Buffering shell pressure detection device for new energy automobile production

A new energy vehicle and detection device technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, vehicle testing, etc., can solve the problems of pressure detection equipment damage, inconvenient pressure detection, and reduced service life. Achieve the effects of improving stability, improving sealing effect, improving safety performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

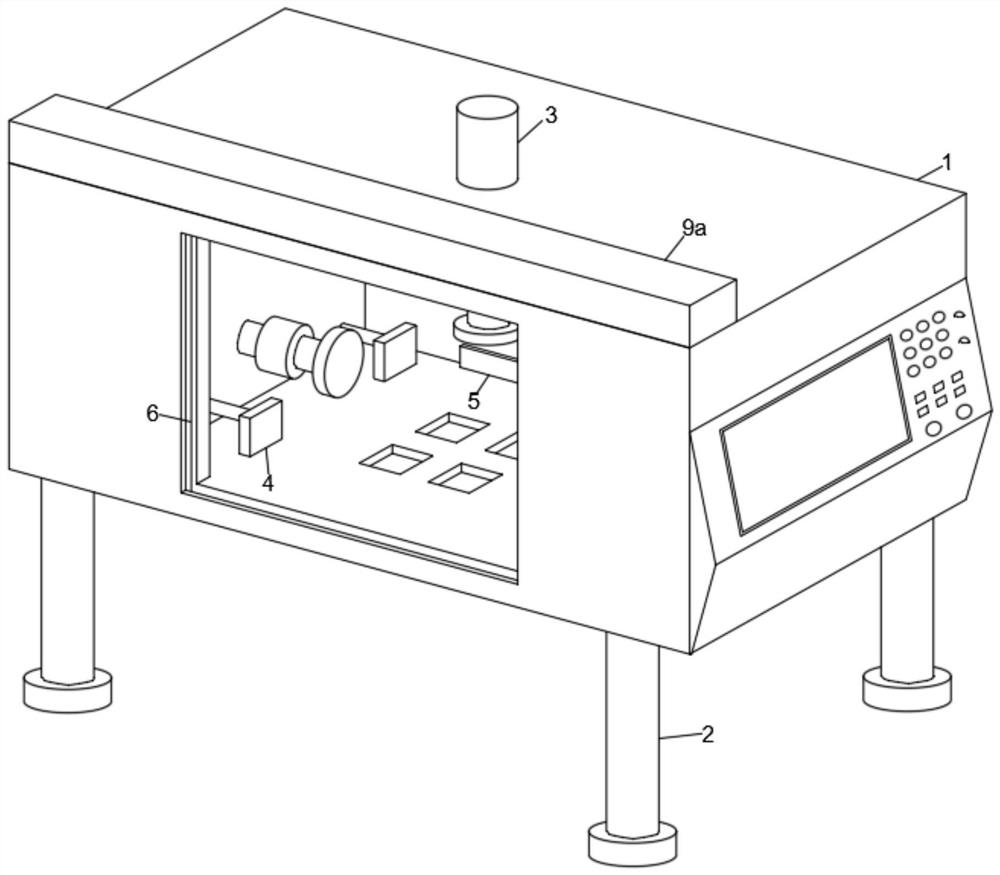

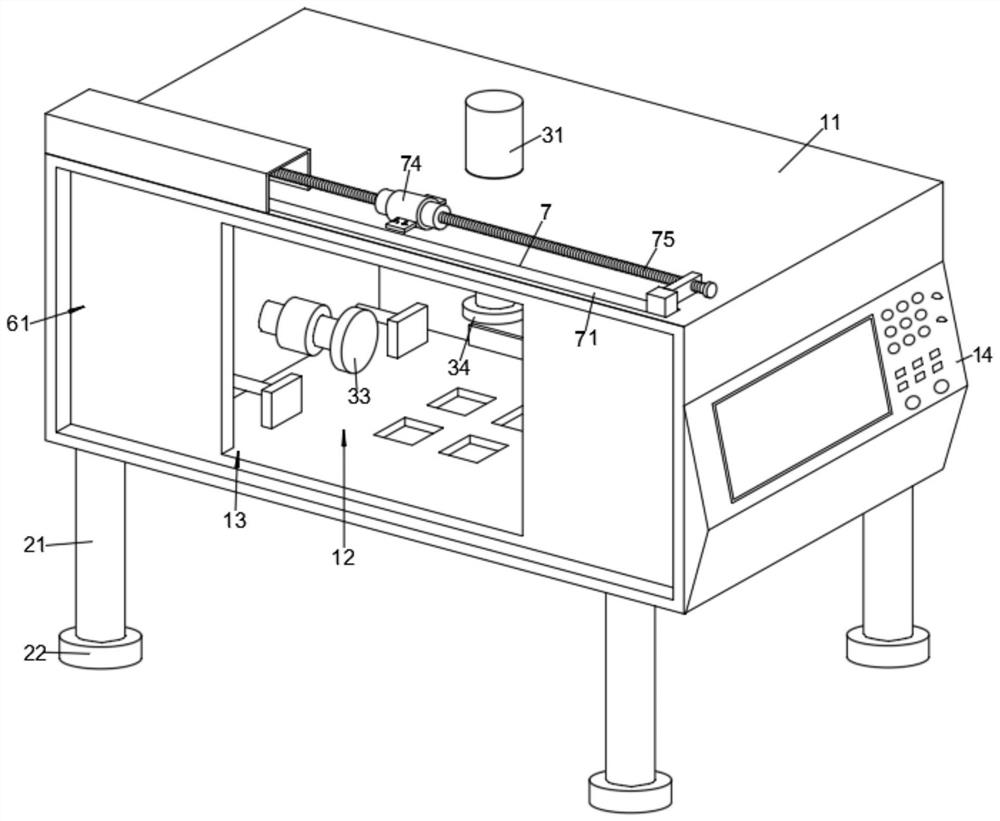

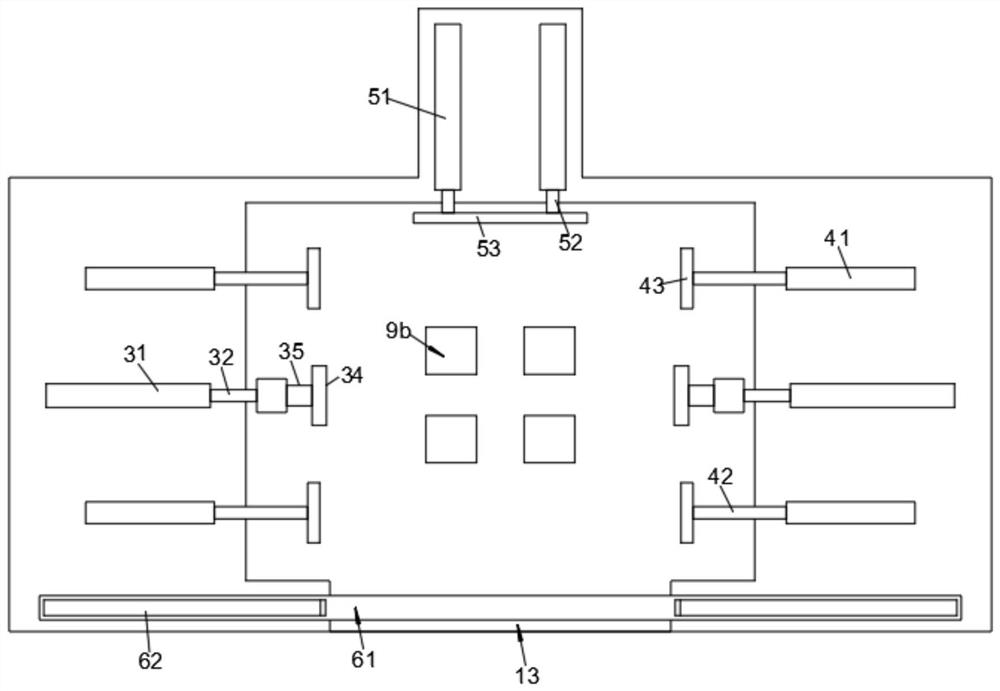

[0041] refer to Figure 1-6 , the present invention will be described in further detail below in conjunction with accompanying drawing:

[0042] refer to Figure 1-2 , the detection box 1 is used for the placement detection of the new energy vehicle shell, the detection box 1 includes a box body 11, a detection cavity 12, a feed port 13 and a control panel 14, the detection cavity 12 is opened in the box body 11, and the The feed port 13 is opened on the side wall of the box body 11 and communicates with the inside of the detection chamber 12, the control panel 14 is fixedly installed on the side wall of the box body 11, and the support mechanism 2 for supporting the detection box 1 is installed on the side wall of the detection box 1. At the bottom, the support mechanism 2 includes support columns 21 and rubber feet 22. Two sets of support columns 21 are symmetrically fixed and installed on the lower side wall of the box body 11, and two sets of rubber feet 22 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com