Intelligent grabbing mechanical arm used in cooperation with conveying line

A technology of robotic arms and conveyor lines, applied in the direction of robotic arms, program-controlled robotic arms, manufacturing tools, etc., which can solve problems such as high cost, cooperative use, and wear of internal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

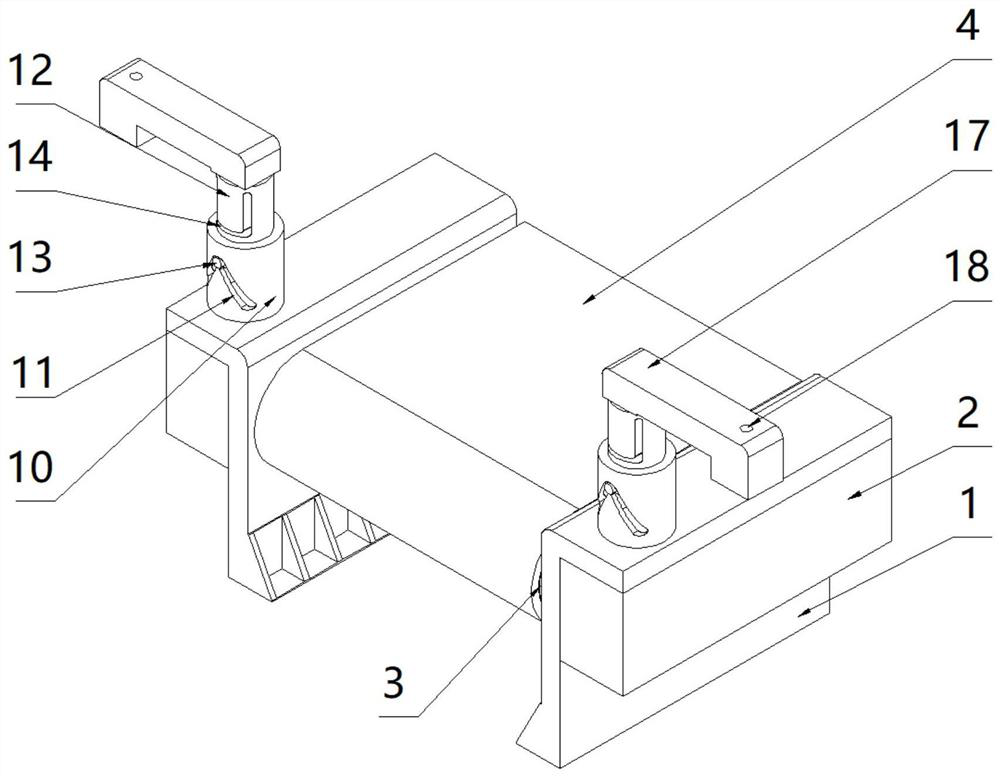

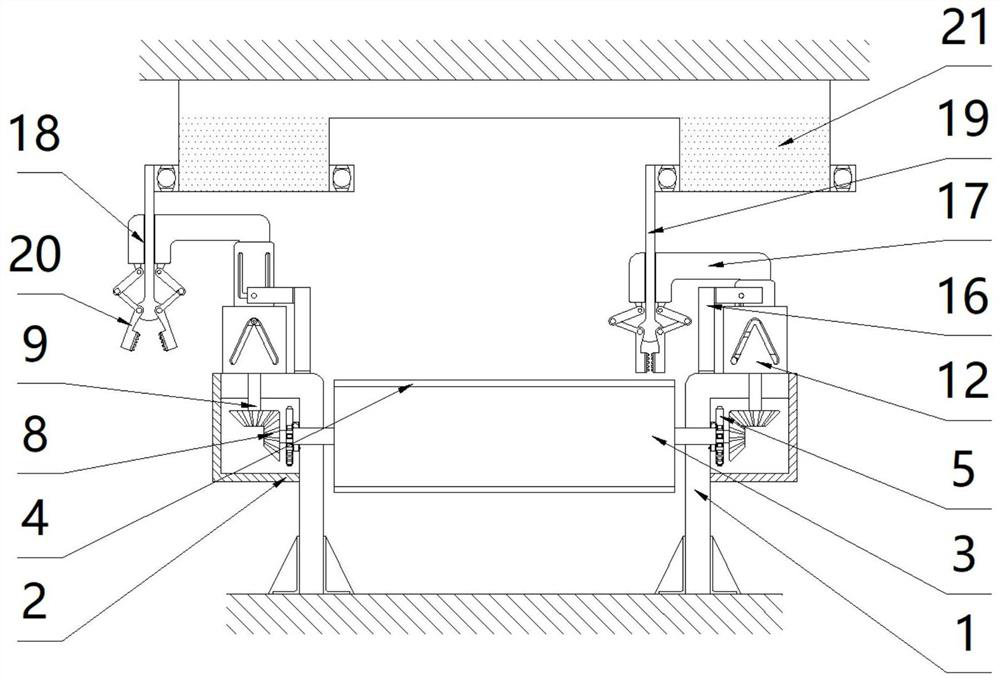

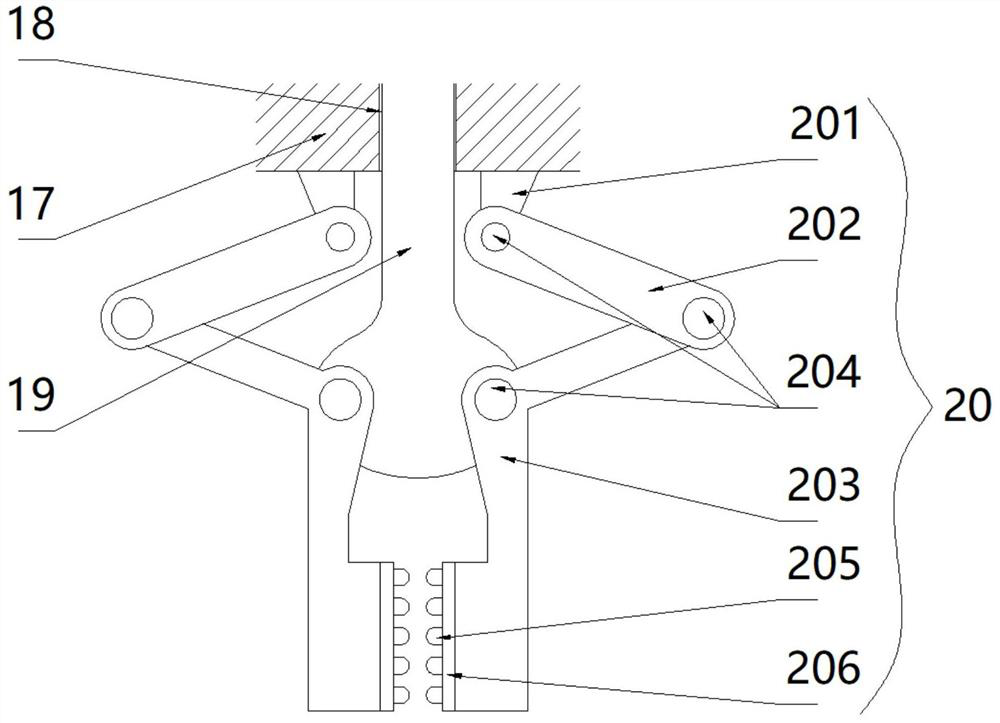

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0045] At present, the conveying line and the grabbing robot arm are two separate areas. In the process of use, each has its own separate function to cooperate with each other. There are many transmission components that need to be used, and the rotation of the conveying roller cannot be well utilized. Driving the mechanical arm to perform a series of operations requires additional transmission components to control the mechanical arm, which increases the cost of device production and is also not conducive to PCBA testing.

[0046] Moreover, during the detection process, the transmission parts will be subject to greater wear and tear, which will affect the service life of the device. To this end, the inventor propose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com