Power vehicle brake disc and preparation method thereof

A vehicle braking and power technology, applied in the direction of brake discs, mechanical equipment, gear shifting mechanisms, etc., can solve the problems of easy falling off, restriction, and the problem of mesh ceramic closed pores cannot be effectively solved, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

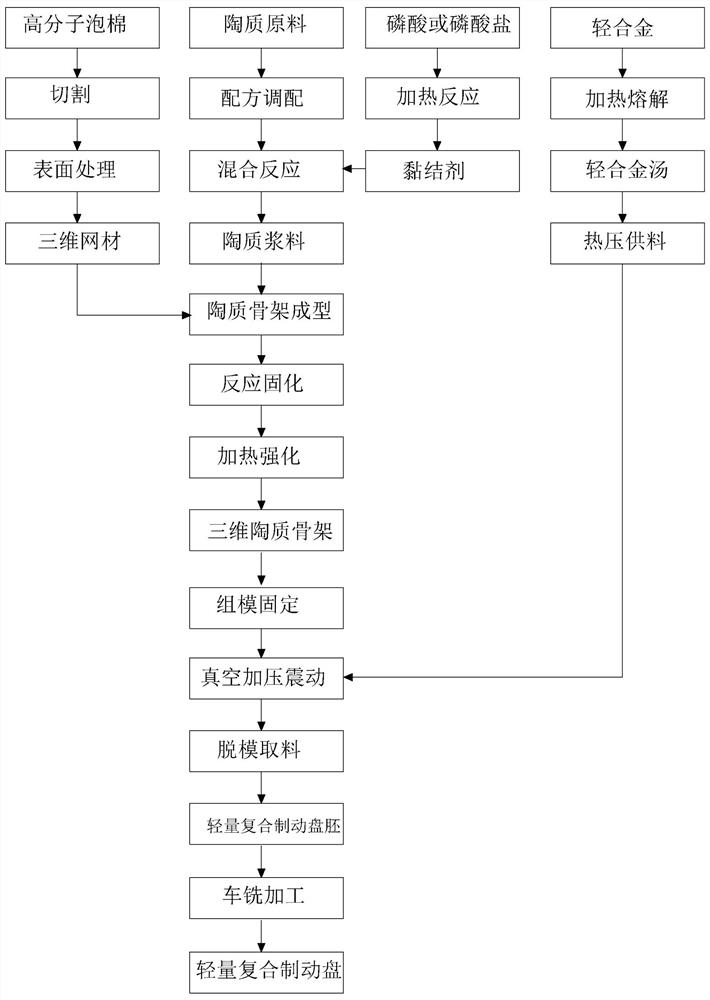

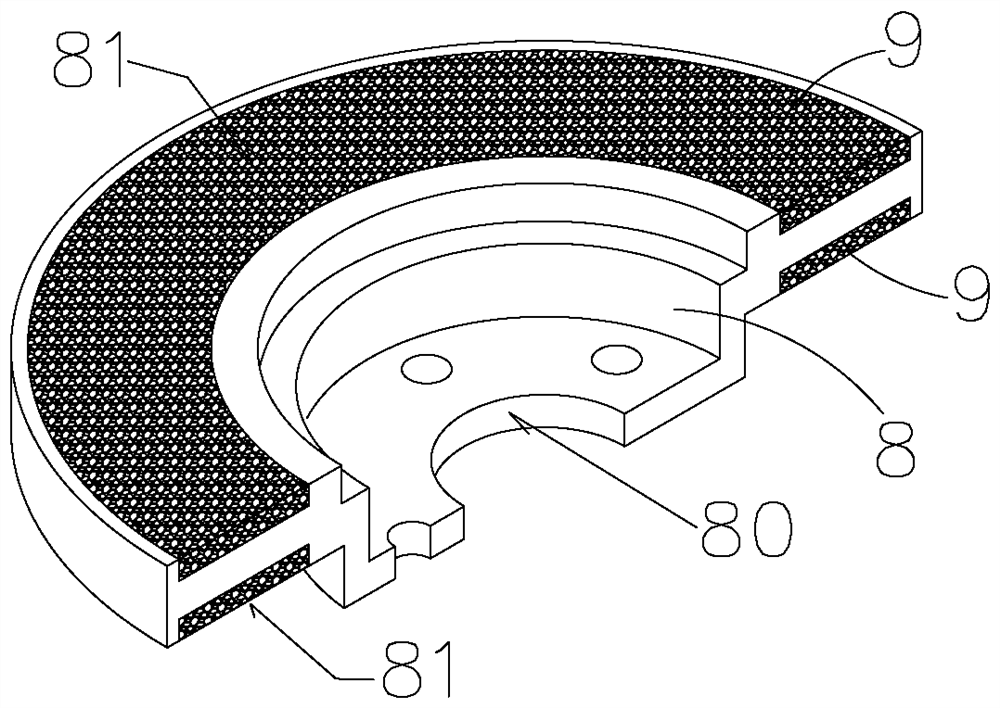

[0025] The invention is directed to a power vehicle brake disc, especially a lightweight composite brake disc and a preparation method thereof. see figure 1 and figure 2 Shown, the inventive method mainly comprises:

[0026] Three-dimensional net material preparation, after polyurethane macromolecule is foamed into three-dimensional pore foam, then cut into predetermined shape, size, thickness (the present invention is cut into a ring), and then surface treated for future use if necessary;

[0027] Binder preparation, the phosphoric acid or phosphate, aluminum hydroxide and water prepared according to the proportion are stirred and heated to react into a sol for later use; for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com