Coal gun radian adjusting mechanism and coal gun radian adjusting method

A technology of adjustment mechanism and adjustment method, applied in blast furnace details, steel manufacturing process, blast furnace parts and other directions, can solve the problems of different effects, unreasonable radian of coal guns, and inability to adjust the coal guns to the proper position, etc. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

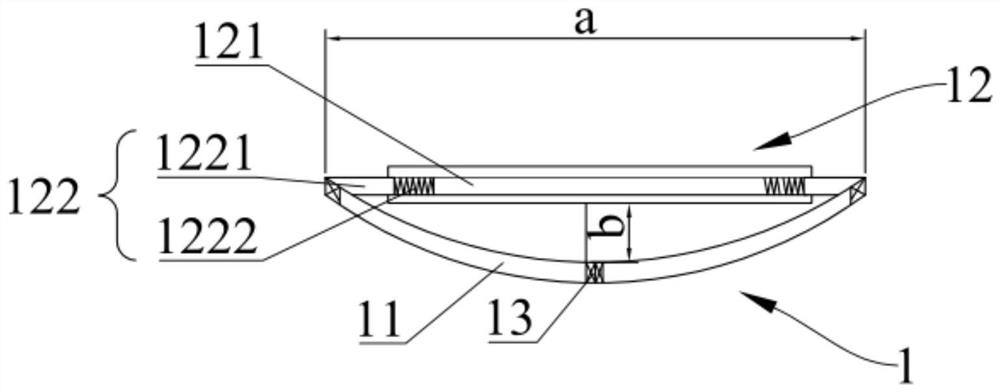

[0048] This embodiment provides a coal arc regulating mechanism. Such as figure 1 As shown, the coal radio regulating mechanism 1 includes an arcuate sleeve 11 and a tension assembly 12, and the coal gun 4 can be inserted into the curved sleeve 11, and bending and curved in the process of exiting the curved sleeve 11. The casing 11 is the same. The tensioning assembly 12 is hinged from both ends of the curved sleeve 11, and the tension assembly 12 can adjust the distance between the arc sleeve 11 to adjust the center angle of the arcuate sleeve 11.

[0049]The operator can adjust the distance between the arcuate sleeve 11 by tensioning the assembly 12 to curve the curved sleeve 11 as needed by the curved sleeve 4. The coal gun 4 is then penetrated into the curved sleeve 11, and the coal gun 4 is curved into the same radians as the arc slepens 11 in the action of the curved sleeve 11, and then the coal gun 4 can be removed. Since the arc of the curved sleeve 11 is fixed after setti...

no. 2 example

[0058] This embodiment provides a coal arc regulating method, which adjusts the curvature of the coal gun 4 using the coal arc modulation mechanism 1 in the first embodiment.

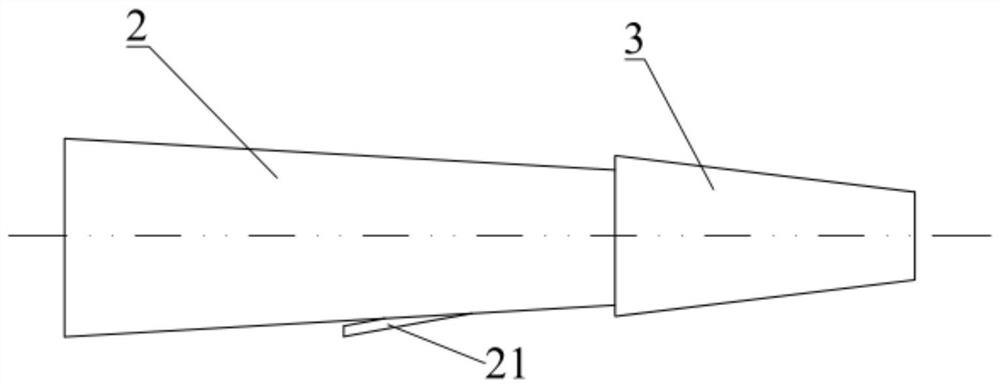

[0059] Such as Figure 1 - Figure 3 As shown, the coal reform adjustment method can adjust the curved coal insertion hole 21 inserted from the coal gun insertion tube 2 and the curved portion 41 of the coal gun 4 in the air head blowing tube 2 and the air head small sleeve 3 inserted by the coal gun. Arc adjustment methods include:

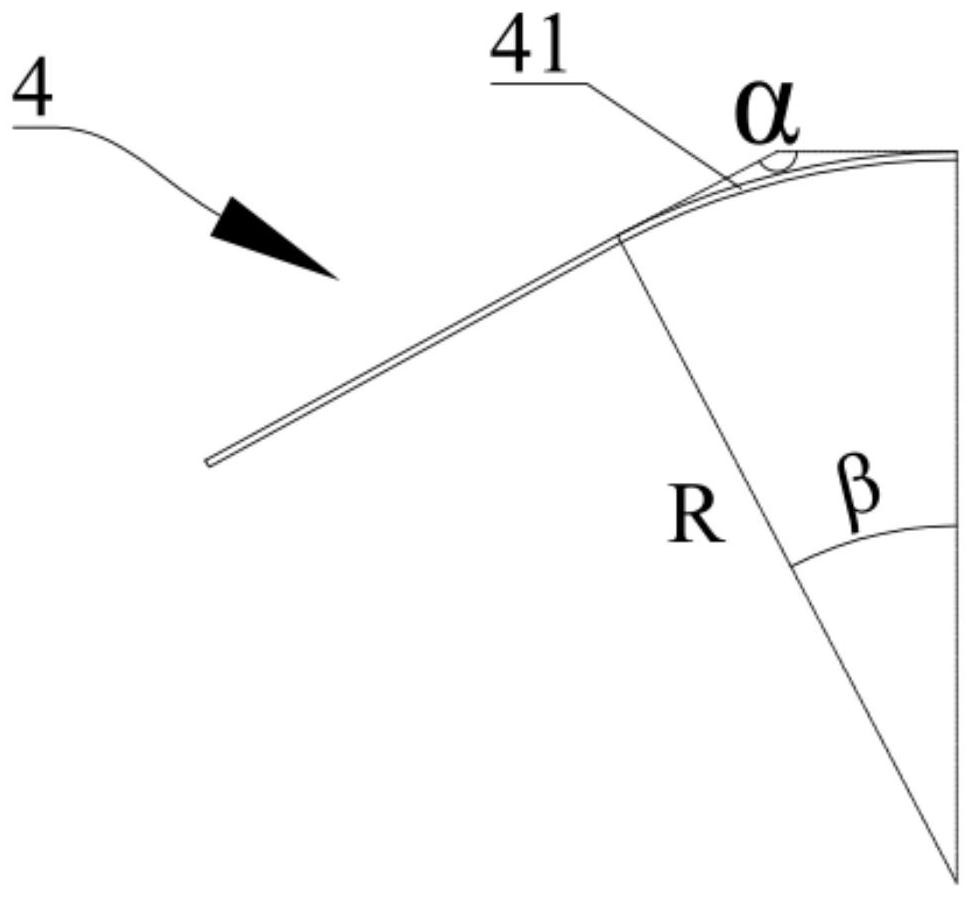

[0060] Measuring the angle α between the coal insertion hole 21 and the central axis of the air head small sleeve 3 measures.

[0061] The tensioning assembly 12 is adjusted to adjust the center angle angle of the curved sleeve 11 to β, where β = 180 ° -α.

[0062] The coal gun 4 extends from one end of the curved sleeve 11.

[0063] The coal gun 4 is taken out when the coal gun 4 is reached at the other end of the arc sleeve 11.

[0064] Since the direction of the coal insertio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com