Rapid sewing device for doll production

A suture device and doll technology, applied in entertainment, toys, etc., can solve the problems of inconvenient operation and low efficiency of manual sealing, and achieve the effect of improving suture efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

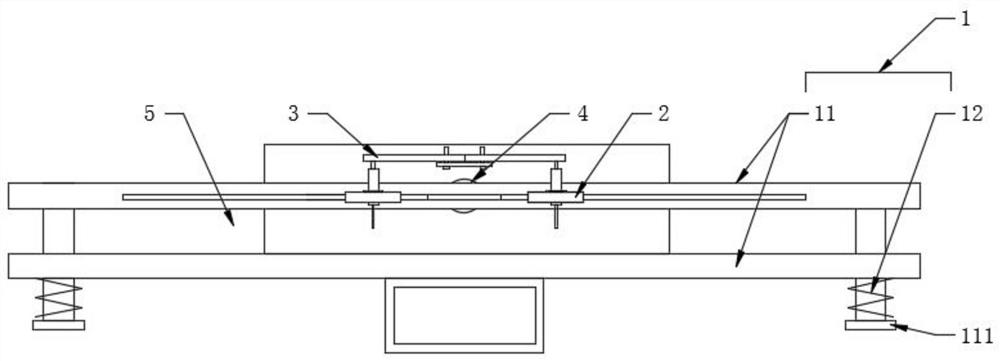

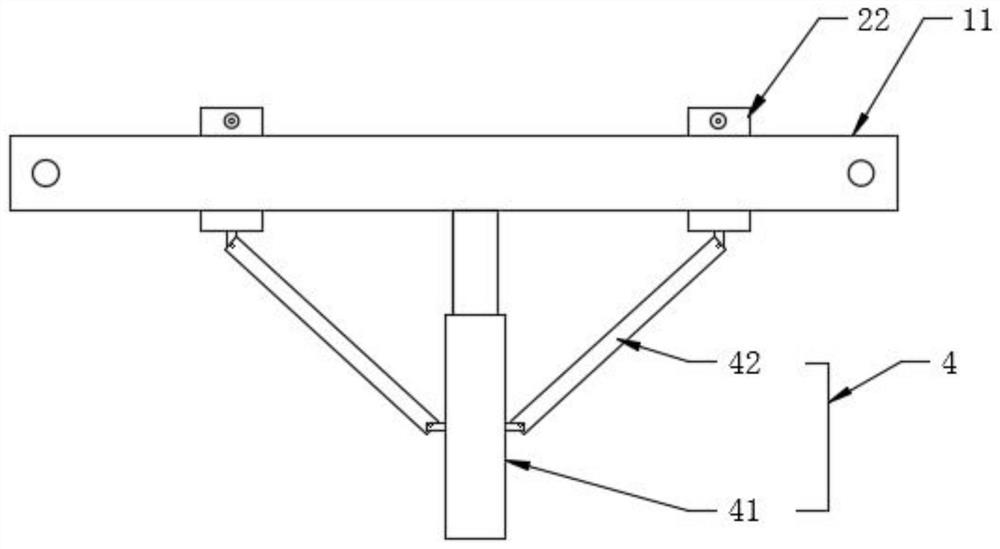

[0035] see Figure 1-5 , a quick suture device for the production of dolls. This suture device needs to be used in conjunction with an external suture machine, including a jaw device 1, a nail insertion device 2, a linkage device 3 and a driving device 4. The jaw device 1 includes two parallel distributed Clamping plate 11 and spring 12, two clamping plates 11 are elastically matched by spring 12, and the gap between two clamping plates 11 is clamping area 5, and clamping area 5 is used for placing the reserved sealing area that needs cloth doll to sew, further Description, one side of one splint 11 is welded with a T-shaped sliding shaft 111 that runs through the other splint 11, and the spring 12 is sleeved on the T-shaped sliding shaft 111 and located outside the two splints 11. Normally, the spring 12 Under the action of the two splints 11 oppositely clamped, a traction device or a manual handle can be set on one side of one of the splints 11 to control the opening of the ...

Embodiment 2

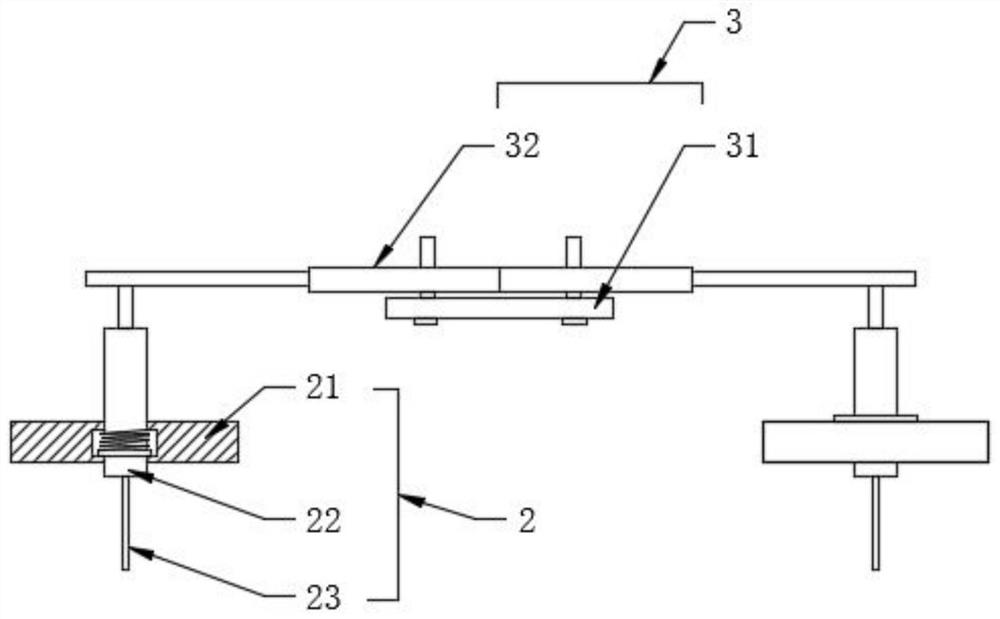

[0037] see figure 2 , the difference from Embodiment 1 is that the linkage device 3 includes a shifting plate 31 and two connecting plates 32 that are located on the same side of the shifting plate 31 as facing or reverse sliding fit, and one side of the shifting plate 31 can be welded vertically with two guides. The column 22, the two connecting plates 32 and the guide column 22 run through sliding fit. The connecting plate 32 is a telescopic structure. The telescopic structure adopts a common sleeve and rod structure. It is fixedly connected, and thus, a connecting plate 32 is moved outwards to realize the docking of a single pin 23 and one end of the reserved seal of the doll, which is convenient for plugging in with the reserved seal, and after the sewing is completed, the dial is moved outwards The plate 31 can realize that the two pins 23 are separated from the doll as a whole.

Embodiment 3

[0039] see Figure 5, the difference from Example 1 is that the opposite sides of the two splints 11 are bonded with rubber pads 6, and the outer wall of the rubber pads 6 is jagged. Since the doll is a plush toy, the friction force directly contacting the splint 11 Small, when the two splints 11 are directly clamped to the reserved area of the seal, when the external sewing and sealing machine sews, a pulling force will be generated, and the reserved seal of the doll is easily deformed. By setting the rubber pad 6, this problem can be solved. The bottom of another clamping plate 11 is fixedly provided with the suspension bar 113 of vertical distribution, and one side of suspension bar 113 is fixedly provided with supporting plate 1131, and supporting plate 1131 has the effect of lifting doll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com