Annular double-chamber lime kiln spray gun adjusting method

The technology of a double-chamber lime kiln and an adjustment method is applied in the direction of lime production, which can solve the problems of uneven calcination and inability to guarantee the quality of lime, and achieve the effect of reducing the analysis range, ensuring the quality, and improving the adjustment speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

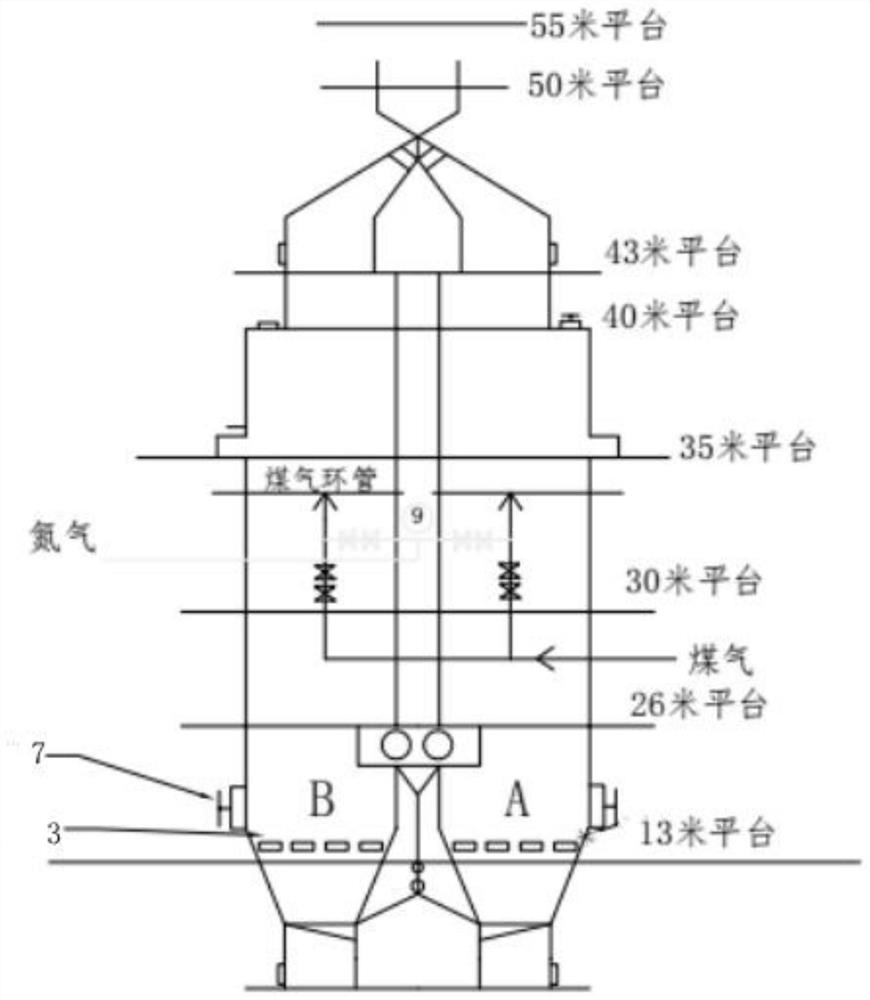

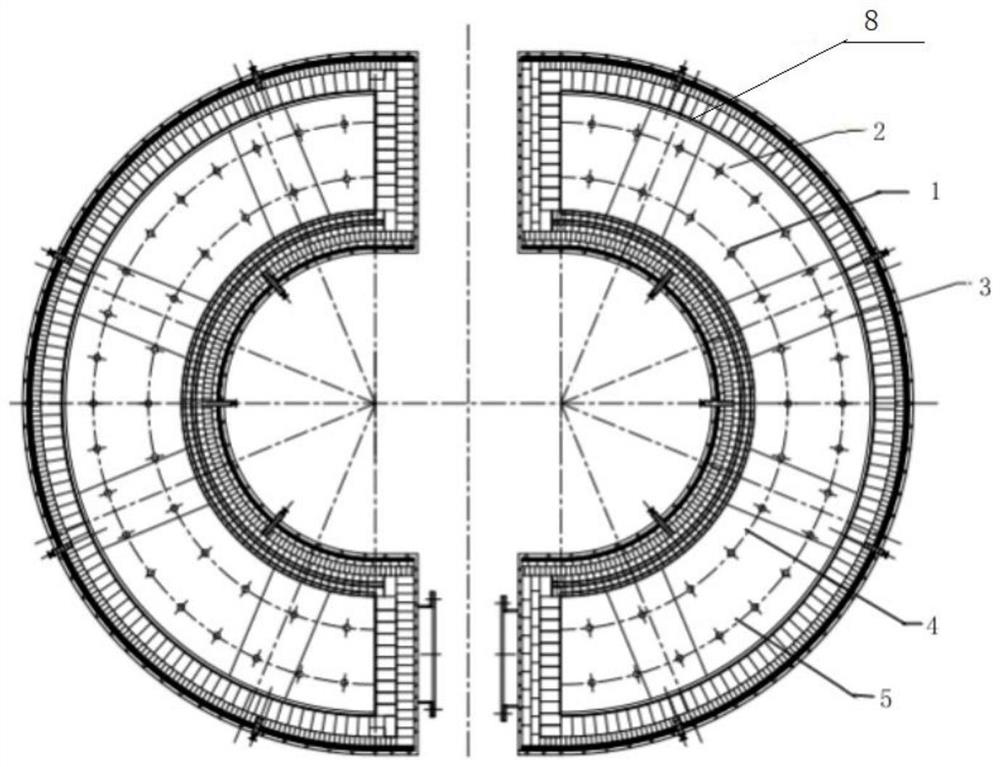

[0032] like figure 2 According to the plan view of the kiln body, it can be seen that the lime kiln has 35 meters of lances, 13 lances in the inner ring and 19 lances in the outer ring, which are evenly distributed in the lime kiln. The function of the lances is to provide fuel to the lime kiln. . There are four push valves at the bottom of each kiln.

[0033] Adjust the spray gun of the annular double-chamber lime kiln as follows:

[0034] 1) Open all spray guns at a uniform angle of 70°;

[0035] 2) According to the vertical position of the spray gun, according to the principle of proximity, all spray guns are corresponding to the push valve;

[0036] 3) The lime falls into the push valve, and takes samples from each push valve through the manhole:

[0037] 4) According to the state of the sampled lime, adjust the angle of the spray gun corresponding to the push valve. If it is slaked lime, it will not change; if it is quick lime, adjust the angle of the spray gun corr...

Embodiment 2

[0039] Adjust the spray gun of the annular double-chamber lime kiln as follows:

[0040] 1) Open all spray guns at a uniform angle of 70°;

[0041] 2) According to the vertical position of the spray gun, according to the principle of proximity, all spray guns are corresponding to the push valve;

[0042] 3) The lime falls into the push valve, and takes samples from each push valve through the manhole;

[0043] 4) According to the state of the sampled lime, adjust the angle of the spray gun corresponding to the push valve. If it is slaked lime, it will not change; if it is quick lime, adjust the angle of the spray gun corresponding to the sampling point to be greater than 70°.

[0044] 5) After adjustment, re-sampling to judge and adjust until the lime is qualified.

Embodiment 3

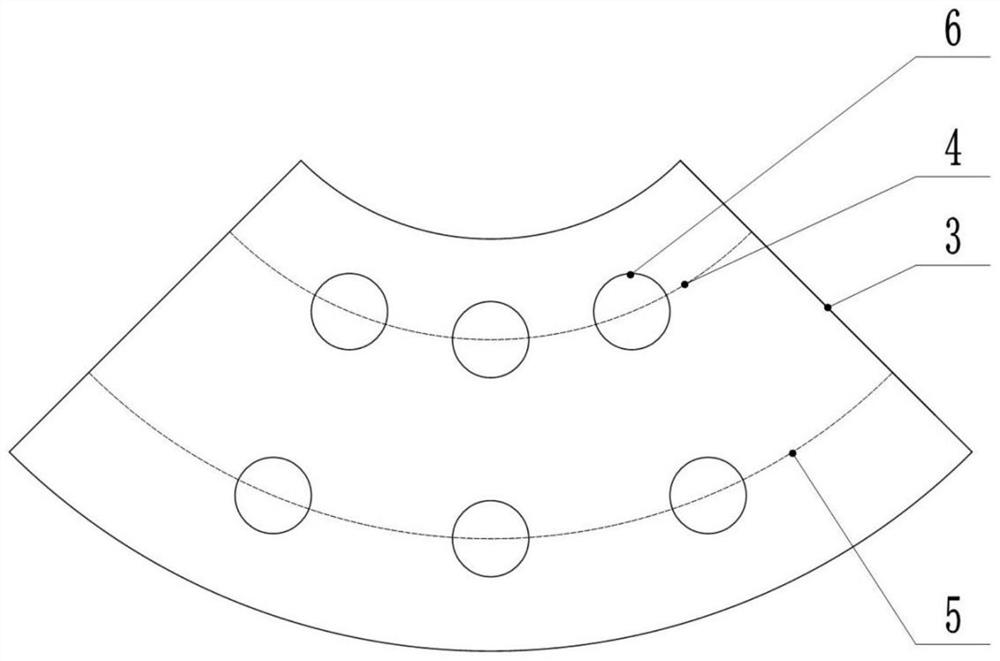

[0046] On the basis of implementing 2-3, the method for determining the sampling point in the push valve is as follows:

[0047] 3.1) Determine the projection arc of the corresponding inner ring spray gun and the corresponding outer ring spray gun in the push valve, and the center of the circle is the geometric center of the push valve: according to the direction of the falling of lime.

[0048] The radius of the projected arc of the inner ring spray gun R1=Rn*Lt / R, where Rn is the radius of the circle where the inner ring spray gun is located, Lt is the vertical distance from the outer edge of the push valve to the center line of the furnace, and R is the radius of the furnace;

[0049] The radius of the projection arc of the outer ring spray gun R2=Rw*Lt / R, where Rw is the radius of the circumference of the outer ring spray gun, Lt is the vertical distance from the outer edge of the push valve to the center line of the furnace, and R is the radius of the furnace;

[0050] 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com