Equipment operation parameter short-time prediction method and system based on change rate

A technology of equipment operation and operating parameters, which is applied in forecasting, data processing applications, biological neural network models, etc., can solve the problems of short historical data, difficult practical application, inflexible accuracy, etc., and achieve the effect of simple structure and easy deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

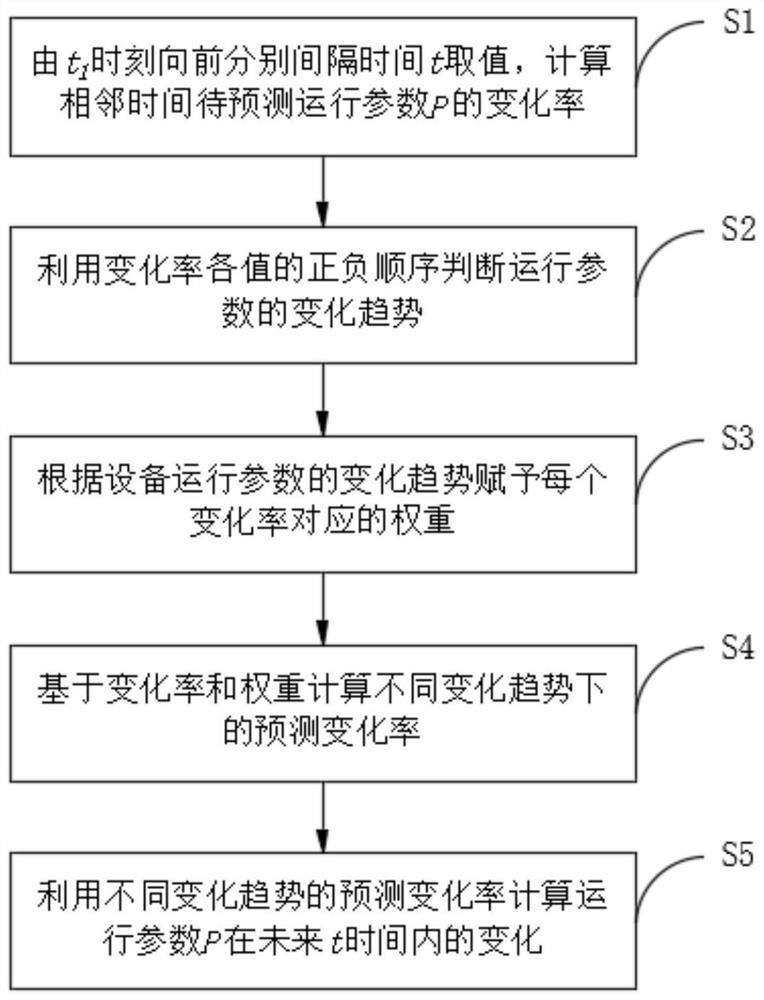

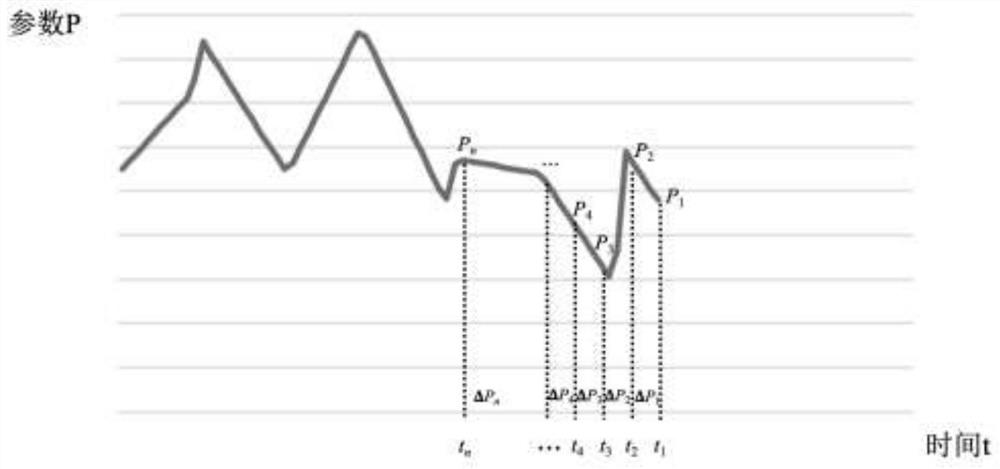

Method used

Image

Examples

Embodiment example 1

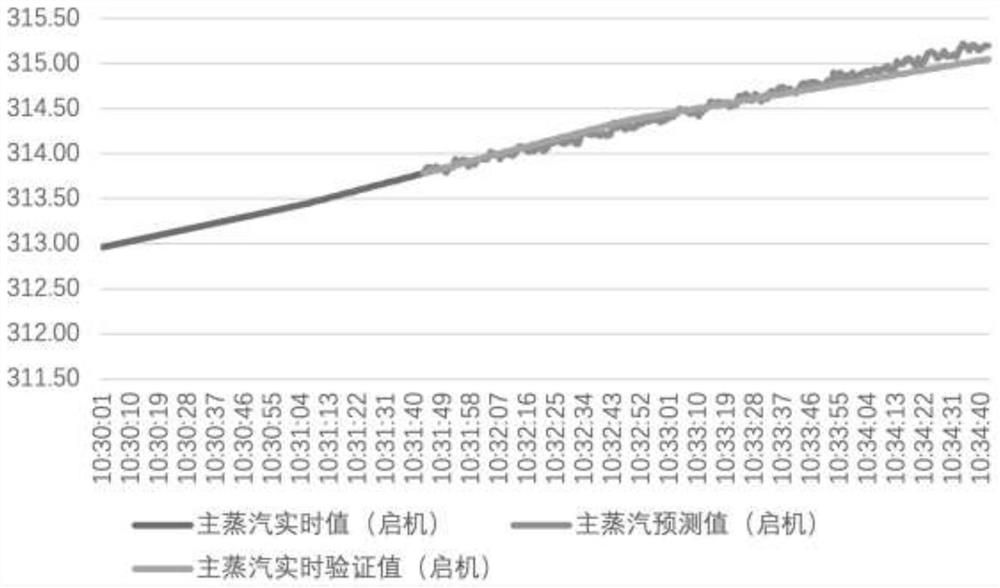

[0080] Implementation case 1. Short-term prediction of main steam temperature change when boiler starts up

[0081] Let the field take data every 1 second, and the main steam temperature T is at a certain moment t during the start-up process. 1 Take 11 values forward, namely: 313.78°C, 313.77°C, 313.76°C, 313.75°C, 313.74°C, 313.73°C, 313.72°C, 313.71°C, 313.70°C, 313.69°C, 313.68°C;

[0082] According to the calculation formula of the change rate, the change rate ΔT of the main steam temperature is obtained 1 ~ΔT 100.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s, 0.01°C / s s, the positive and negative order of the rate of change satisfies the judgment of the continuous upward trend of the parameter;

[0083] Set ΔT 1 ~ΔT 10 The corresponding weight ω 1 ~ ω 10 0.2, 0.18, 0.12, 0.10, 0.09, 0.08, 0.07, 0.06, 0.05, 0.05 respectively, then the change rate ΔT of the rising trend of the main steam temperature T is 0.01°C / s;

[0084] ...

Embodiment example 2

[0086] Implementation case 2. Short-term prediction of main steam temperature change when the boiler is shut down

[0087] Let the field take data every 1 second, and the main steam temperature T is at a certain moment t during the start-up process. 1 Take 11 values forward, namely: 427.52°C, 427.54°C, 427.55°C, 427.56°C, 427.57°C, 427.58°C, 427.60°C, 427.61°C, 427.62°C, 427.63°C, 427.64°C;

[0088] According to the calculation formula of the change rate, the change rate ΔT of the main steam temperature is obtained 1 ~ΔT 10 They are -0.02°C / s, -0.01°C / s, -0.01°C / s, -0.01°C / s, -0.01°C / s, -0.02°C / s, -0.01°C / s, -0.01°C / s, -0.01°C / s, -0.01°C / s, the positive and negative sequence of the change rate meets the judgment of the continuous downward trend of the parameters;

[0089] Set ΔT 1 ~ΔT 10 The corresponding weight ω 1 ~ ω 10 0.2, 0.18, 0.12, 0.10, 0.09, 0.08, 0.07, 0.06, 0.05, 0.05 respectively, then the change rate ΔT of the downward trend of the main steam temperature...

Embodiment example 3

[0092] Implementation case 3. Short-term prediction of steam turbine active power change during normal boiler operation

[0093] Let the field take data every 1 second, and the active power of the steam turbine at a certain time t 1 Take 11 values forward, namely: 404.96MW, 405.01MW, 405.07MW, 405.12MW, 405.18MW, 404.73MW, 404.61MW, 404.67MW, 404.72MW, 404.78MW, 404.83MW;

[0094] According to the calculation formula of the change rate, the change rate ΔtP of the active power of the steam turbine is obtained 1 ~ΔtP 10 Respectively -0.05MW / s, -0.06MW / s, -0.05MW / s, -0.06MW / s, 0.45MW / s, 0.12MW / s, -0.06MW / s, -0.05MW / s, -0.06 MW / s, -0.05MW / s, the positive and negative sequence of the change rate meets the judgment of the parameter fluctuation trend;

[0095] Set ΔP 1 ~ΔP 10 The corresponding weight ω 1 ~ ω 10 are 0.15, 0.15, 0.12, 0.12, 0.10, 0.10, 0.08, 0.08, 0.05, 0.05 respectively, then the change rate ΔP of the fluctuation trend of the active power P of the steam turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com