Large oil cylinder assembling device

A technology for assembling equipment and oil cylinders, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low installation efficiency and slow moving speed of end caps, and achieve fast and sensitive length control, easy processing, and shortened horizontal operation. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further detailed explanation through specific implementation mode below:

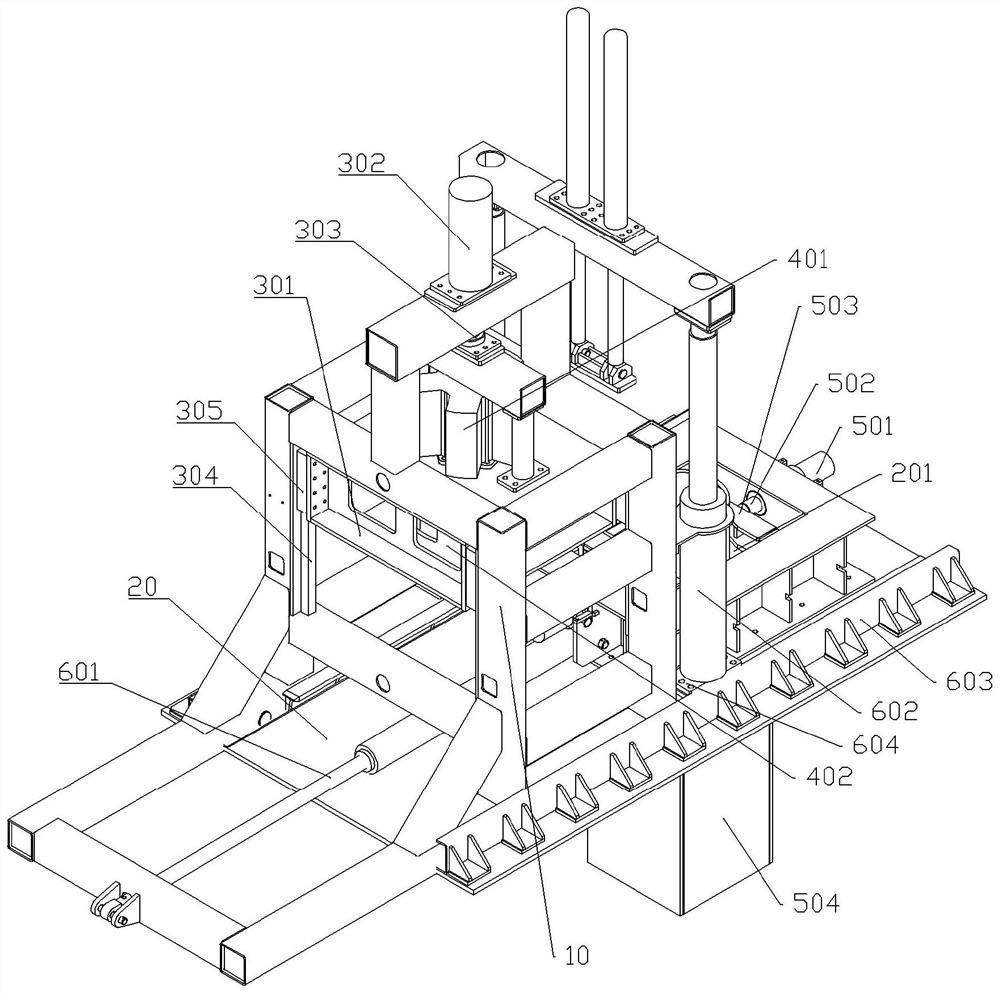

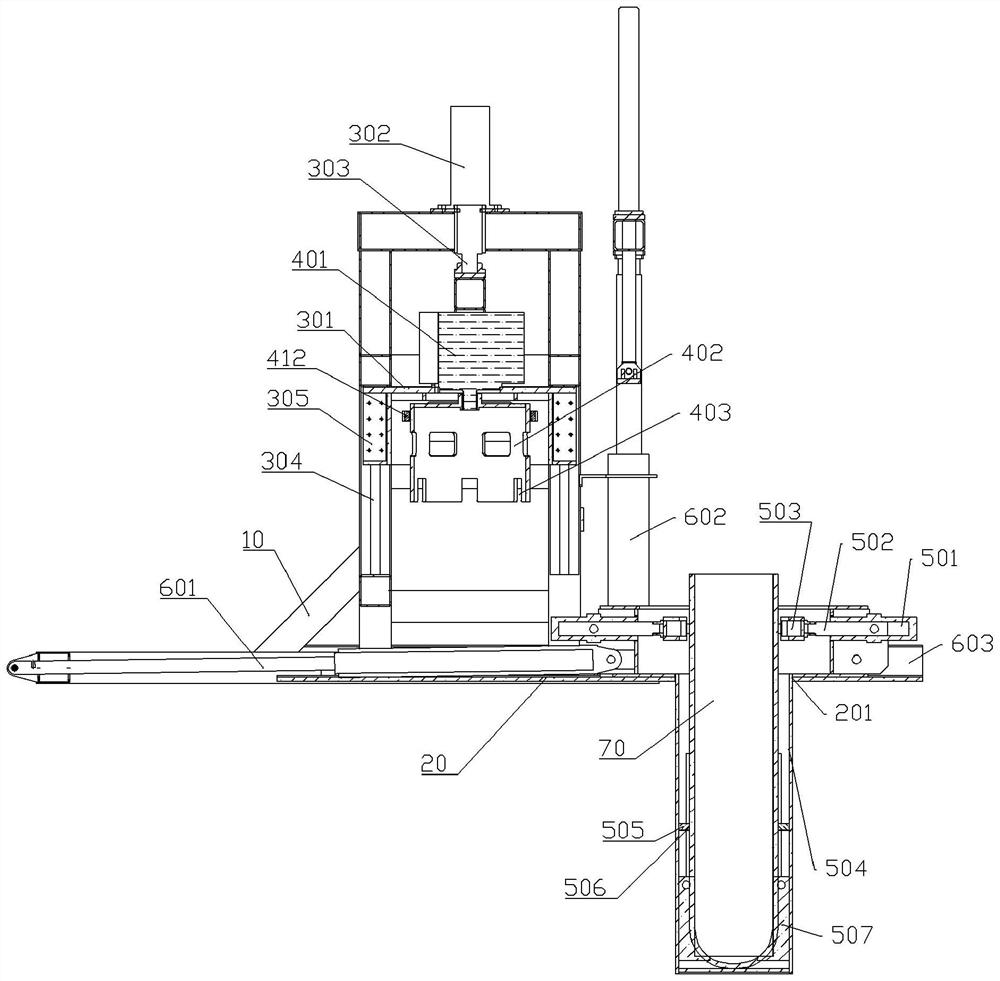

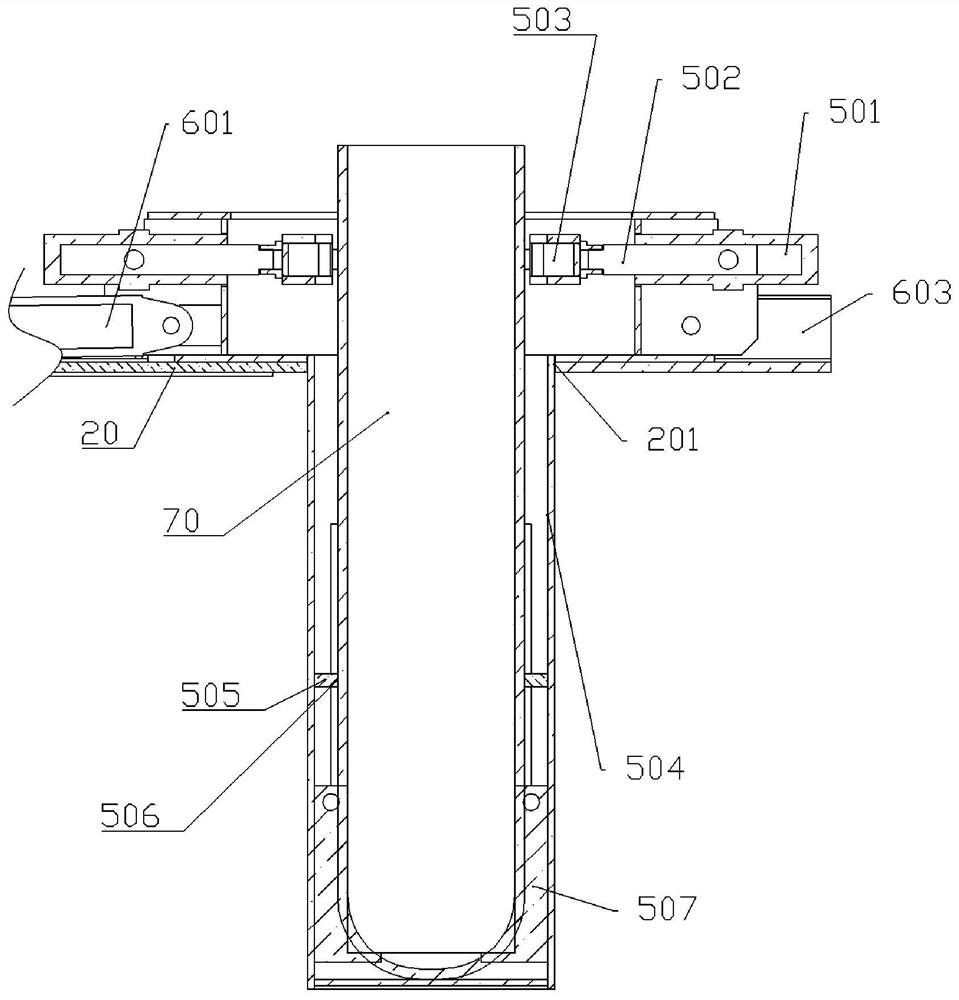

[0032] The reference signs in the drawings of the description include: frame 10, processing table 20, installation hole 201, lifting group frame 301, lifting cylinder 302, second telescopic rod 303, second guide rail 304, second slider 305, first Hydraulic motor 401, swivel head 402, card slot 403, cylinder removal telescopic rod 405, support block 406, second hydraulic motor 407, tight groove 408, upper support block 409, lower support block 410, fixed sleeve 411, ratchet 412, Worktable oil cylinder 501, clamping piston rod 502, limit block 503, fixed cylinder 504, mounting plate 505, through hole 506, support frame 507, first telescopic rod 601, pressing oil cylinder 602, first slide rail 603, second A slider 604 and the housing 70.

[0033] The embodiment is basically as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4Shown: a large-scale oil cylinder asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com