Hopper device for spring-free microcomputer combined scale

A combined scale, springless technology, applied to measuring devices, instruments, weighing, etc., can solve problems such as difficult to clean, reduce accuracy, make noise, etc., achieve the effect of convenient cleaning and maintenance, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

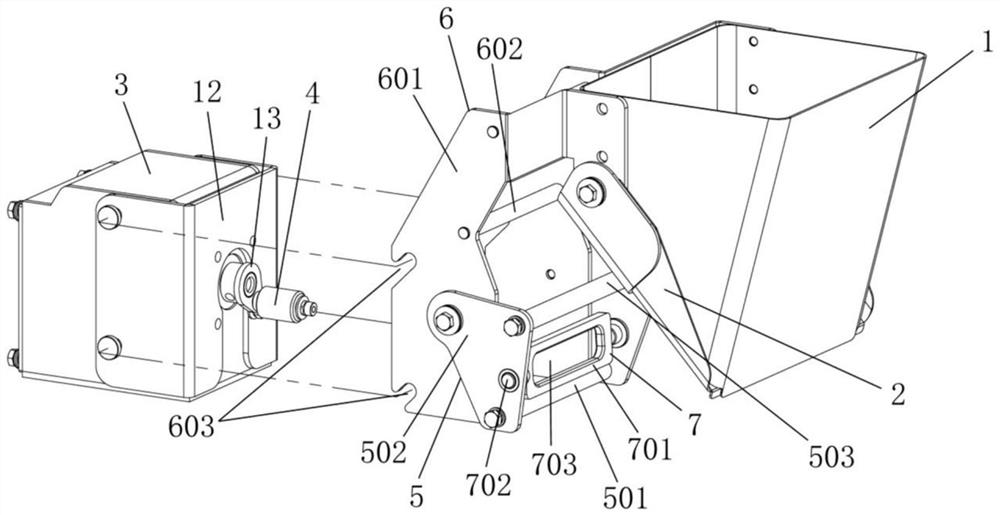

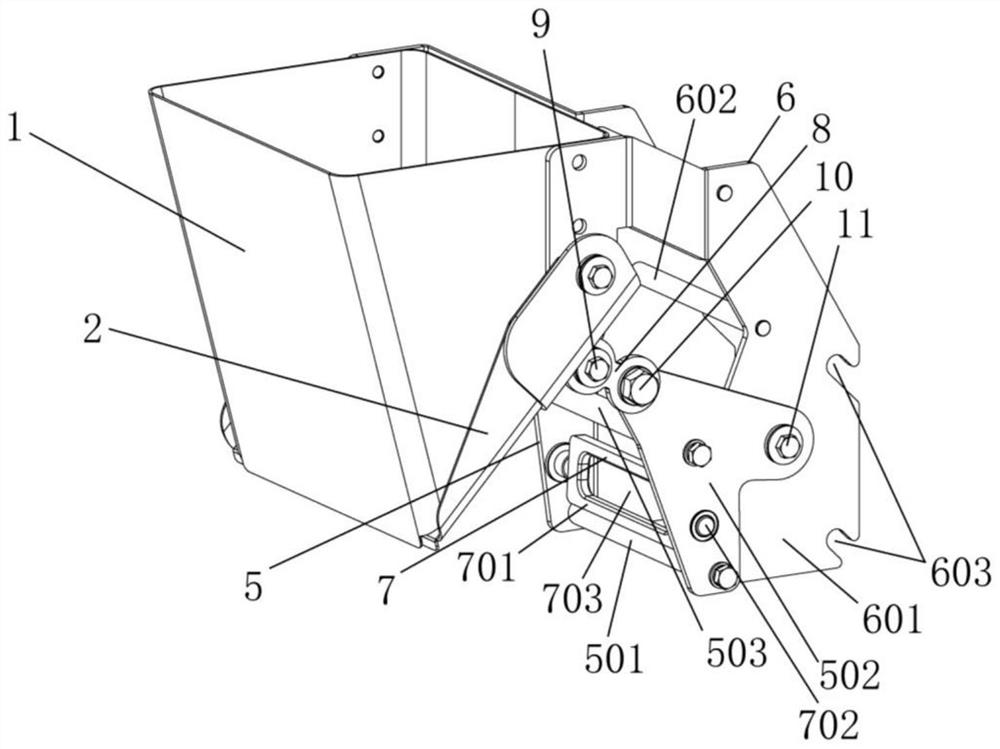

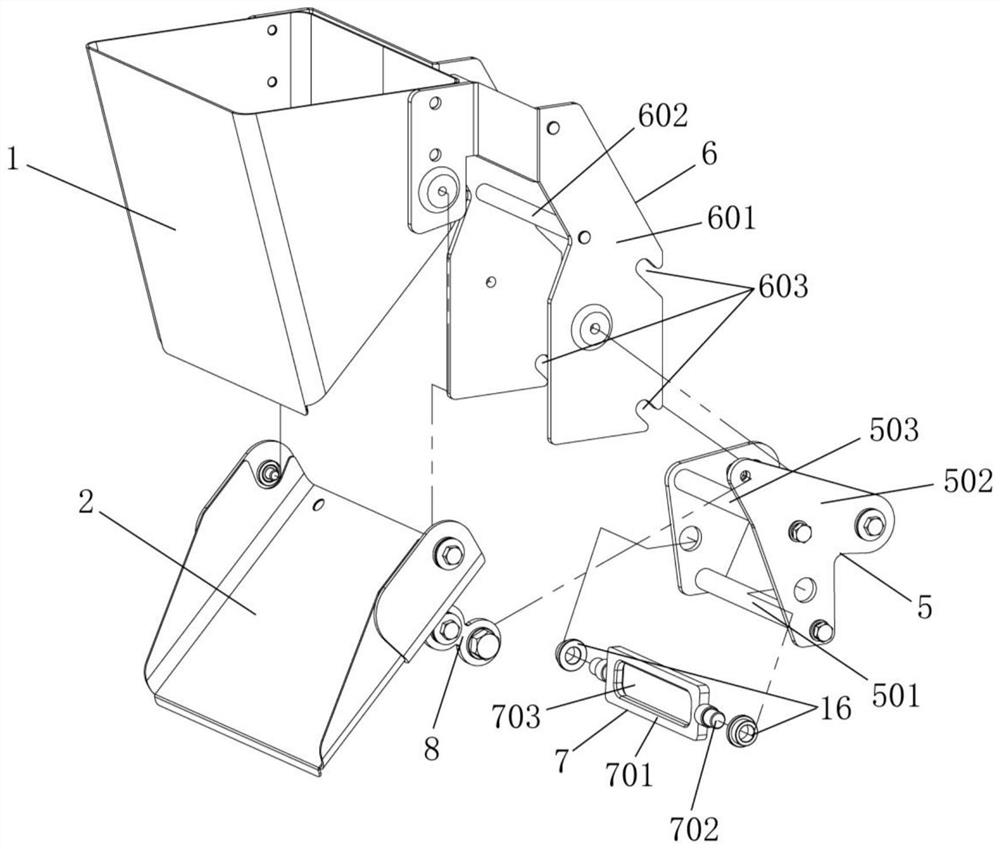

[0028] Such as Figures 1 to 3 As shown, a hopper device for a springless microcomputer combination scale includes a hopper body 1, a hopper door 2, a motor 3, a swing rod 4, a movable bracket 5, and a mounting frame 6, and the swing rod 4 is connected to the motor 3 The output end of the motor 3 is mounted on the mounting frame 6, the movable bracket 5 is connected to the mounting frame 6, the hopper body 1 is mounted on the mounting frame 6, and the hopper door 2 is connected to the mounting frame 6. The hopper body 1 is connected, and it is characterized in that it also includes a door drive shaft 7 and a pull rod 8, the hopper door 2 is connected with the movable bracket 5 through a pull rod 8, and the bucket door drive shaft 7 is installed on the movable bracket 5 , the swing link 4 is movably connected with the bucket door drive shaft 7 . The bucket door driving shaft 7 includes a driving frame 701 and a rotating shaft 702 fixed at both ends of the driving frame 701. A ...

Embodiment 2

[0038] This springless microcomputer combined scale hopper device is the same as the embodiment except the following technical features. The self-locking part is a baffle, the baffle is located at the lower end of the first side plate, and the baffle and the first side plate are perpendicular to each other. That is, the self-locking rod in Embodiment 1 is replaced with a baffle plate, and other structures remain unchanged. The baffle plate and the first side plate 502 are perpendicular to each other and integrally formed with the first side plate 502 to simplify production and installation steps. Simultaneously, the structure of the device is simpler. When the motor control pendulum 4 moves to the bottom, the hopper door 2 is closed, and now the baffle plate withstands the mounting bracket 6, realizing the self-locking with the same effect as in embodiment 1, ensuring that the hopper door is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com