A Soft Electrostatic Adhesive Coated Bionic Octopus Manipulator

An electrostatic adhesion and coating technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of large differences in electrostatic adhesion effects, unstable clamping performance, and insufficient clamping force, etc., to reduce the impact Risk of damage, simple structure, effect of increasing clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

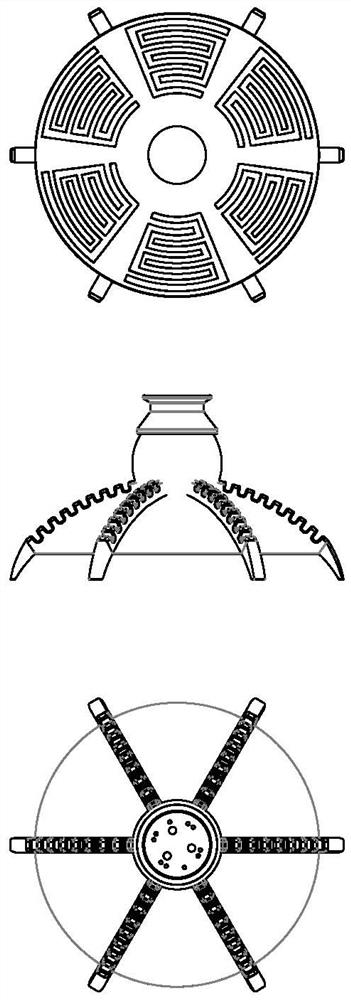

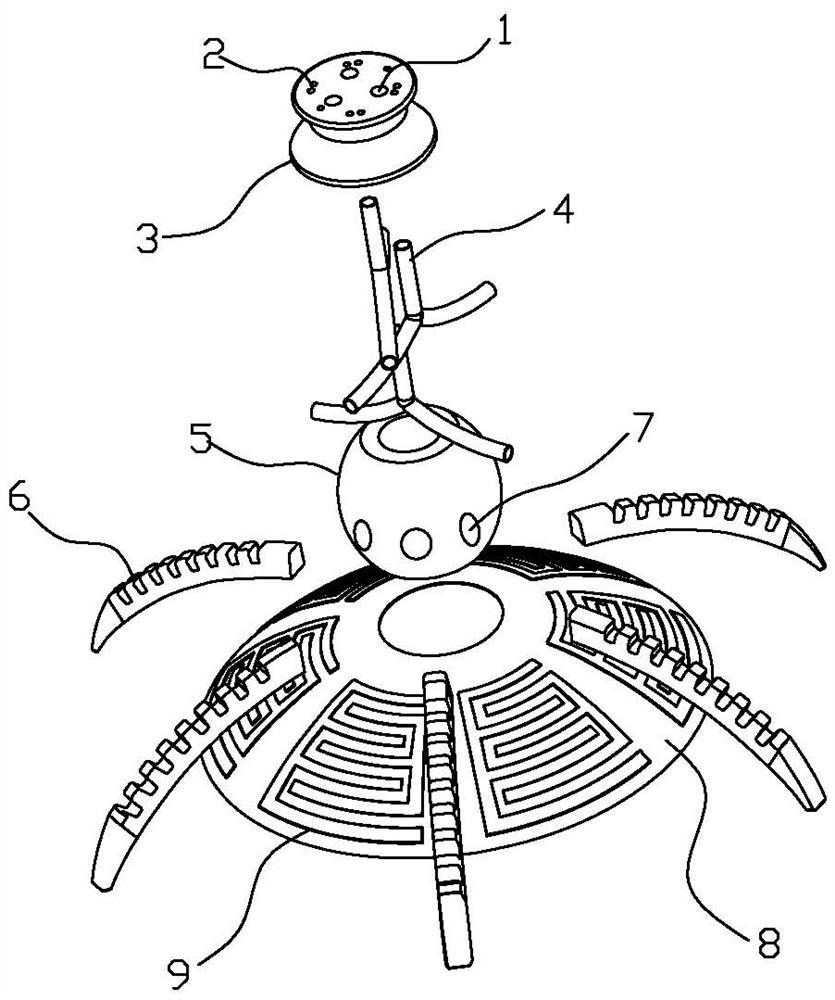

[0017] Such as figure 1 and 2 shown.

[0018] A soft electrostatic adhesion coated bionic octopus manipulator includes a connecting seat 3 , a main chamber 5 , claw fingers 6 and a coating 8 .

[0019] The connecting seat 3 is a hollow truncated cone, which can be made of metal or plastic. Its lower end is open, and its upper end surface is provided with a through inflation hole 1, which can be connected with an external air valve for inflating or pumping. There are three inflation holes 1, which are evenly arranged around the center of the connecting seat 3, which is convenient for production and installation.

[0020] The main chamber 5 is in the shape of a hollow drum and can be made of rubber. Its upper end is open and connected to the lower end of the connecting seat 3 . The periphery of the lower end of the main chamber 5 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com