Laser-assisted friction stir additive welding tool and device

A friction stir and laser-assisted technology, which is applied in the direction of additive processing, manufacturing tools, welding equipment, etc., can solve the problem of not being able to protect the tool handle well from heat, achieve high-speed friction stir additive manufacturing, reduce system redundancy, reduce The effect of the control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

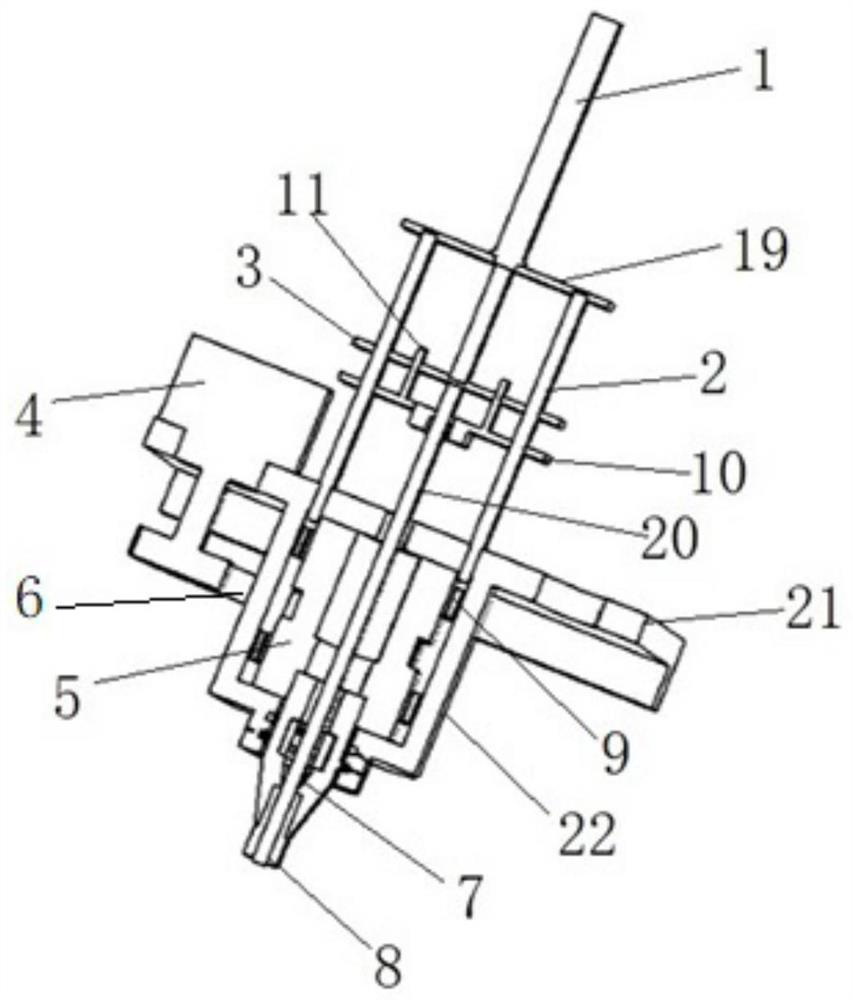

[0035] like Figure 1-4 As shown, this embodiment provides a laser-assisted friction stir additive welding tool, including,

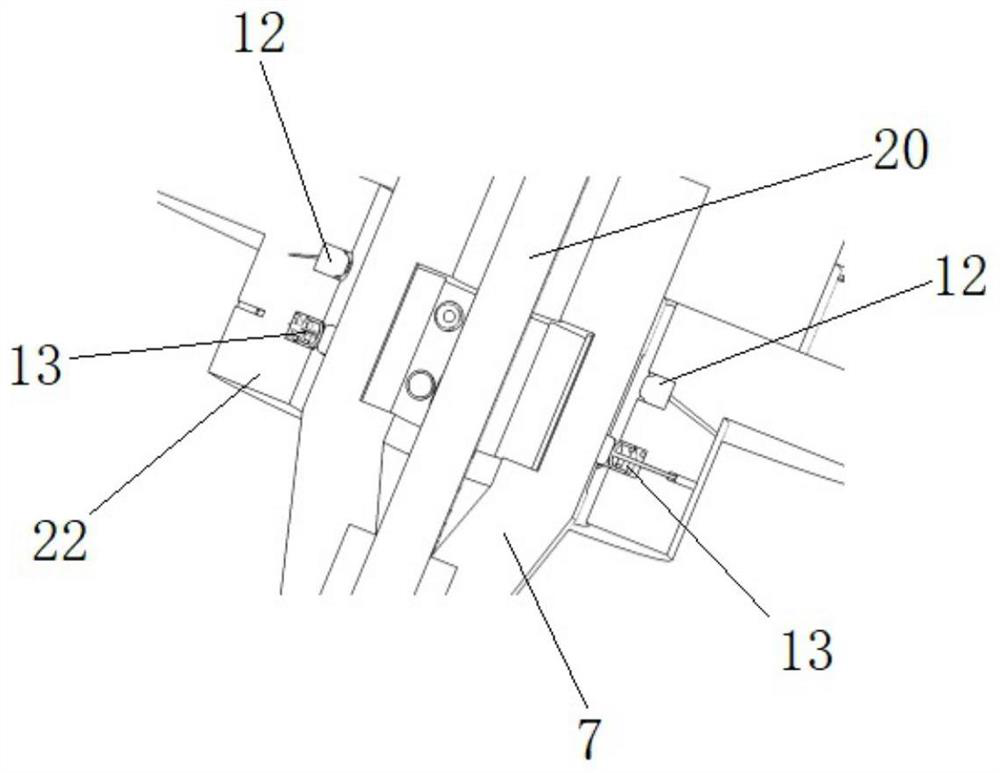

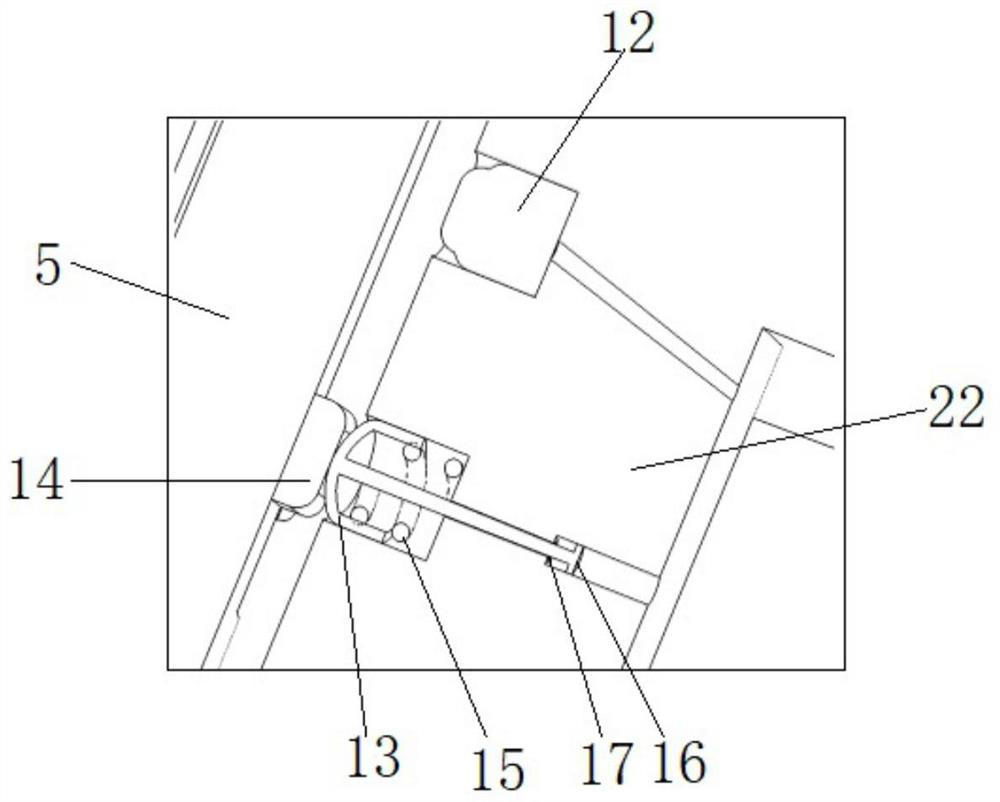

[0036] The handle 7, the side wall of the handle 7 is separated from the laser channel 18, and the side wall of the handle 7 between two adjacent laser channels 8 is a frame structure 23;

[0037] Housing 22, which has a cavity suitable for passing through the knife handle 7; the knife handle 7 is arranged in the housing 22 in a manner of clearance fit with the housing; the housing 22 has Laser head 12 and push switch, described push switch is electrically connected with described laser head 12; Wherein, described knife handle 7 is adapted to be rotated relative to described housing 22 under the drive of main shaft 5, during rotation, all A part of the frame structure 23 is adapted to abut against the push switch, thereby closing the laser head 12; when the frame structure 23 breaks away from the push switch, the laser head 12 emits laser light, thereb...

Embodiment 2

[0046] like figure 1 As shown, this embodiment also provides a laser-assisted friction stir additive welding device, which adopts the laser-assisted friction stir additive welding tool described in Embodiment 1, and further includes a base 21, the base 21 and the shell The body 22 is connected; the side wall of the housing 22 is provided with a transmission hole, and the base outside the housing is provided with a motor 4, and the driving belt of the motor 4 is transmitted through the transmission hole and the main shaft 4 of the welding tool. connection, specifically, the drive belt can be selected as a belt 6, and the motor 4 drives the main shaft 5 to rotate through the belt 6 to provide power for friction stir welding.

[0047] Optionally, the above-mentioned laser-assisted friction stir additive welding device also includes an additive conveying structure, which includes a guide bracket, and the guide bracket includes an upper plate 19 and a linear drive structure 1 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com