Nursing agent for textile fabric

A technology of textile fabrics and care agents, applied in the field of textile fabrics, to achieve the effect of long-lasting, fresh and elegant fragrance, and long-lasting release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

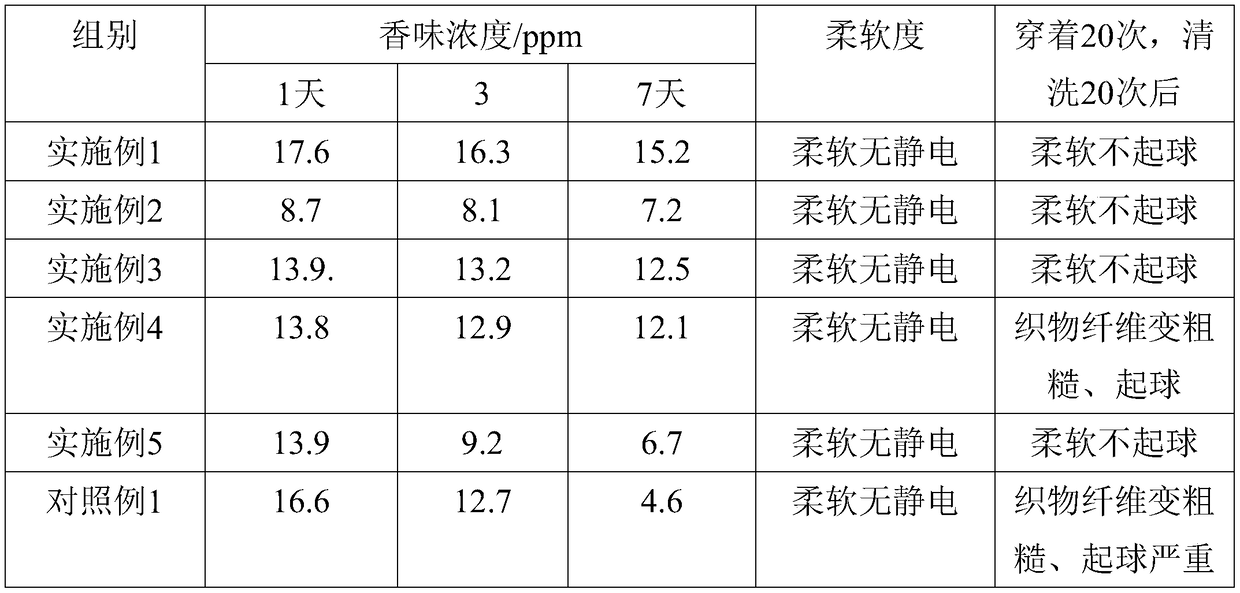

Examples

Embodiment 1

[0024] A care agent for textile fabrics, made of the following raw materials in parts by weight: 20 parts of modified nano-powder glue, 15 parts of ethylene glycol, 10 parts of essence, 10 parts of activated carbon, 15 parts of alcohol, carboxymethyl fiber 4 parts of vegetable, 5 parts of natural coconut oil, 2 parts of glycerin, 2 parts of sorbitol, 0.8 parts of silver ion, 100 parts of deionized water.

[0025] The modified nano-powder glue is made of nano-silica, chitosan, silicone oil and isopropanol. The specific preparation method is: add absolute ethanol dropwise to the nano-silica under stirring until completely dissolved, and simultaneously add Add deionized water dropwise to the chitosan until it is completely dissolved, then add the ethanol solution of nano silicon dioxide, silicone oil and 95wt% concentrated sulfuric acid to the chitosan solution, stir and mix with a stirrer, the stirring speed is 600-800r / min , the stirring time is 5-10 minutes, after the stirring...

Embodiment 2

[0033] A care agent for textile fabrics, made of the following raw materials in parts by weight: 30 parts of modified nano-powder glue, 20 parts of ethylene glycol, 20 parts of aromatic essential oils, 20 parts of activated carbon, 25 parts of alcohol, carboxymethyl 8 parts of cellulose, 10 parts of natural coconut oil, 5 parts of glycerin, 8 parts of sorbitol, 2 parts of silver ion, 120 parts of deionized water.

[0034] The modified nano-powder glue is made of nano-silica, chitosan, silicone oil and isopropanol. The specific preparation method is: add absolute ethanol dropwise to the nano-silica under stirring until completely dissolved, and simultaneously add Add deionized water dropwise to the chitosan until it is completely dissolved, then add the ethanol solution of nano silicon dioxide, silicone oil and 95wt% concentrated sulfuric acid to the chitosan solution, stir and mix with a stirrer, the stirring speed is 600-800r / min , the stirring time is 5-10 minutes, after the...

Embodiment 3

[0044] A care agent for textile fabrics, made of the following raw materials in parts by weight: 25 parts of modified nano-powder glue, 18 parts of ethylene glycol, 15 parts of aromatic essential oil, 15 parts of activated carbon, 20 parts of alcohol, carboxymethyl 6 parts of cellulose, 8 parts of natural coconut oil, 4 parts of glycerin, 6 parts of sorbitol, 1.5 parts of silver ion, 110 parts of deionized water.

[0045] The modified nano-powder glue is made of nano-silica, chitosan, silicone oil and isopropanol. The specific preparation method is: add absolute ethanol dropwise to the nano-silica under stirring until completely dissolved, and simultaneously add Add deionized water dropwise in the chitosan until it is completely dissolved, then add the ethanol solution of nano silicon dioxide, silicone oil and 95wt% concentrated sulfuric acid to the chitosan solution, stir and mix with a stirrer, the stirring speed is 700r / min, stir The time is 10 minutes. After the stirring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com