Section steel rim and wheel

A technology of wheel rim and section steel, which is applied to wheels, rims, spoked wheels, etc., can solve problems such as failure to ensure mutual restraint between wheel and tire assemblies, failure to meet the needs of heavy-load trucks, vehicle safety problems, etc., to improve convenience. , Reduce the failure rate and production cost, the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

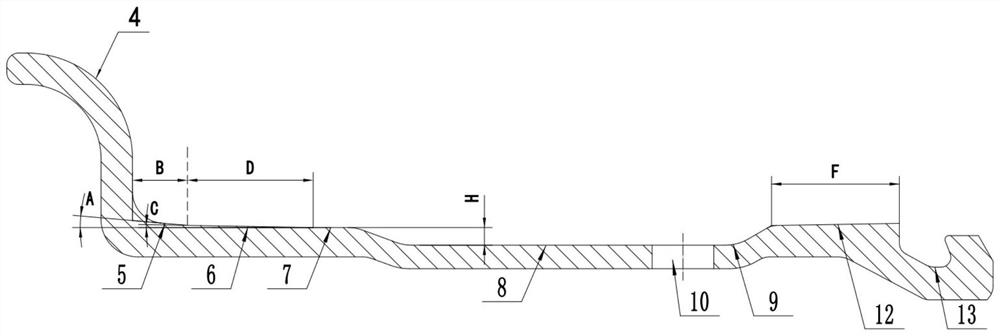

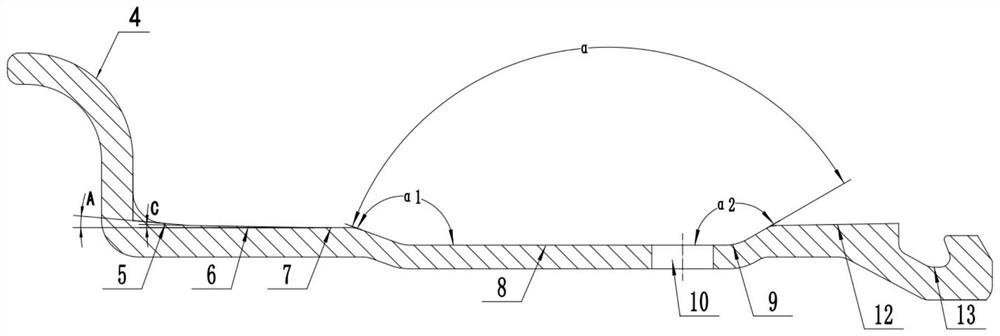

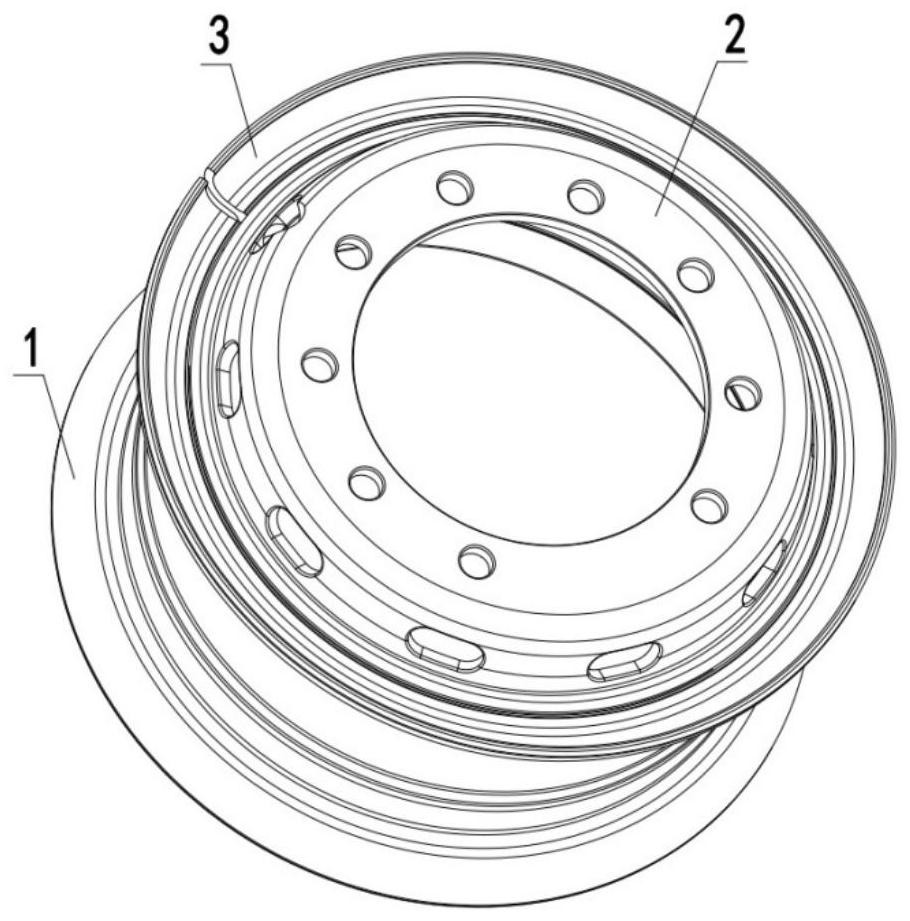

[0047] Such as Figure 1 to Figure 5As shown, a steel wheel rim includes a rim main body 1, one side of the rim main body 1 is provided with a fixed rim 4, and the other side is provided with a locking ring groove 13, and the connection between the fixed rim 4 and the locking ring groove 13 is The rim main body 1 in between is provided with a bottom groove 8, and the rim main body 1 between the fixed rim 4 and the bottom groove 8 is provided with a first bead seat 5 and a second bead seat 6, and the lock ring groove The third bead seat 12 is provided on the rim body 1 between 13 and the bottom groove 8, and the angle A between the first bead seat 5 and the axis of the rim body 1 is larger than that between the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle a | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com