Composite electrolytic paper and preparation method thereof

A technology of electrolytic paper and composite nanofibers, which is applied in the direction of papermaking, paper, special paper, etc., can solve the problems of poor consistency, large core package volume, and reduced pressure resistance, and achieve improved mechanical properties, shortened current paths, and loss Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation device and preparation method of the composite electrolytic paper of the present invention will be described in detail below.

[0070] 1. Preparation device of composite electrolytic paper

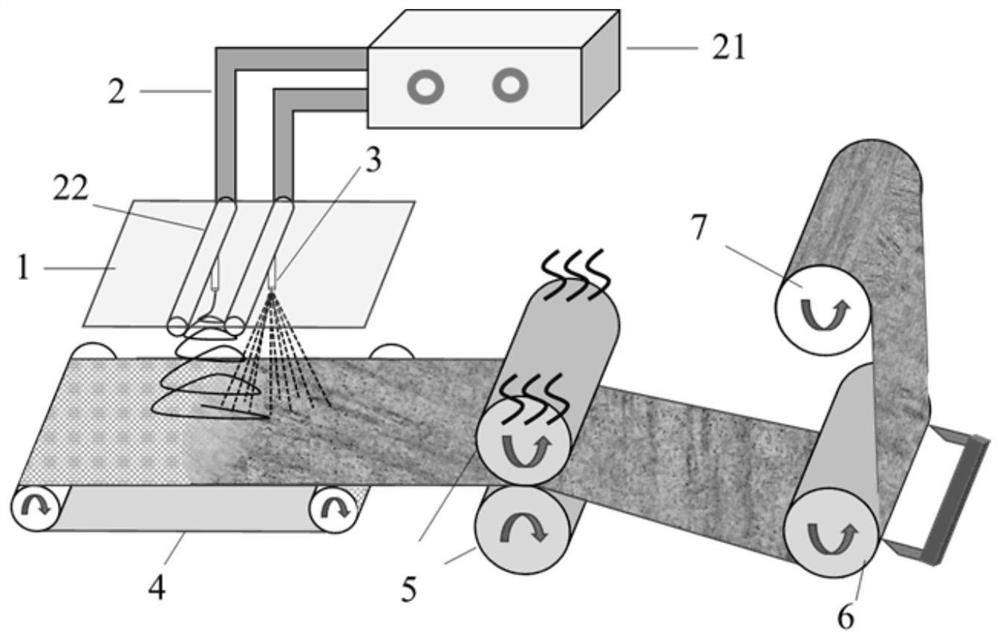

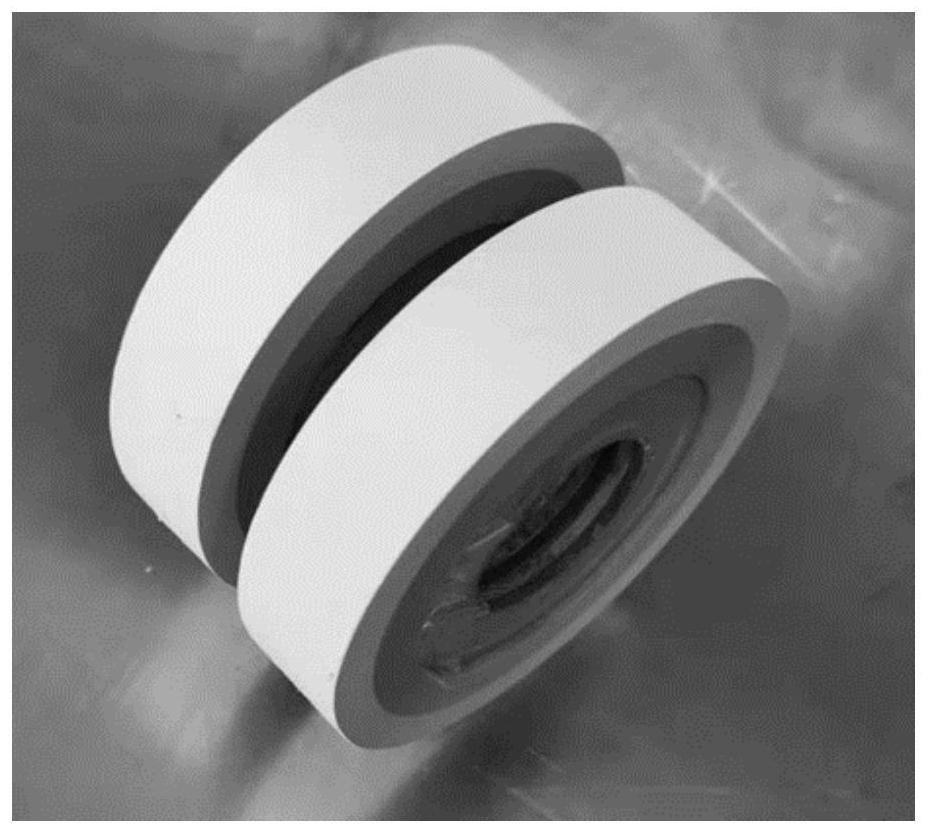

[0071] like figure 1 As shown, the preparation device for composite electrolytic paper provided by the present invention includes: a positive and high voltage electrode plate 1, a liquid supply device 2, a spinneret 3, a crawler belt 4, a hot pressing roller 5, a cutting roller 6 and a winding roller 7 ;

[0072] in:

[0073] A high-voltage electrostatic field is formed between the positive and high-voltage electrode plate 1 and the crawler belt 4, so as to ensure the continuous process of electrospinning and electrostatic spraying;

[0074] In some embodiments, the liquid supply device 2 is located below the positive and high voltage electrode plate, and the liquid supply device 2 includes a syringe pump 21 and a liquid supply pipe 22. One liquid supply pipe is u...

Embodiment 1

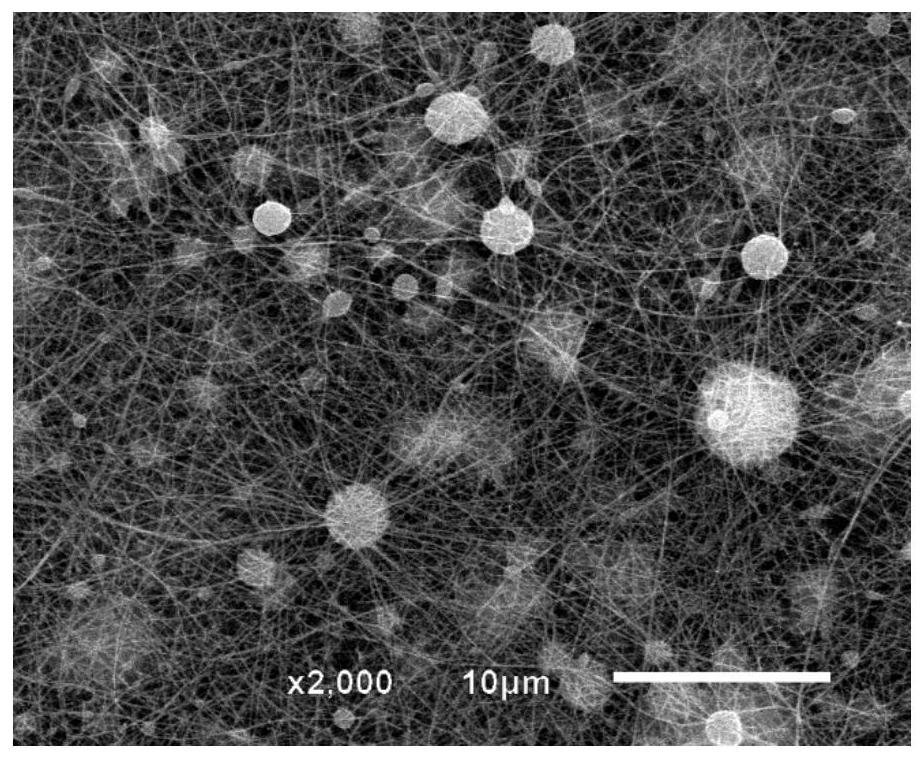

[0117] Taking the preparation process of polyimide nanofiber / polyvinylidene fluoride particle composite electrolytic paper as an example, it mainly includes the following steps:

[0118] The first step, preparation of electrospinning solution: dissolve 4,4'-aminodiphenyl ether and pyromellitic anhydride with a molar ratio of 1:1 in a certain amount of N,N-dimethylformamide respectively , in which the mass proportion of the solute is 15%, and a clarified electrospinning solution is obtained by fully stirring at 25 °C;

[0119] The second step, the preparation of electrostatic spray liquid: add a certain amount of polyvinylidene fluoride powder to a certain amount of N,N-dimethylformamide, in which the solute mass accounts for 3%, and fully stir at 60 ° C to obtain clarification Electrostatic spray liquid;

[0120] The third step, use figure 1 In the preparation device shown, the electrospinning solution and the electrostatic spraying solution are respectively introduced into ...

Embodiment 2

[0125] In this example, the difference from Example 1 is that the mass fraction of the solute in the electrospinning solution is adjusted to 20%, and other parameters remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com