materials by weight: 25 parts of isopropyl alcohol, 18 parts of ethylene glycol, 15 parts of aromatic essential oils, 15 parts of activated carbon, 20 parts of alcohol, and nano-silica 6 parts, 8 parts of silicone oil, 4 parts of glycerin, 6 parts of chitosan, 1.5 parts of silver ions, 110 parts of deionized water.

[0038] The aromatic essential oil is made from the following raw materials in parts by weight: 65 parts of rose, 30 parts of magnolia, 18 parts of frankincense, 8 parts of Cyperus officinalis, 5 parts of atractylodes, 6 parts of ginger, 8 parts of grapefruit peel, 8 parts of lemon peel, eucalyptus 5 servings of leaves.

[0039] The preparation method of the aromatic essential oil includes the following steps: mixing rose, magnolia, frankincense, Cyperus officinalis, atractylodes, ginger, grapefruit peel, lemon peel, and eucalyptus leaves, and adding 2 times the weight fraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com