One-time synchronous resin hole plugging method for double-sided back drilling plate

A technology of resin plugging and back drilling, which is applied to the formation of electrical connections of printed components, electrical components, printed circuits, etc., can solve the problems of resin plugging bubbles, hole depressions, and plug holes that are not full, so as to ensure that the plug holes quality, inhibiting ink drop, avoiding the effect of plug hole not full and orifice sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

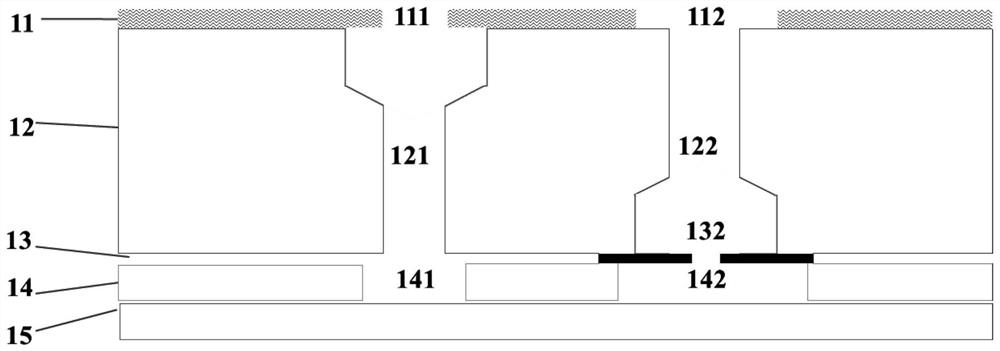

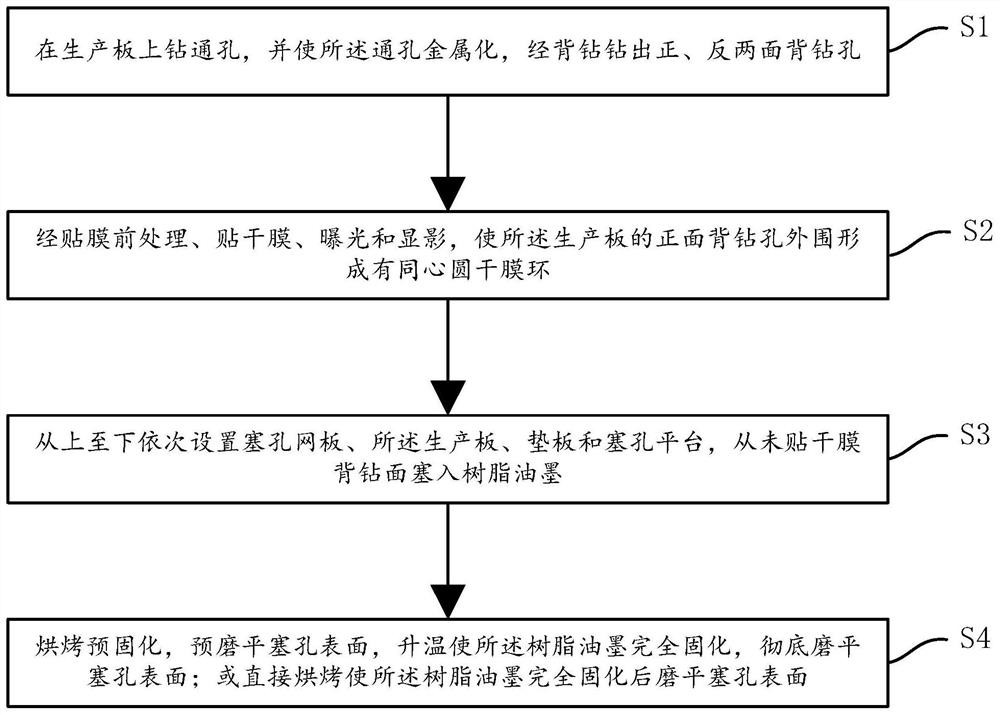

[0037] see figure 2 As shown, this embodiment provides a one-time synchronous resin plugging method for a double-sided back-drilled board, including the following steps:

[0038] S1. Drill a through hole on the production board with a diameter of 0.20mm, and metallize the through hole. Drill the reverse back drill hole 121 and the front back drill hole 122 through the back drill, and the back drill hole and the back drill part have an aperture diameter of 0.40mm;

[0039] S2. After applying dry film, exposing and developing, a concentric dry film ring 132 is formed on the periphery of the back-drilled hole on one side of the production board. The diameter of the outer ring is 0.60 mm, and the diameter of the inner ring is 0.15 mm. The dry film is produced stop production board;

[0040] S3. Set up the plug hole screen 11, the dry film blocking point production board, the backing plate 14, and the plug hole platform 15 sequentially from top to bottom, and use a plug hole mach...

Embodiment 2

[0051] see figure 2 As shown, this embodiment provides a one-time synchronous resin plugging method for a double-sided back-drilled board, including the following steps:

[0052] S1. Drill through holes on the production board with a diameter of 0.25 mm, and metallize the through holes. The production board is double-sided back-drilled to form back-drilled holes 121 on the back side and back-drilled holes 122 on the front side. The back-drilled part of the back-drilled hole has a diameter of 0.45 mm. mm;

[0053] S2. After applying dry film, exposing and developing, a concentric dry film ring 132 is formed on the periphery of the back-drilled hole on one side of the production board. The diameter of the outer ring is 0.60 mm, and the diameter of the inner ring is 0.20 mm. The dry film is produced stop production board;

[0054] S3. Set up the plug hole screen 11, the dry film blocking point production board, the backing plate 14 and the plug hole platform 15 sequentially fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com