Integrated radiator

A heat sink, integrated technology, applied in the direction of cooling/ventilation/heating transformation, modification with liquid cooling, electrical components, etc., can solve the problems of affecting heat dissipation effect and low heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

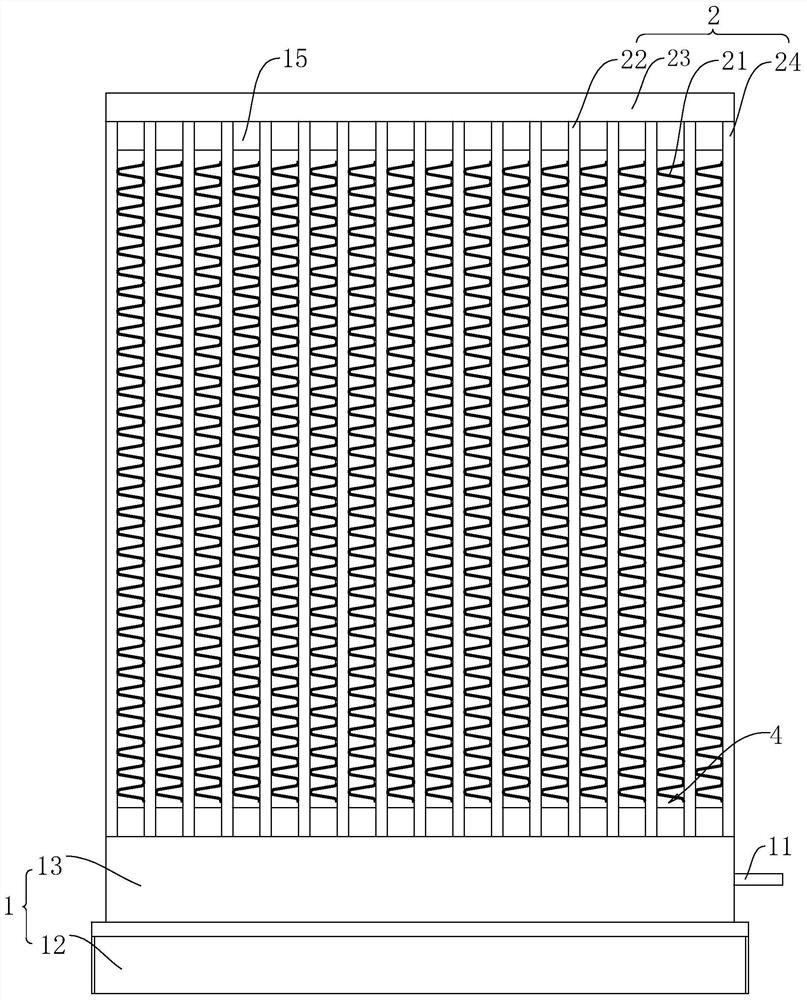

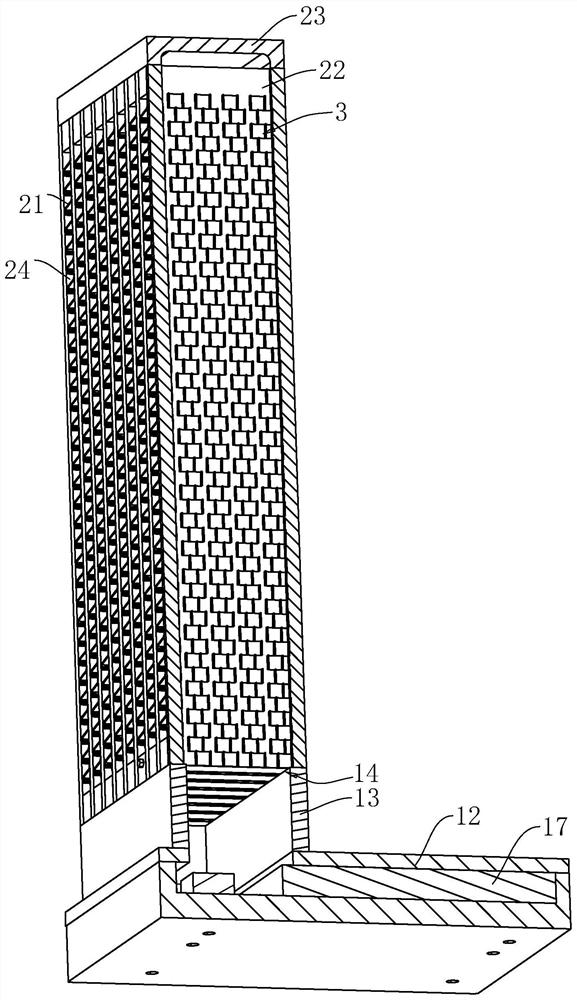

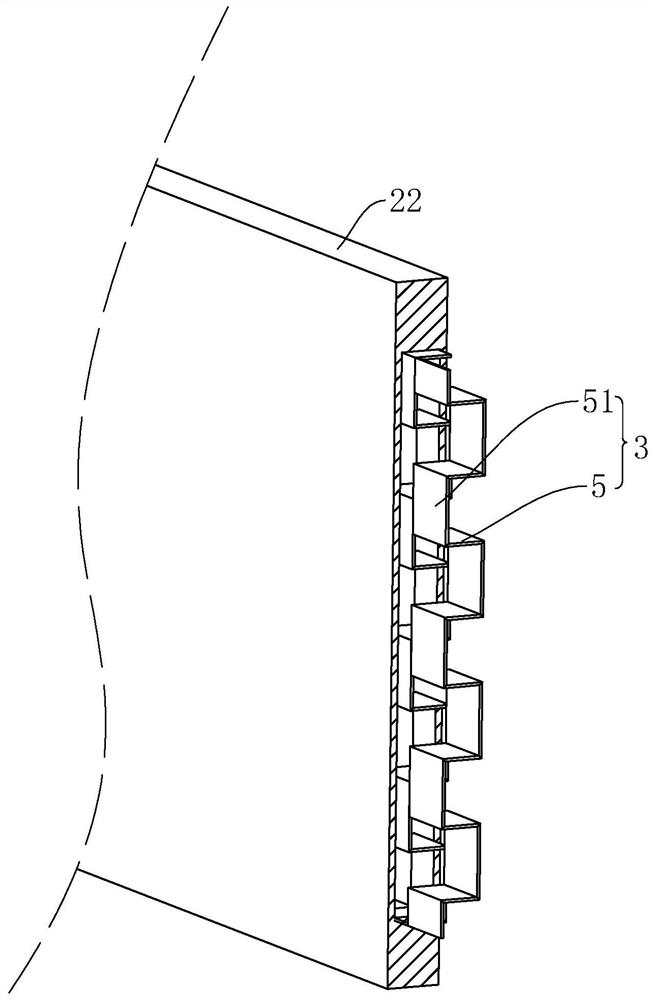

[0027] Contraction below Figure 1-3 Further detailed description of the present application.

[0028] This application example discloses a one-piece radiator.

[0029] Refer figure 1 , figure 2 The integrated heat sink includes an evaporation chamber 1, which is connected to the condenser 2 of the evaporation chamber 1, and the evaporation chamber 1 side is provided with a liquid inlet 11 in the evaporation chamber 1, and the working body is passed into the evaporation chamber 1. In the present embodiment, the condenser 2 includes a plurality of spaced heat sink 21, a plurality of connecting passages 22, a set channel 23, and two guards 24, two. One end of the guard plate 24 is welded to one end of the set channel 23 away from each other, and the other end is welded to one end of the evaporation chamber 1, and the two guard plates 24, the set passage 23, and the evaporation chamber 1 synthesize a receiving chamber 4, heat dissipating fins 21 and connectivity. The channel 22 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com