A screen printing adjustable frame and screen printing screen frame

A frame and silk screen printing technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problems of scrapped screen frames, long production time of pattern boards, plastic deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

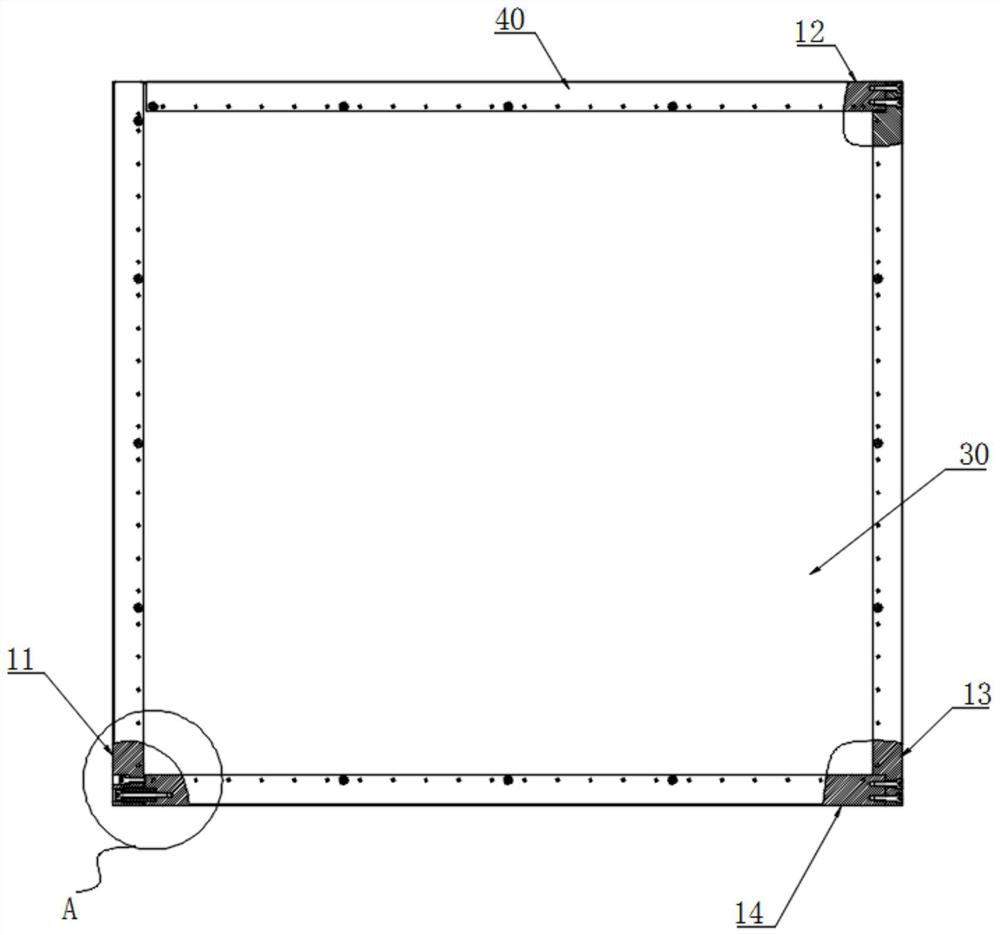

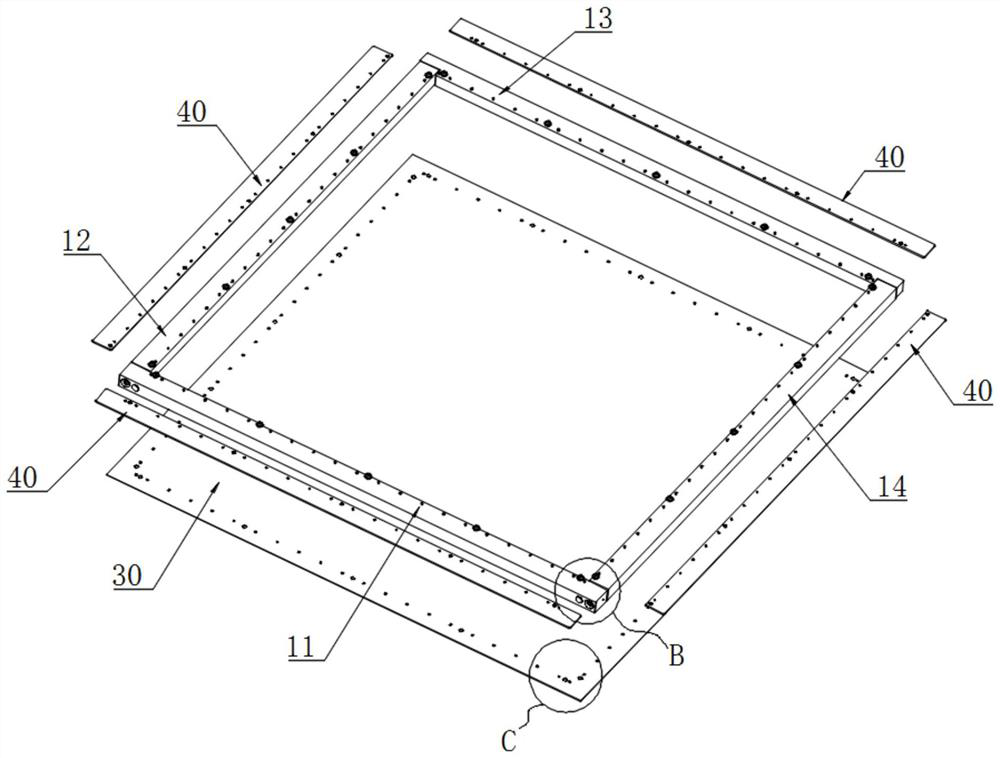

[0065] see Figure 1 to Figure 3 , a kind of screen printing screen frame of the present embodiment is a screen printing screen frame with one side adjustable, including an adjustable screen printing frame and a pattern plate 30;

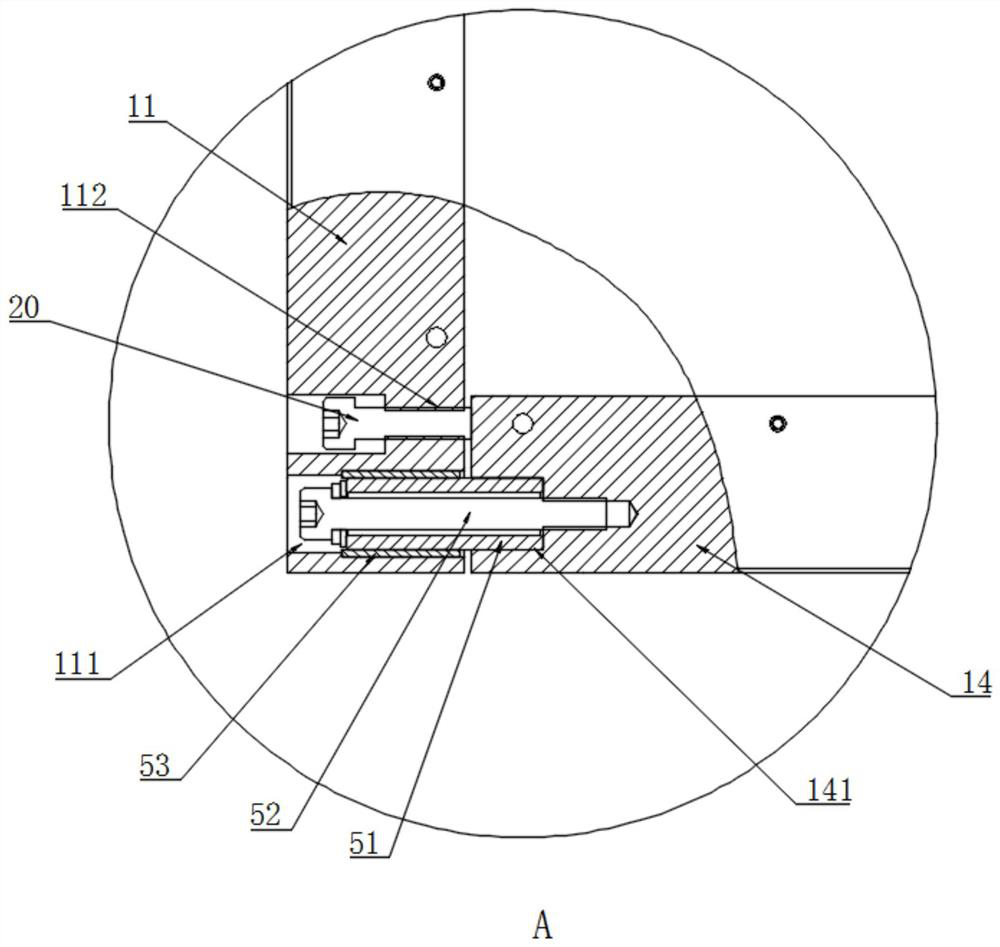

[0066] Specifically, the silk screen adjustable frame includes a first frame 11, a second frame 12, a third frame 13, and a fourth frame 14 adjacent in sequence, and the silk screen adjustable frame also includes two first adjustment parts 20 and four pressing plates 40. Two guide columns 51, two fixing screws 52; the first frame 11, the second frame 12, the third frame 13 and the fourth frame 14 are combined to form a rectangle; the second frame 12, the third frame 13 and the The fourth frame 14 is fixedly connected, and the second frame 12 , the third frame 13 and the fourth frame 14 can also be set in an integrated manner.

[0067] Specifically, both ends of the first frame 11 are respectively movably connected to one end of the second frame 12 ...

Embodiment 2

[0080] see Figure 1 to Figure 7 The difference between the second embodiment and the first embodiment is that the edge of the pattern plate 30 is not pasted with an adhesive tape layer;

[0081] Specifically, the top surfaces of the first frame 11 and the third frame 13 are provided with a plurality of first positioning pins 15; the pattern plate 30 is provided with a plurality of first holes 31 corresponding to the first positioning pins 15;

[0082] The top surfaces of the second frame 12 and the fourth frame 14 are provided with some second positioning pins 16; the pattern plate 30 is provided with some slotted holes 32 corresponding to the second positioning pins 16, and the length direction of the slotted holes 32 is in line with the The length directions of the second frame 12 or the fourth frame 14 are consistent;

[0083] In this preferred embodiment, the first hole position 31 is a special-shaped hole; the cross-sectional shape of the special-shaped hole is composed...

Embodiment 3

[0087] see Figure 1 to Figure 7 The difference between the third embodiment and the second embodiment is that the top surfaces of the second frame 12 and the fourth frame 14 are not provided with the second positioning pin 16; the pattern plate 30 is not provided with the corresponding second positioning pin 16 The long hole 32;

[0088] Specifically, the edges of the pattern board 30 corresponding to the second frame 12 and the fourth frame 14 are pasted with an adhesive tape layer.

[0089] The working process of this embodiment:

[0090] First, install the pattern board 30 on the silk screen adjustable frame, insert the first positioning pin 15 into the first hole 31, and press the first frame 11 and the third frame by the pressing plate 40 corresponding to the first frame 11 and the third frame 13 The pattern plate 30 on the position 13, and then the edges of the pattern plate 30 corresponding to the second frame 12 and the fourth frame 14 are affixed with an adhesive t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com