Concrete sewage recovery treatment system and method

A technology of sewage recovery and treatment system, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing sand and gravel content, reducing cleaning costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

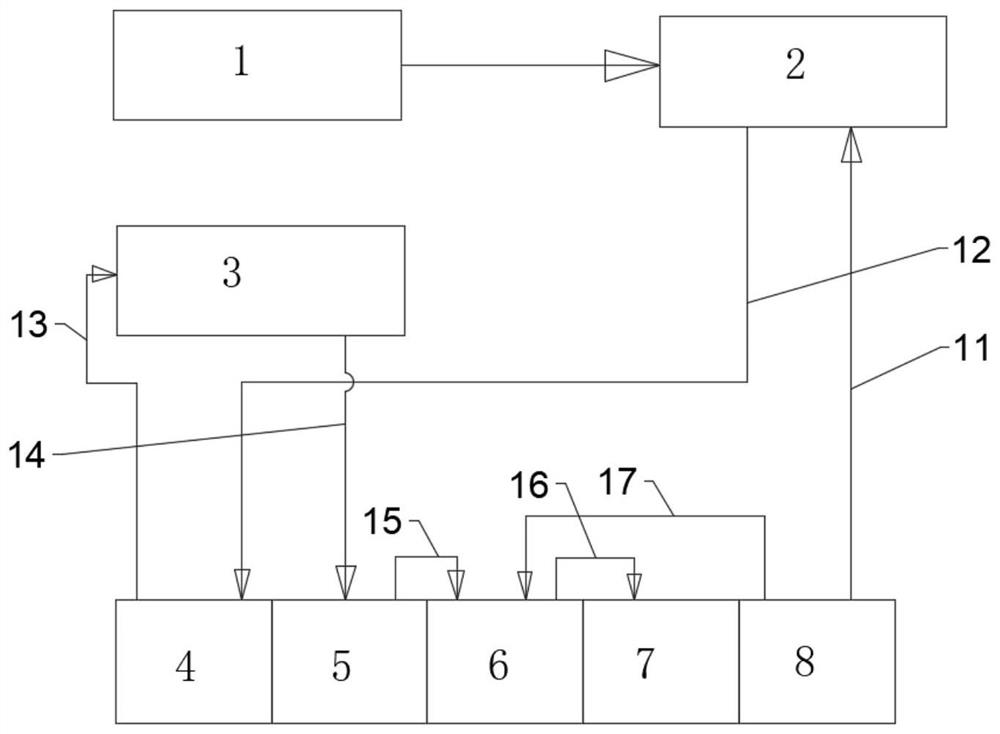

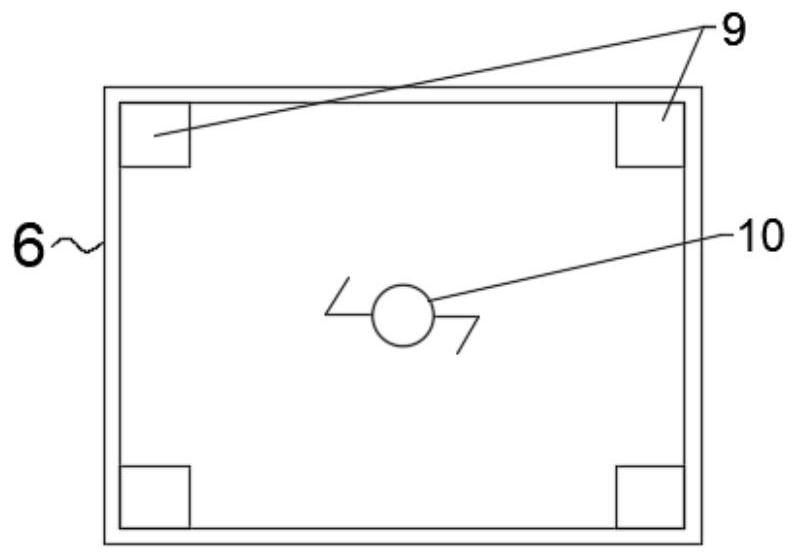

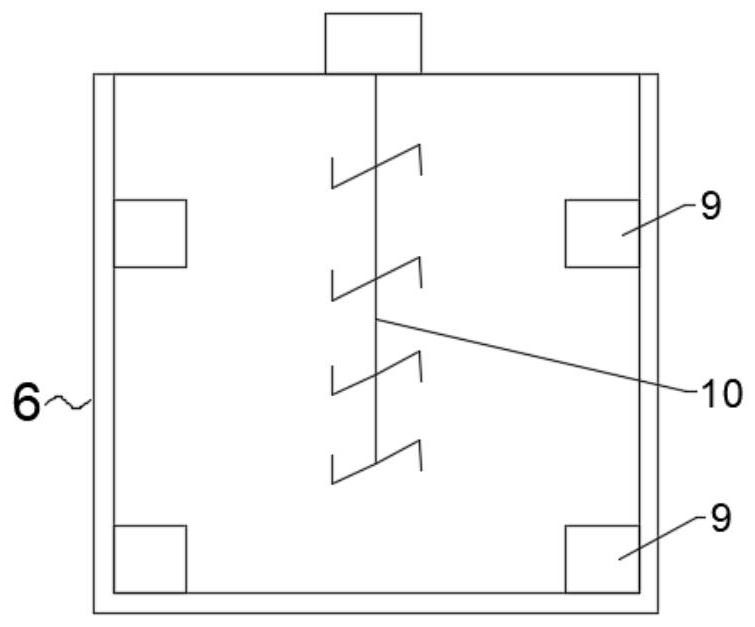

[0052] to combine Figure 1-4 As shown, a concrete sewage recovery and treatment system is disclosed in Embodiment 1, including a sandstone loading mechanism 1, a sandstone separation mechanism 2, a fine sand recovery mechanism 3, a sewage deployment mechanism 9 and a plurality of pools, wherein the The pool body includes a sewage tank, a deployment tank 6, a finished product tank 7 and a clarification tank 8, and the clarification tank 8 injects clear water into the deployment tank 6 and the sand and gravel separation mechanism 2 respectively through pipelines, and the sand and gravel separation mechanism 2 and the fine sand The recovery mechanism 3 discharges sewage into the sewage pool through pipelines, and the finished product pool 7 is used to store the prepared sewage. In addition, the sewage pool, the deployment pool 6 and the finished product pool 7 are all equipped with a stirring mechanism 10, and the stirring The mechanism 10 is used to prevent precipitation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com