Vertical cavity surface emitting laser based on liquid crystal regulation, and preparation method thereof

A vertical cavity surface emission, laser technology, applied in lasers, laser parts, semiconductor lasers and other directions, can solve the problems of unadjustable, complex epitaxial growth, structural etching and high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

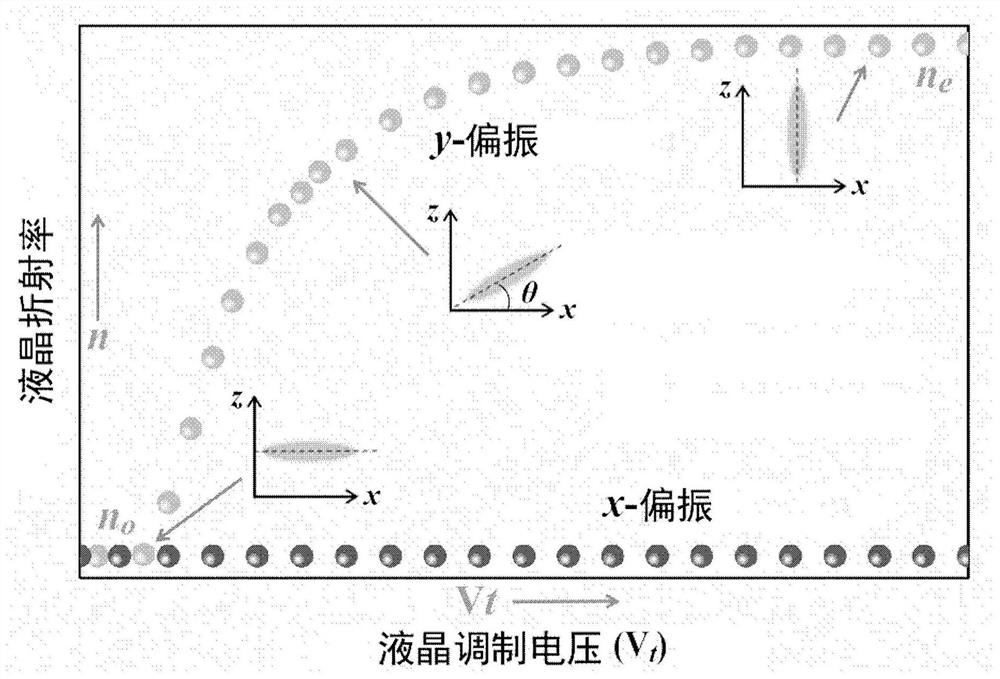

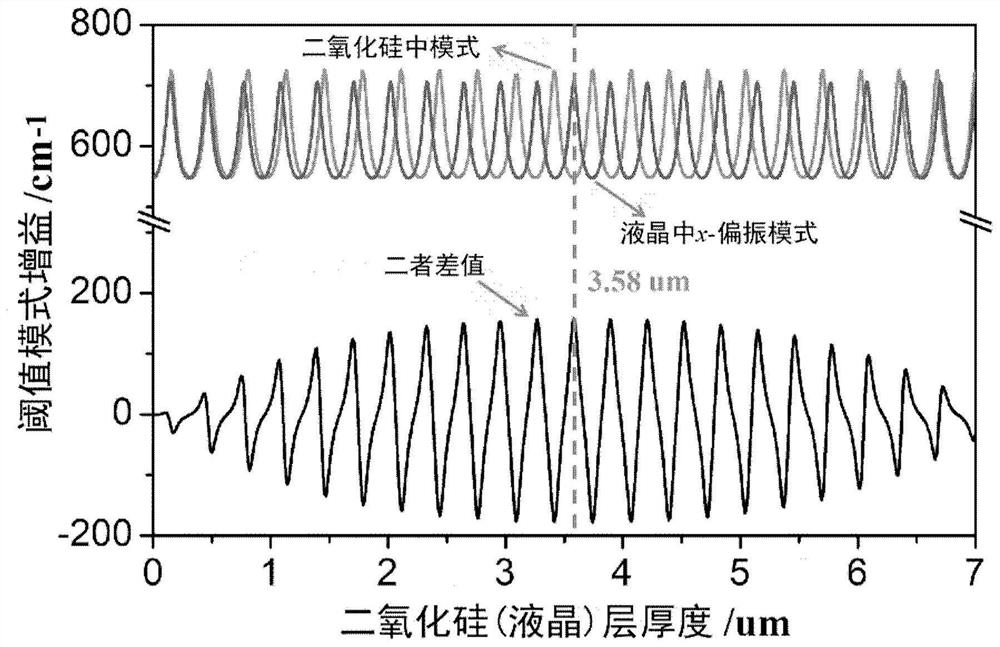

[0046] In order to solve technical problems such as the flexible control of the VCSEL transverse lasing mode in the prior art, the present invention provides a liquid crystal-based mode-tunable vertical cavity surface emitting laser and its preparation method, which can be used according to the working state and needs of the laser. The output mode is dynamically regulated without being highly dependent on the precision of the surface anti-phase structure, and has a certain adjustable range, which can overcome the related shortcomings and deficiencies of the existing vertical cavity surface emitting lasers.

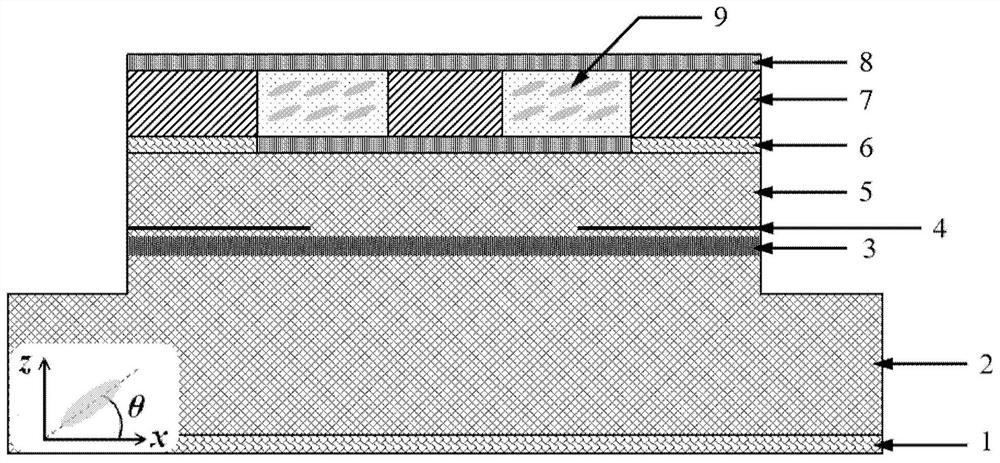

[0047]The invention is a vertical cavity surface emitting laser based on liquid crystal control. Specifically, the structure of the laser described in the present invention can be divided into two parts, one part is a traditional oxidation-limited vertical cavity surface emitting laser structure, and the other part is a liquid crystal mode modulation structure. Among them,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com