Full-automatic traction machine for wide and thick plate production in steel mill

A fully automatic technology for wide and thick plates, applied in the field of automatic tractors, can solve the problems of lower yield rate, easy damage to the traction device, and inability to center the steel plate in the limit position, so as to improve the service life, improve the traction effect, and increase the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

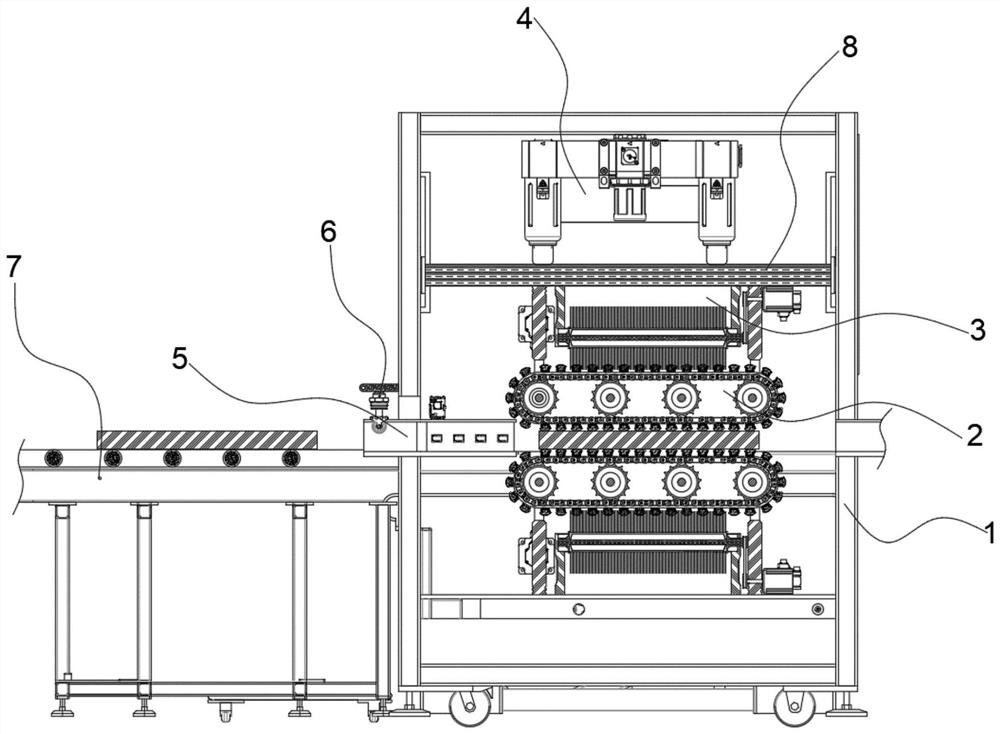

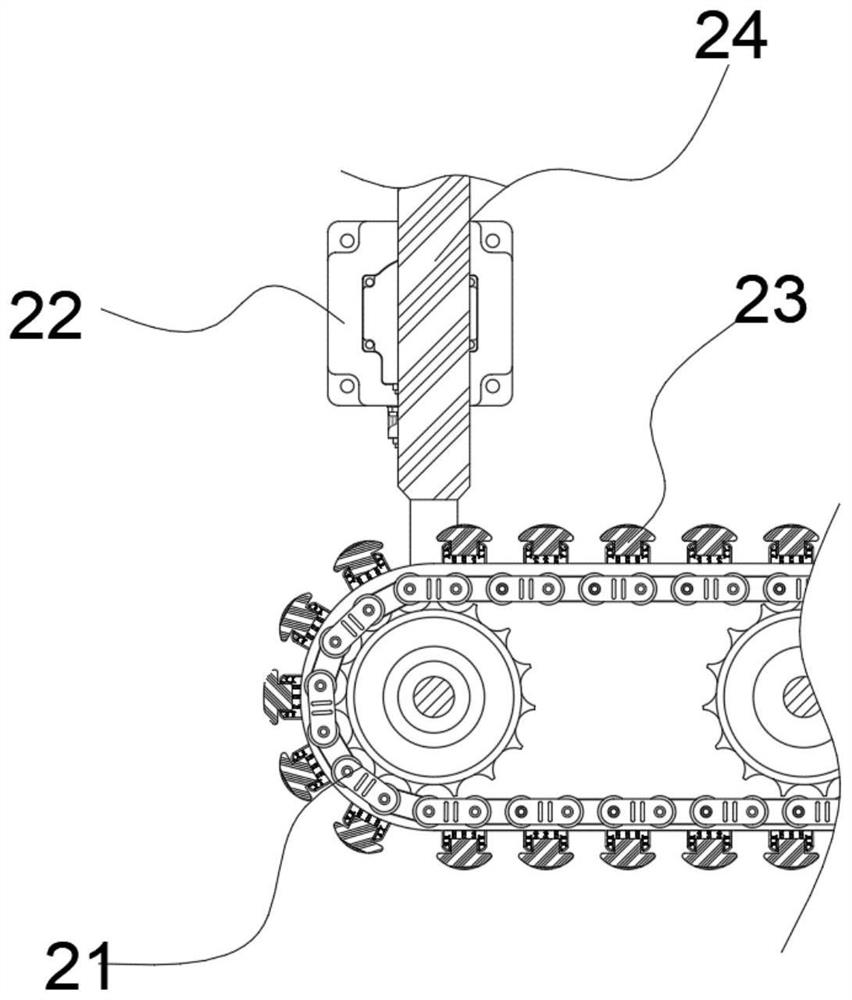

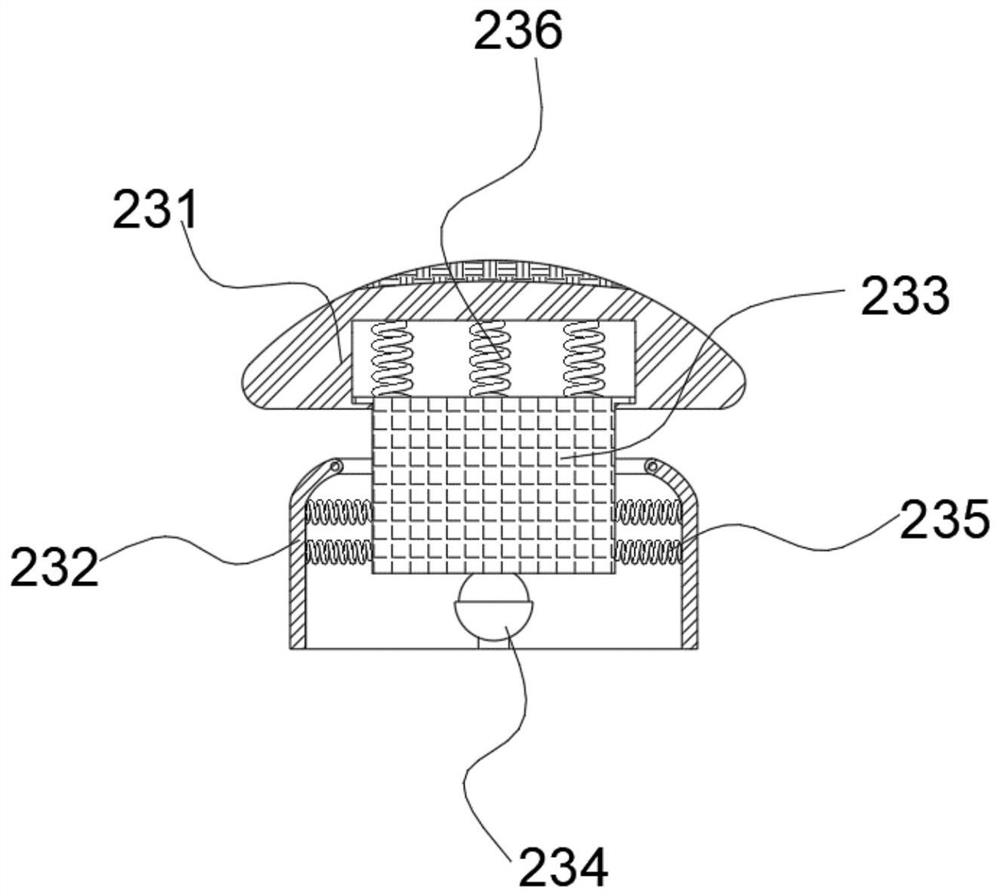

[0033] see figure 1 , in an embodiment of the present invention, a fully automatic tractor for the production of wide and thick plates in steel mills, which includes a work frame 1, a traction assembly 2 and a cleaning assembly 3, wherein the traction assembly 2 is provided with two groups, and the upper and lower Symmetrically installed in the middle of the work frame 1, so that the steel plate passes between the two traction assemblies 2; the upper end of the traction assembly 2 located above is fixed on the hanging plate 8 through the left and right symmetrical partitions 24, and the hanging plate 8 The left and right ends are slidingly arranged on the side wall of the work frame 1, and the cylinder 4 installed on the top wall of the work frame 1 drives to slide; the side of the traction assembly 2 away from the steel plate is provided with a cleaning assembly 3, and the work frame There are through holes in the middle of the left and right sides of 1, so that the steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com