Heat pump unit and heat pump water heater

A heat pump unit and heat exchanger technology, applied in heat pumps, fluid heaters, refrigerators, etc., can solve problems affecting users' daily life and poor user experience, and achieve the effect of improving user experience and reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

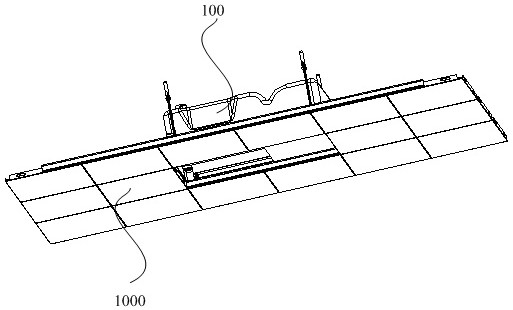

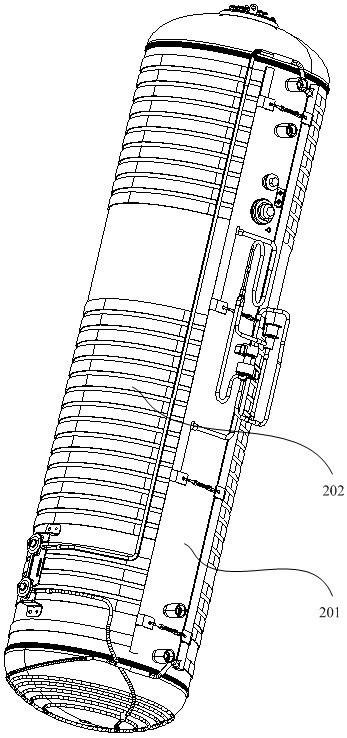

[0042] Embodiment one, such as figure 1 and figure 2 As shown, the present invention provides a heat pump water heater, which generally includes a heat pump unit 100 and a water tank 200 . The basic components of the heat pump unit 100 are a base, a compressor installed on the base, a heat exchanger, a throttling device and a fan, and the water tank 200 includes an outer shell (not shown), an inner tank 201 and an auxiliary heat exchanger 202. The compressor, the heat exchanger, the throttling device and the auxiliary heat exchanger 202 are connected to form a refrigerant circulation flow path, and the water in the inner tank 201 is heated and treated by using the principle of a heat pump. The above is the basic configuration of a conventional heat pump water heater, and will not be limited or repeated here.

[0043] During actual installation and use, the heat pump unit 100 is fixed on the indoor roof by means of hanging installation, and is hidden on the ceiling 1000 . ...

Embodiment 2

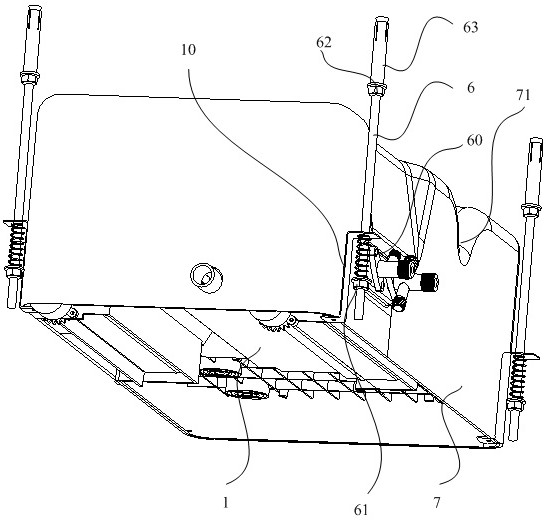

[0045] Embodiment two, such as image 3 and Figure 4 As shown, in order to effectively reduce the overall height of the heat pump unit to meet the hidden installation of the heat pump unit in the ceiling. The heat pump unit includes: a base 1 , a compressor 2 , a heat exchanger 3 and a fan 4 . In order to meet the requirements of hanging installation, the base 1 is provided with a mounting part 10 for hanging installation on the base 1; the heat exchanger 3 is arranged on the base 1; the fan 4 is used to drive airflow through the heat exchanger 3 Perform heat exchange. Wherein, in order to effectively reduce the overall height of the heat pump unit, the compressor 2 is arranged horizontally and installed on the base 1 ; the fan 4 and the heat exchanger 3 are located on the same side of the compressor 2 .

[0046] Specifically, the compressors 2 in the heat pump unit are horizontally arranged and fixedly installed on the base 1 . In this way, the height space occupied by t...

Embodiment 3

[0051] Embodiment three, such as Figure 7 As shown, since the heat pump unit is hung and installed on the indoor roof, in order to facilitate the operator to maintain the electronic control devices later, for the base 1, the upper surface of the base 1 forms the upper mounting surface, and the lower surface of the base 1 Form the lower mounting surface. Wherein, the compressor 2, the heat exchanger 3 and the fan 4 are installed on the upper installation surface of the base 1; lower mounting surface.

[0052] After the heat pump unit is hung and installed, since the electric control board 5 is installed on the lower mounting surface of the base 1, when the electric control board 5 needs to be repaired, it is only necessary to open the ceiling to face the electric control board 5 at the bottom of the base 1. Make repairs. Wherein, for the specific configuration of the electric control board 5 , reference may be made to the control circuit board in a conventional heat pump un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com