Molten iron pretreatment slagging-off device and method

A technology for molten iron pretreatment and slag removal, which is applied in the fields of metallurgical equipment and equipment and molten iron pretreatment and slag removal devices, can solve problems such as affecting the efficiency of slag removal, and achieve the effects of simple structure, improved production rhythm, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

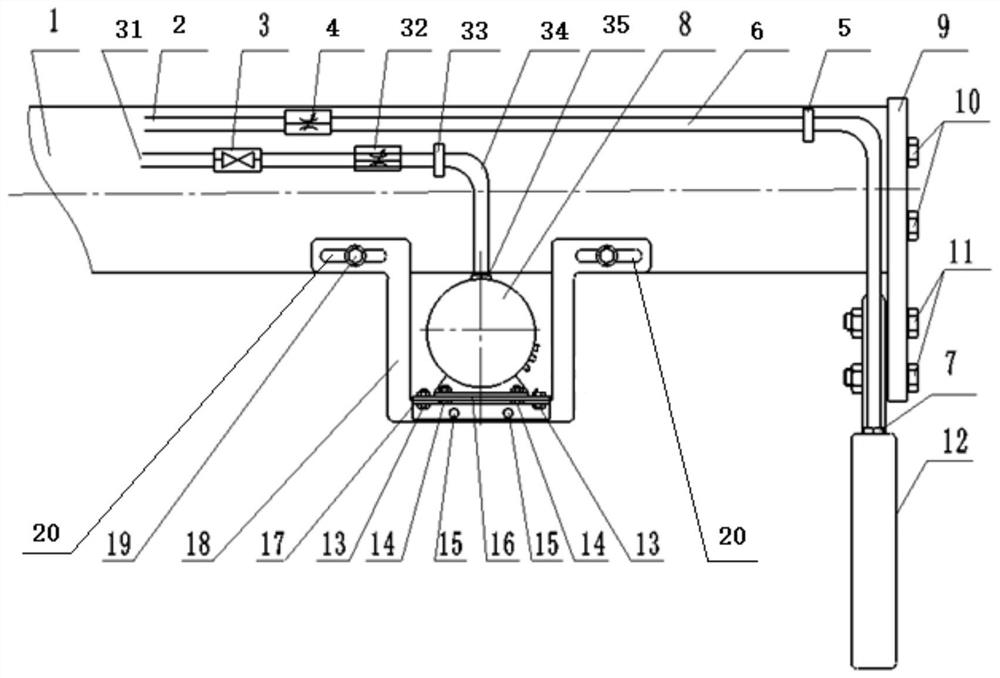

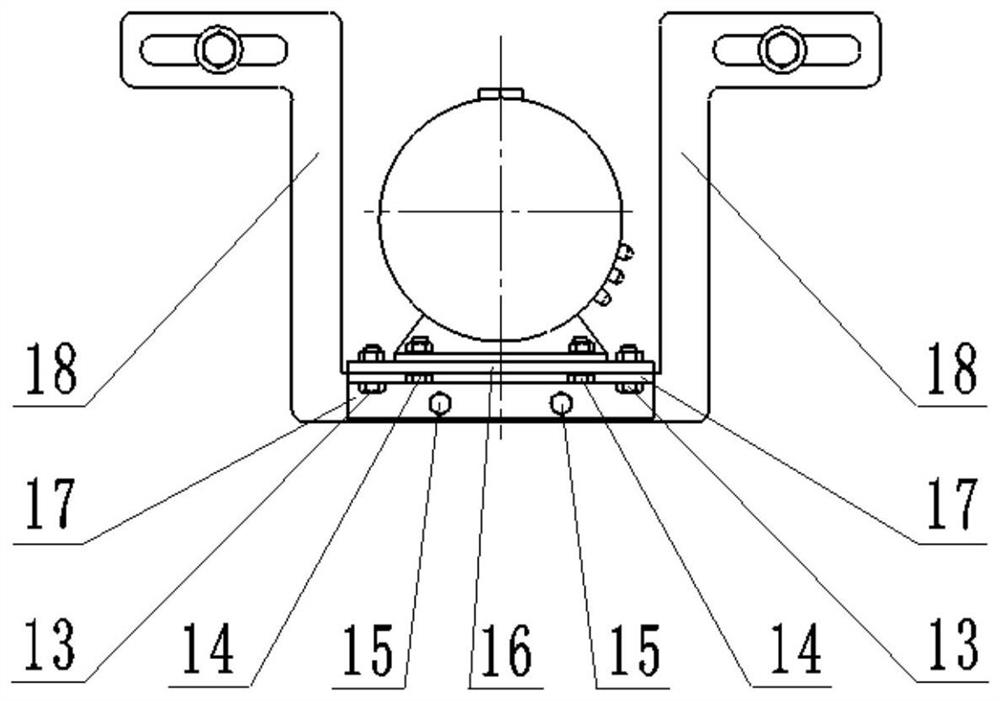

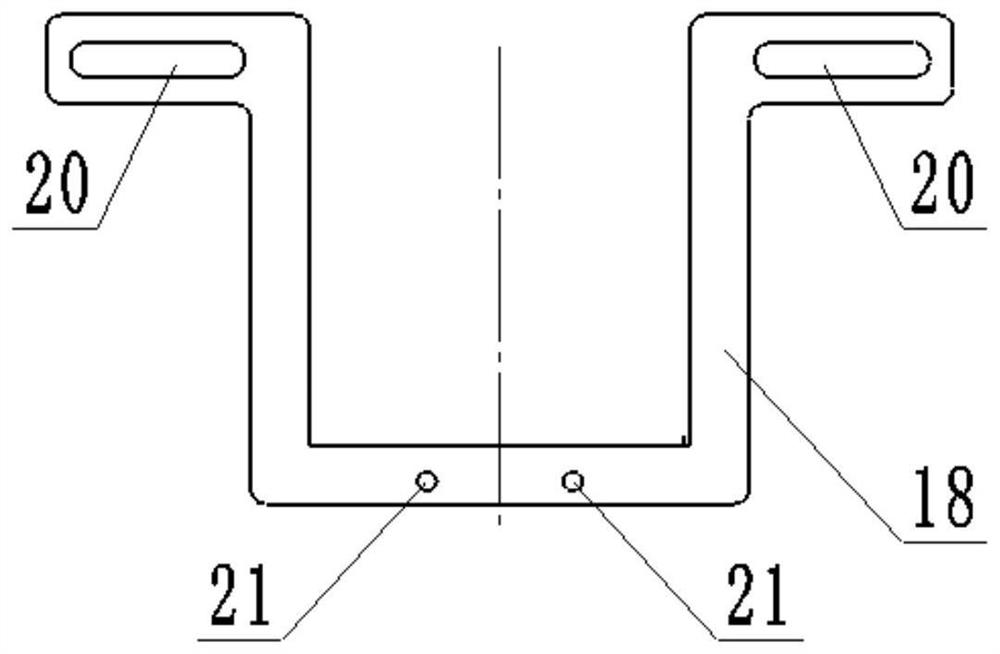

[0034] A method for removing slag in pretreatment of molten iron, the step of removing slag is:

[0035] Intake nozzle 2. Intake nozzle 31 is communicated with the nitrogen pipeline and connected with high-pressure nitrogen;

[0036] Adjust the pressure regulating valve 4. Keep the nitrogen pressure at the air outlet 30 at 0.3MPa, and slowly approach the slag removal plate 12 to the iron slag liquid level, so that the nitrogen gas is sprayed out from the air outlet 30 to blow away the iron slag around the slag removal board 12, away from the slag removal board 12;

[0037] Slowly insert the slag removal plate 12 into the iron slag liquid level, and adjust the pressure regulating valve 4. Keep the nitrogen pressure at the gas outlet 30 at 1.0 MPa, so that the nitrogen gas from the gas outlet 30 is blown into the iron slag and molten iron to form nitrogen bubbles. During the process of floating up in the molten iron and iron slag, the nitrogen gas bubbles drive the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com