Cooling device, cooling method and method of manufacturing semiconductor package

A technology of cooling device and cooling method, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of over-baking, time-consuming, difficult to form solidified film, etc., and achieve high-quality manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

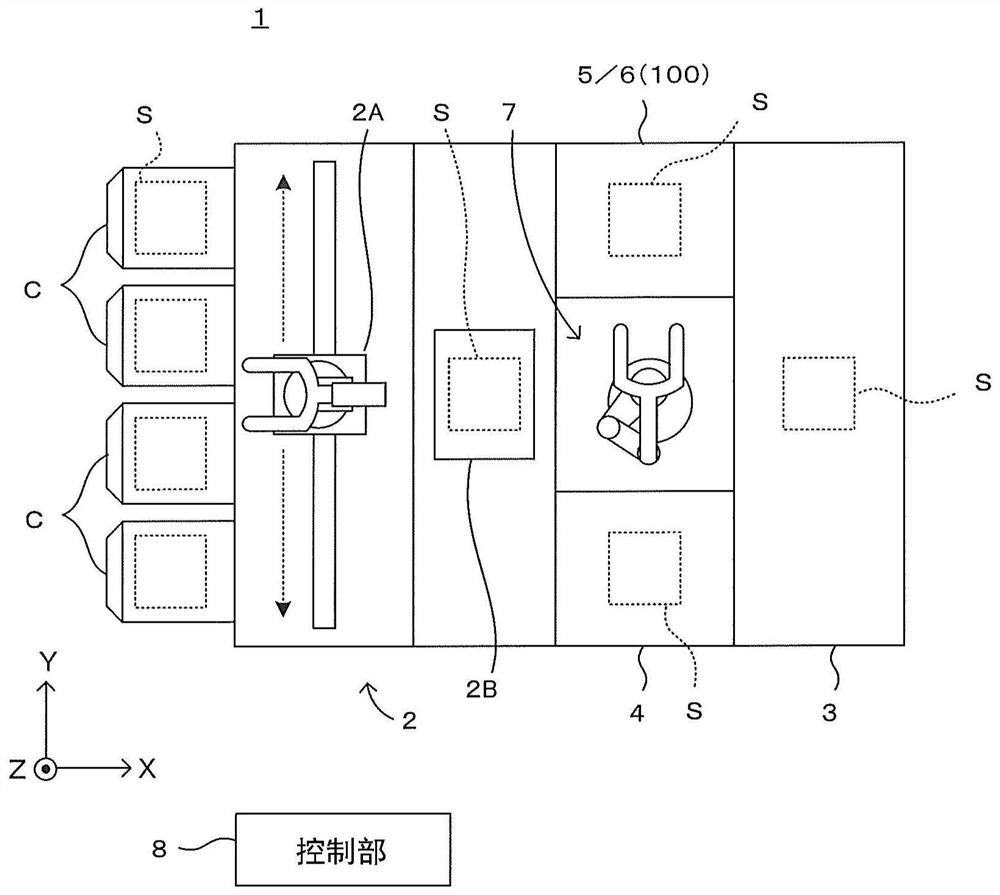

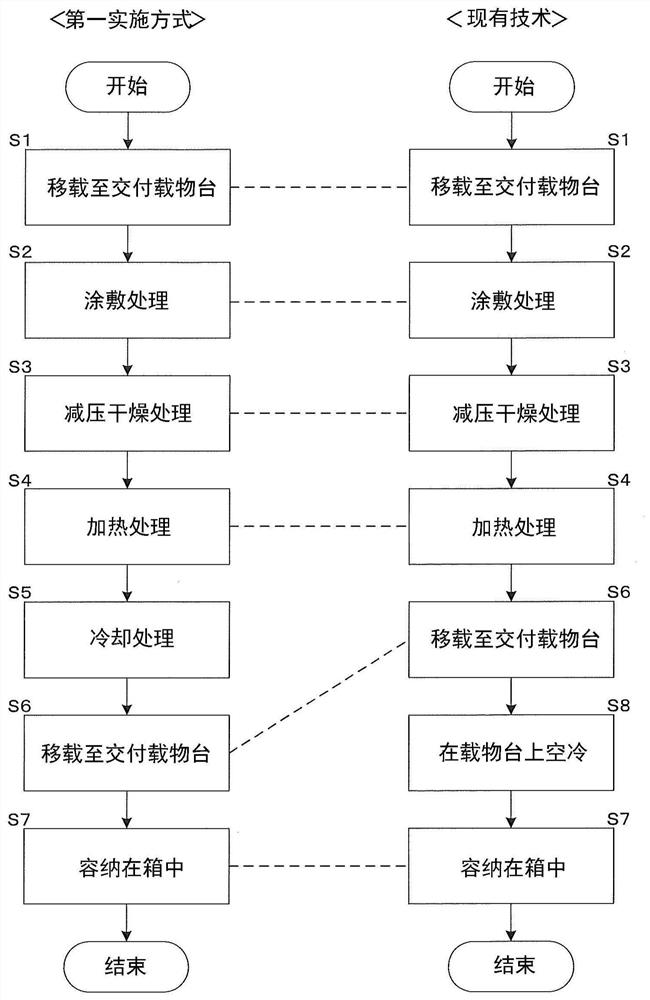

[0053] The substrate processing apparatus equipped with the cooling part which is an example of the cooling apparatus of this invention performs the pre-exposure process which is a part of manufacture of a semiconductor package, before exposing and developing a board|substrate. In particular, the substrate processing apparatus has a technical feature of cooling the substrate by a cooling unit with a correction function at the final stage of the pre-exposure process as will be described in detail later. Hereinafter, after explaining the overall structure and schematic operation of the substrate processing apparatus, the structure and operation of the cooling unit will be described in detail.

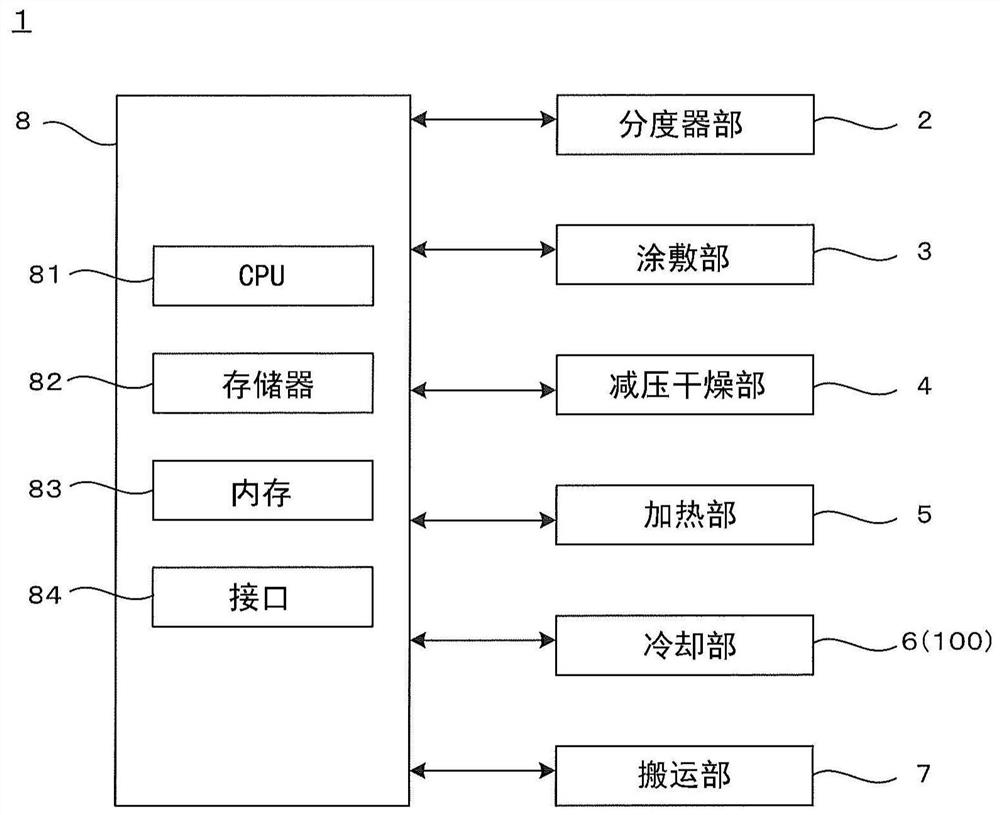

[0054] figure 1 It is a plan view showing the overall structure of a substrate processing apparatus equipped with a cooling device according to a first embodiment of the present invention. in addition, figure 2 yes means figure 1 A block diagram of the electrical structure of the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com