Coal mine underground movable type gas drainage equipment

A gas drainage and mobile technology, applied in mining equipment, gas discharge, earth drilling and mining, etc., can solve the problems of inconvenient support and fixed work, inconvenient positioning and extraction, inconvenient automatic gas transportation, etc., to achieve increased protection function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

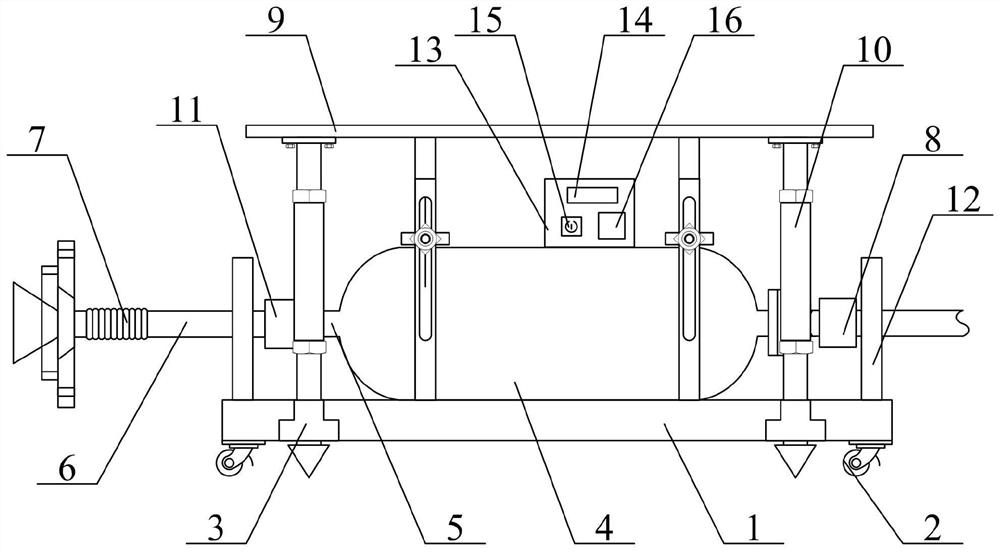

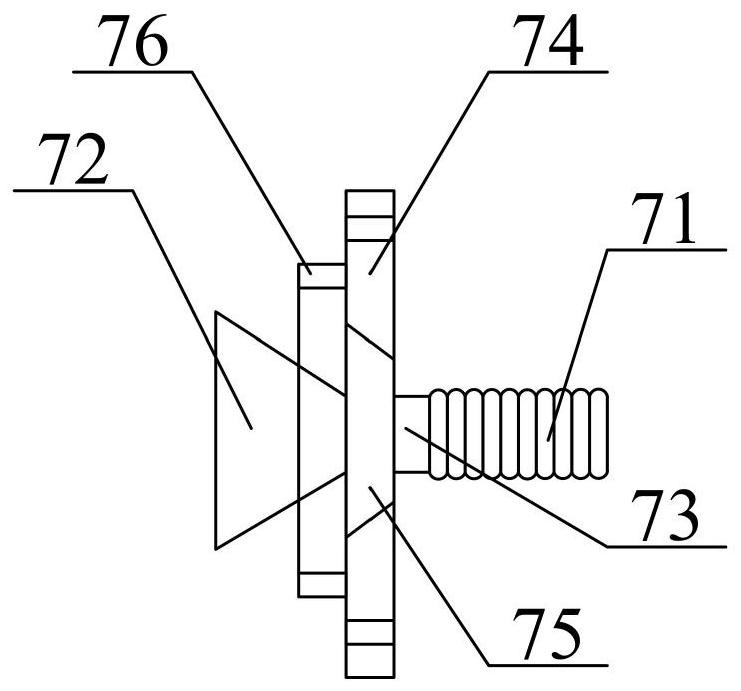

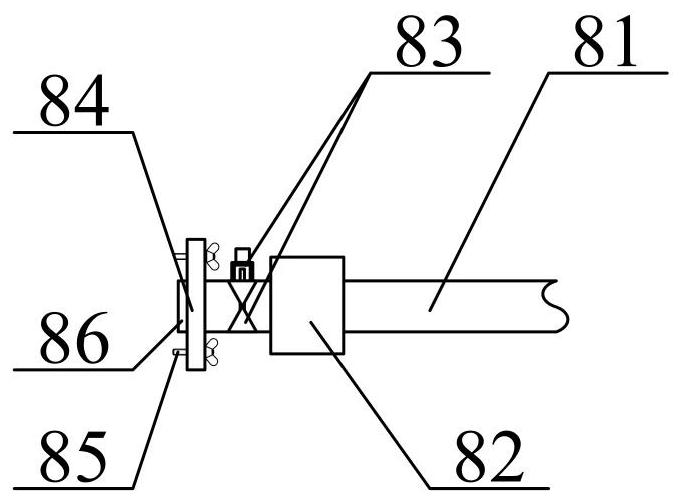

[0038] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a coal mine underground mobile gas drainage equipment includes a mobile base 1, a mobile brake wheel 2, a storage tank 3, an extraction device 4, a connecting pipe 5, a first guide pipe 6, and can be rotated, fixed, sealed, and fixed-point suction Cover structure 7, detachable automatic conveying pipe structure 8, supportable pressure-covering protective frame structure 9, rotatable support fixed rod structure 10, suction fan 11, support plate 12, control box 13, PLC14, power switch 15 and display screen 16 , the mobile brake wheels 2 are respectively bolted to the four corners of the lower end of the mobile base 1; the storage grooves 3 are respectively opened at the four corners of the mobile base 1; middle position; the connecting pipes 5 are respectively threaded in the middle positions of the left and right sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com