Variable cross-section hydraulic bidirectional buffer device applied to air flow regulation of reciprocating compressor

A technology of air volume adjustment and two-way buffering, which is applied in the direction of fluid pressure actuators, liquid variable capacity machines, mechanical equipment, etc. It can solve the problems of large impact of the air valve and low control precision of the buffer structure, so as to prolong the service life and shorten the The effect of technology gap and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

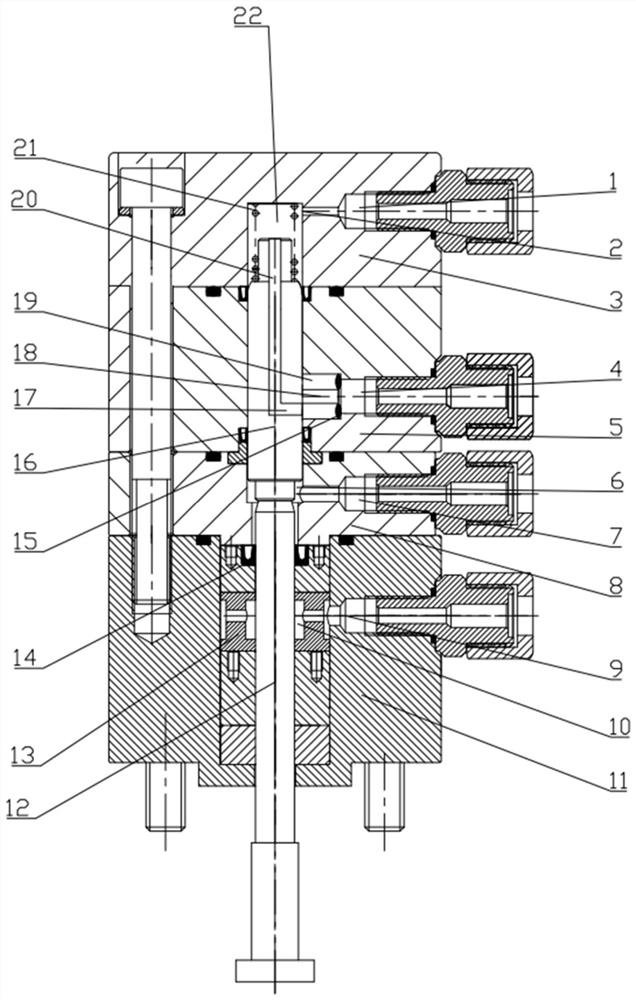

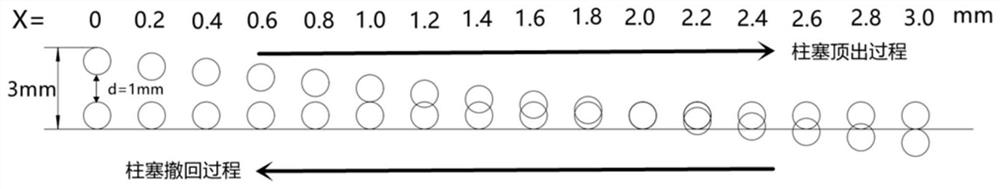

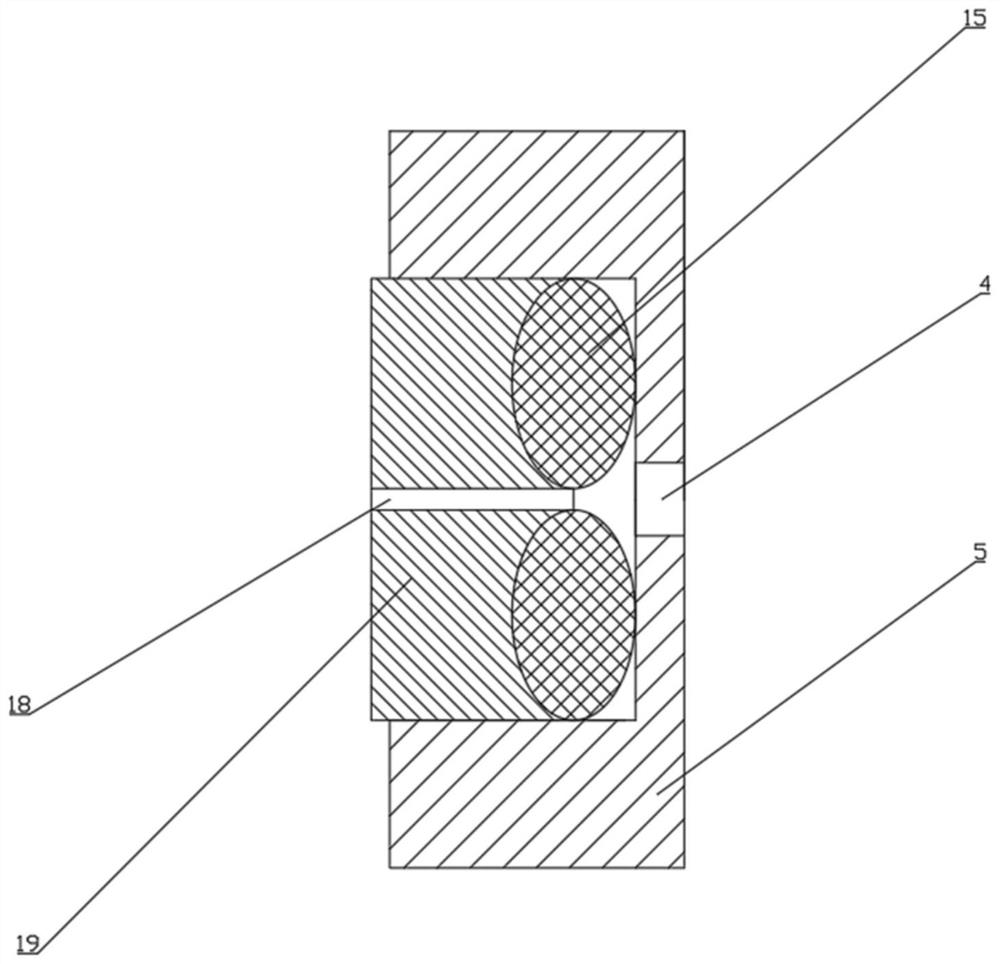

[0104] Such as figure 1 As shown, it is a schematic diagram of the oil cylinder structure, including the first cylinder body 3, the second cylinder body 5, the third cylinder body 8, the fourth cylinder body 11, the ejector rod 12, the plunger 16, the buffer spring 21, and the lip seal ring 14. The double triangle slip ring 19 and the O-ring 15 together form a double triangle ring combined seal, the hydraulic oil enters the hydraulic oil working chamber 22 through the oil inlet 1 through the oil inlet orifice 2 to push the plunger 16 and the ejector rod 12 Moving along its central axis, the oil leakage port 7, the air leakage port 9, and the oil leakage port 4 communicate with the oil leakage recovery cavity 6, the leakage gas recovery cavity 10 and the oil leakage orifice 18 respectively, and the top of the buffer spring 21 is against the Connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com