Method for semiconductor photoetching process

A lithography process and semiconductor technology, applied in the semiconductor field, can solve the problem of heavy-duty wafers exceeding the specification line, etc., and achieve the effect of avoiding data transmission failure, avoiding operation errors, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

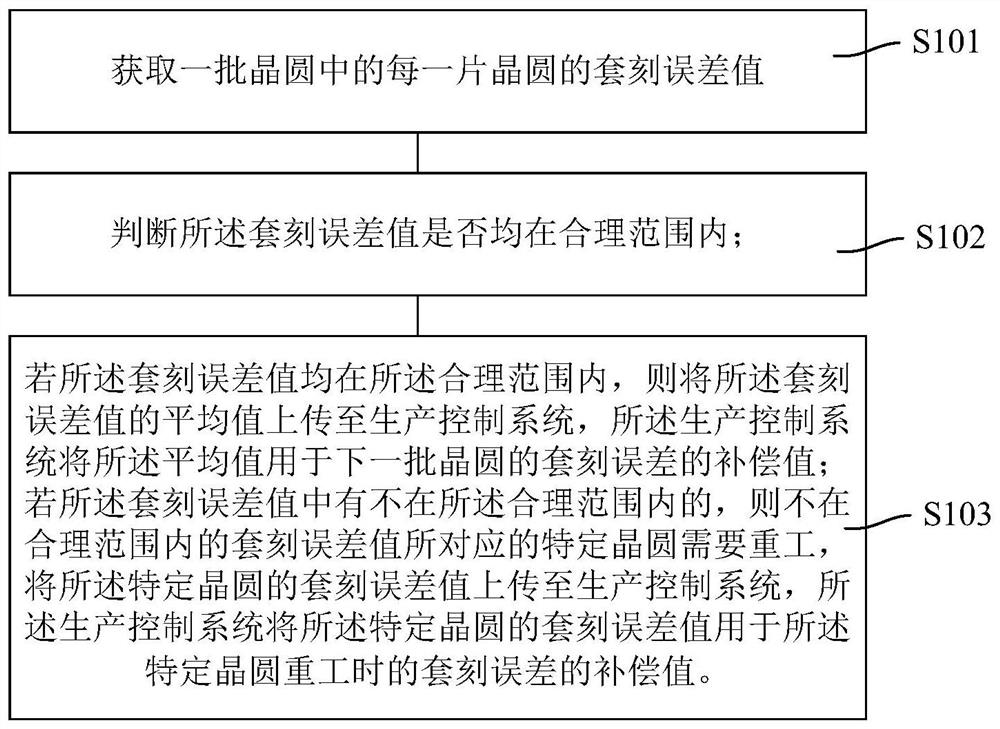

[0035] As mentioned in the background art, existing methods for reworking wafers have the situation that reworked wafers still exceed the specification line.

[0036] The study found that due to the change of the previous process or the deformation of individual wafers, the overlay error of the wafers exposed on the same chuck will be quite different. Due to the inconsistent behavior of the wafers exposed on the same chuck, the same The compensation values of the wafers in the chuck are averaged, so that the wafers that need to be reworked are not optimally compensated; the reworked wafers will continue to exceed the specification line. In one embodiment, in order to solve the aforementioned problems, it is necessary to separate the measurement values of the reworked wafers separately and resend them to the overlay compensation system so that the reworked wafers can be optimally compensated. This process is time-consuming. It is long, and the operation is complicated, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com