A leaf spring vibration hydraulic power generation system

A technology of hydraulic power generation and leaf spring, applied in the direction of collectors, electric vehicles, electrical components, etc., can solve the problems of reduced effective power output, short cruising range, affecting popularization and application, etc., to avoid the waste of electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings.

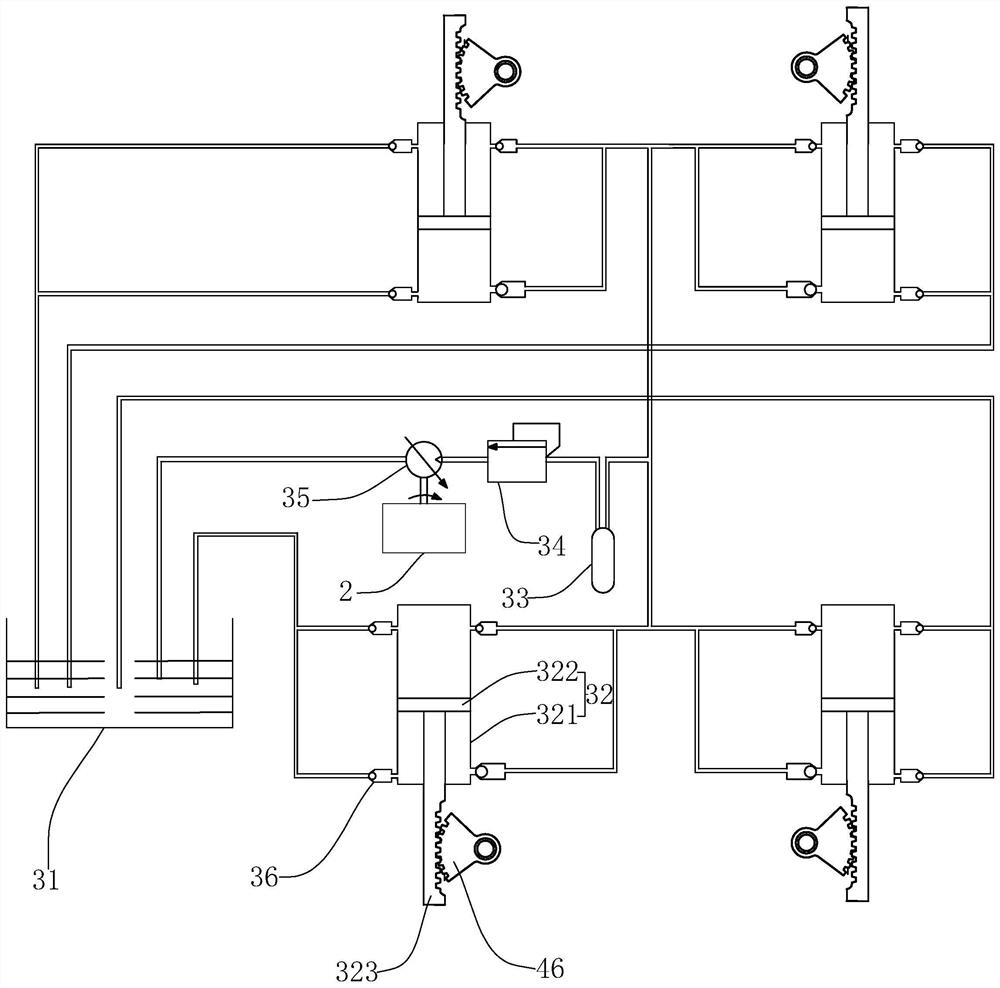

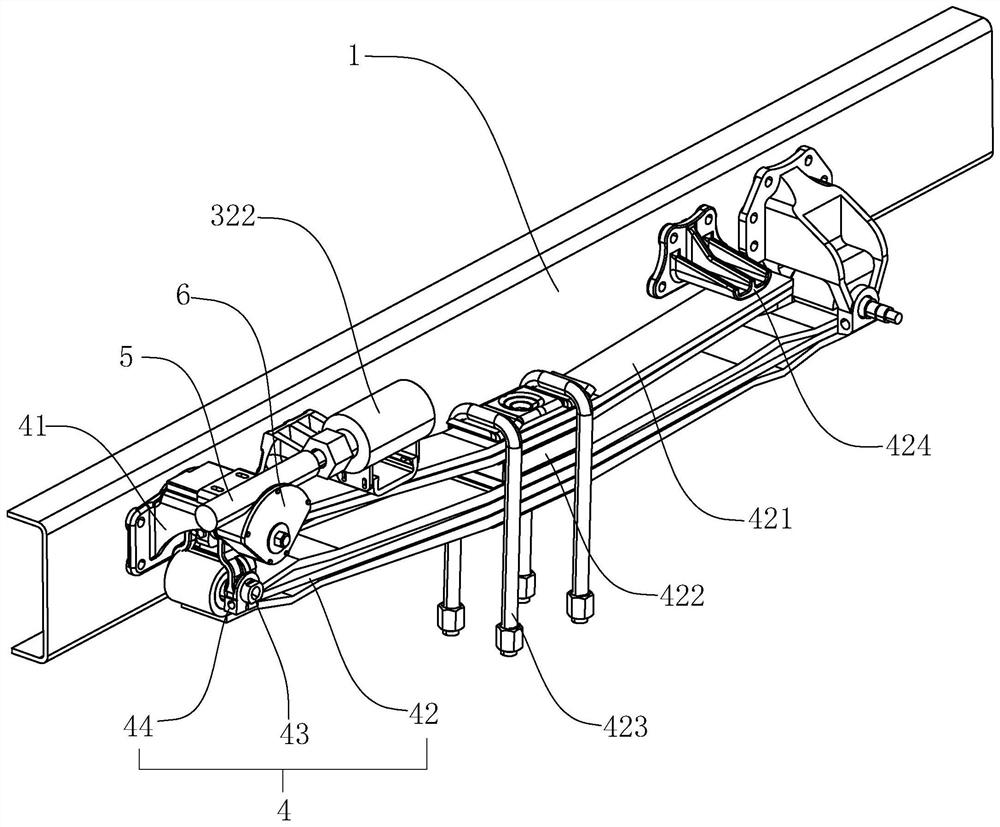

[0029] like figure 1 As shown, a leaf spring vibration hydraulic power generation system includes a generator 2, a power unit 4 that provides power, and a transmission unit that transmits power and converts it into torque, wherein the generator 2 includes a rotor and a battery that forms an excitation magnetic field. 4 and the transmission unit make the rotor of the generator 2 rotate, and the rotor cuts the excitation magnetic field formed by the battery. When the rotor speed gradually increases until the voltage of the generator 2 is higher than that of the battery, the generator 2 charges the battery in reverse, and provides other The electrical device provides electrical energy.

[0030] like figure 1 As shown in the figure, the transmission unit includes an oil tank 31, a hydraulic cylinder 32 and a hydraulic motor 35 which are connected in sequence alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com