Electric welding smoke occupational disease hazard risk assessment method

A risk assessment and occupational disease technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems that the movement cannot be effectively controlled, the work efficiency is reduced, and the normal use of the staff is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

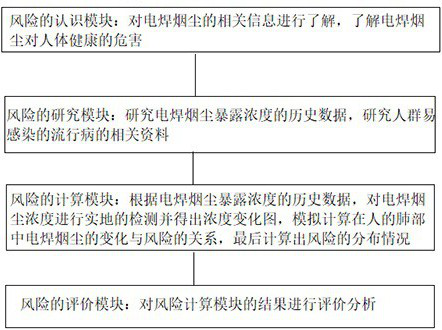

[0019] as attached figure 1 As shown, the risk assessment method for occupational disease hazards of electric welding fume, the carcinogenic risk assessment method includes four aspects: a risk recognition module, a risk research module, a risk calculation module, and a risk evaluation module. The method is as follows:

[0020] S1: Risk awareness module: understand the relevant information of welding fume, understand the hazards of welding fume to human health, investigate the basic information of the evaluated personnel, and understand the ways of welding fume exposure;

[0021] S2: Risk research module: study the historical data of welding fume exposure concentration, study the relevant data of epidemic diseases that the population is susceptible to infection, and understand the zoological experiments related to welding fume;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com