Hydraulic direct pushing type refining mud machine and method thereof

A kind of mud training machine and direct push technology, which is applied in the direction of chemical instruments and methods, clay preparation equipment, clay processing equipment, etc., which can solve the problems of insufficient extrusion power, sticking to a certain point in the inner chamber, and mud compactness. Inhomogeneity and other problems can be achieved to achieve uniform performance, save operating time, and the inner wall is bright and smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

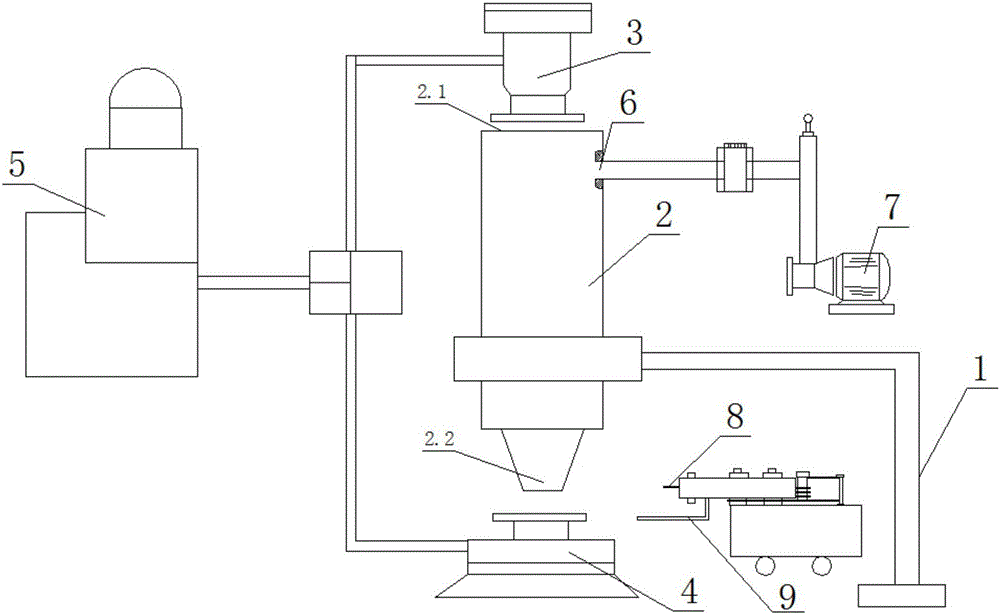

[0031] as attached figure 2 As shown, a kind of hydraulic direct-pushing mud refining machine of the present invention comprises frame 1, and vertical mud refining machine cylinder body 2 is fixed on the frame 1, and the upper end of vertical mud refining machine cylinder body is mud inlet 2.1 , the lower end is the mud outlet 2.2; the first hydraulic piston 3 is arranged above the cylinder of the vertical mud refining machine, and the second hydraulic piston 4 is arranged below the cylinder of the vertical mud refining machine. The first hydraulic piston and the second hydraulic piston The hydraulic piston realizes reciprocating motion through the oil pump 5 (an oil delivery pipeline is arranged between the first hydraulic piston and the second hydraulic piston and the oil pump); the outer contour of the first hydraulic piston matches the inner wall of the vertical mud refining machine cylinder , the outer contour of the second hydraulic piston is larger than the mud materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com