Preparation of an inorganic-organic composite gel membrane and its application in the separation of hydrocarbon mixtures

A technology of hydrocarbon mixtures and composite gels, applied in semipermeable membrane separation, inorganic chemistry, alkali metal compounds, etc., can solve problems such as insufficient stability, low separation efficiency, and poor mechanical properties, and achieve enhanced adsorption selectivity, Good adsorption performance, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

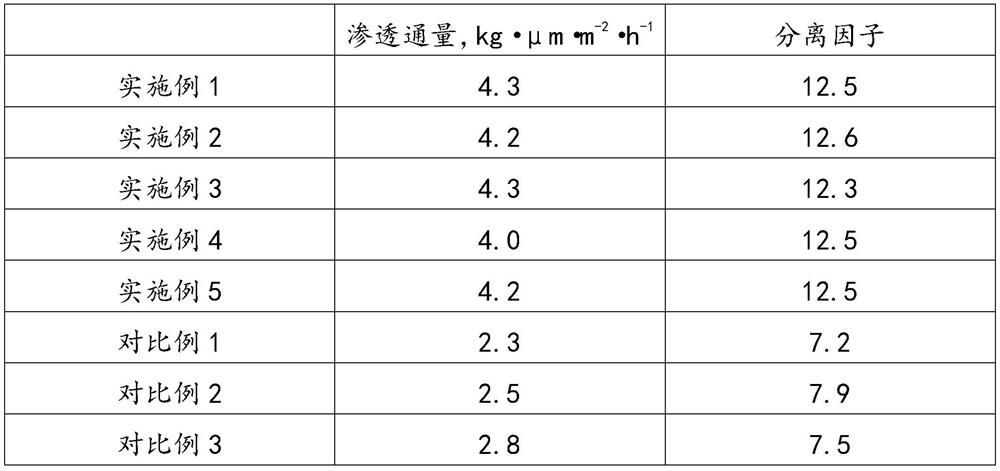

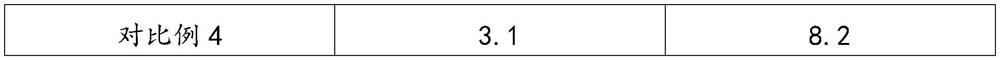

Examples

Embodiment 1

[0028] (1) Mix 0.3g of 5-aminoisophthalic acid, 1g of cobalt nitrate hexahydrate, 50ml of DMF, and 50ml of deionized water. After ultrasonic mixing at 500W power, put them in the reactor, and react at 95°C for 40h, and the reaction is over. After making mixed solution A;

[0029](2) Put 0.2g graphene nanosheets in 50ml6mol / L concentrated nitric acid for 30min, then disperse in 50ml deionized water, then add 500ml 30g / L cobalt nitrate hexahydrate solution, and add 15g urea, ultrasonic at 500W power After mixing, stir and react at 80°C for 1 hour. After the reaction, the solid obtained after centrifugation of the reaction liquid was redispersed in 100ml of deionized water, and then 20g of acrylamide, 0.001g of N,N-methylenebisacrylamide and 0.001 g potassium persulfate, polymerized at 60°C for 2 hours to prepare mixed liquid B;

[0030] (3) Soak the PAN membrane in 100ml of 30% ethanol aqueous solution for 2h, then take it out and rinse it with deionized water for 2-3 times, th...

Embodiment 2

[0032] (1) Mix 0.7g of 5-aminoisophthalic acid, 2g of cobalt nitrate hexahydrate, 50ml of DMF, and 50ml of deionized water. After ultrasonic mixing at 500W power, place it in a reactor, and react at 105°C for 50h, and the reaction ends After making mixed solution A;

[0033] (2) Put 0.6g graphene nanosheets in 50ml6mol / L concentrated nitric acid for 30min, then disperse in 50ml deionized water, then add 500ml 30g / L cobalt nitrate hexahydrate solution, and add 20g urea, ultrasonic at 500W power After mixing, stir and react at 100°C for 4 hours. After the reaction, the solid obtained after the centrifugation of the reaction solution was redispersed in 100ml of deionized water, and then 30g of acrylamide, 0.002g of N,N-methylenebisacrylamide and 0.002 g potassium persulfate, polymerized at 90°C for 6 hours to prepare mixed liquid B;

[0034] (3) Soak the PAN membrane in 100ml of 40% ethanol aqueous solution for 3 hours, then take it out and rinse it with deionized water for 3 ti...

Embodiment 3

[0036] (1) Mix 0.4g of 5-aminoisophthalic acid, 1.5g of cobalt nitrate hexahydrate, 50ml of DMF, and 50ml of deionized water, mix them ultrasonically under 500W power, place them in a reactor, and carry out the reaction at 100°C for 42 hours. Mixed solution A is obtained after finishing;

[0037] (2) Put 0.3g graphene nanosheets in 50ml6mol / L concentrated nitric acid for 30min, then disperse in 50ml deionized water, then add 500ml 30g / L cobalt nitrate hexahydrate solution, and add 16g urea, ultrasonic at 500W power After mixing, the reaction was stirred at 85°C for 2 hours. After the reaction, the solid obtained after centrifugation of the reaction solution was redispersed in 100ml of deionized water, and then 22g of acrylamide, 0.001g of N,N-methylenebisacrylamide and 0.001 g potassium persulfate, polymerized at 70°C for 3 hours to prepare mixed liquid B;

[0038] (3) Soak the PAN membrane in 100ml of 30% ethanol aqueous solution for 2h, then take it out and rinse it with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com