Piezoelectric-driven vacuum sealing micro-mirror

A sealed micromirror, piezoelectric drive technology, applied in the field of three-dimensional imaging, can solve the problems of the galvanometer module being unable to continue to be used, the large-scale application of the galvanometer, affecting the experience of equipment use, etc., achieving low manufacturing cost, small size, The effect of power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

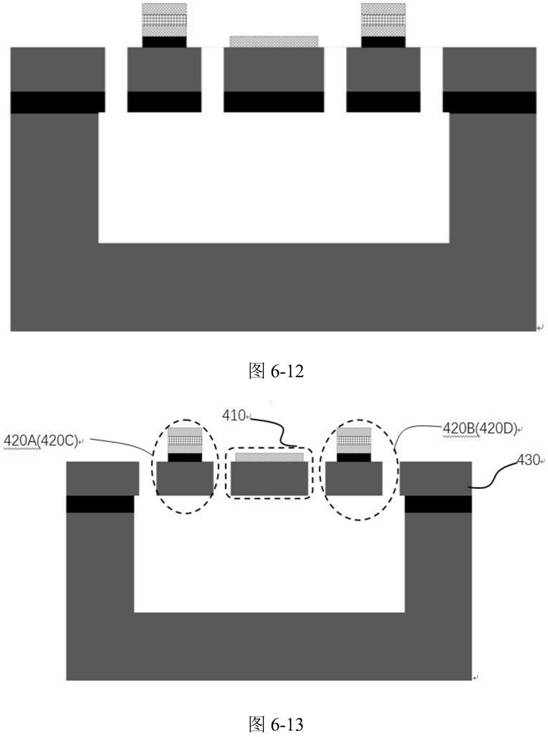

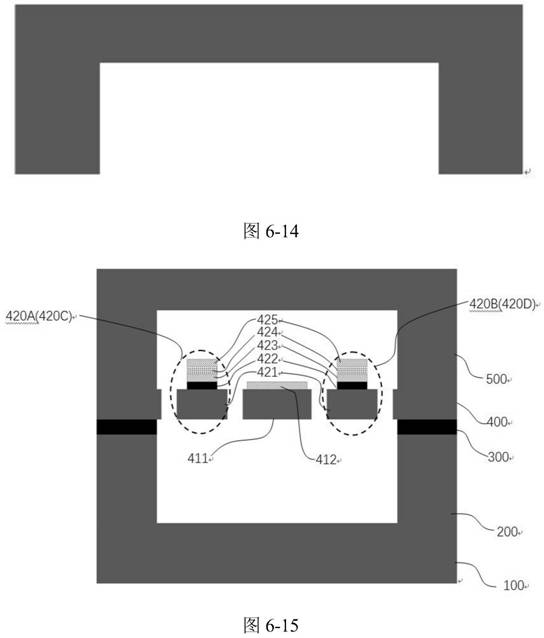

[0045] Such as figure 1 , the structural layer is a vacuum-sealed micromirror driven by uniaxial piezoelectricity, which is composed of a substrate 100 , a back cavity plate 200 , an isolation layer 300 , a structural layer 400 and a front cavity plate 500 from bottom to top. There is a vacuum cavity 800 inside the micromirror, and the movable part in the structure layer 400 is located in the vacuum cavity 800; the vibration of the movable part all occurs in a vacuum environment, and the noise of the interaction between the structure and the air is not generated. The weak vibration of the micromirror cannot be transmitted to the outside of the micromirror due to the vacuum environment.

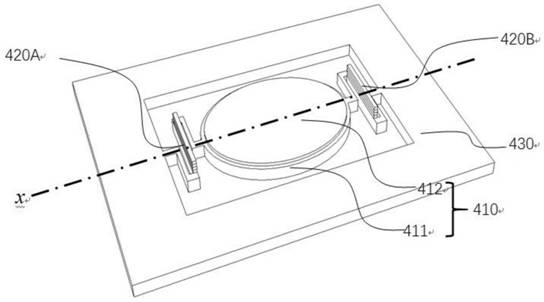

[0046] Such as figure 2, the uniaxial structure layer 400 has a mirror 410, and the mirror 410 is composed of a mirror body 411 and a mirror surface 412 covering the upper surface thereof. Both sides of the mirror body 411 are respectively connected to the outer frame 430 through the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com