Method and structure for preventing internal leakage of manual temperature adjusting water mixing valve

A water mixing valve and temperature regulation technology, applied in multi-way valves, balance valves, valve devices, etc., can solve the problems of long internal leakage, sealing failure of the mixing valve, blockage of the nozzle filter, etc., and achieves broad market prospects. High promotion value, reliable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

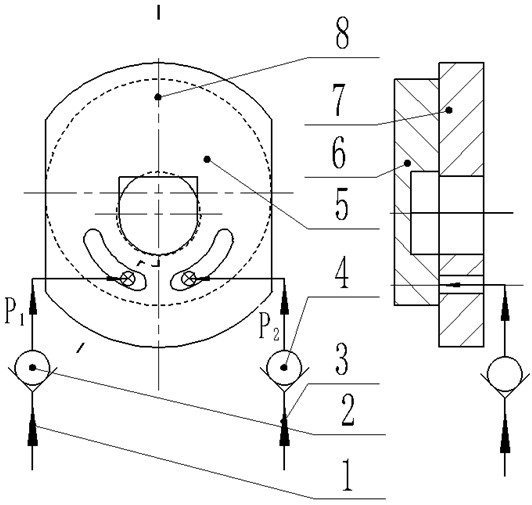

[0021] 1. Structure and connection

[0022] Such as figure 1 As shown, a method for preventing internal leakage of a manual temperature-adjusting water mixing valve disclosed by the present invention is: using the check feature of the one-way valve to prevent external water of different temperatures from entering the interior of the pipeline. Structure and connection: Install a one-way valve between the cold and hot water pipes and the cold and hot water inlets of the manual temperature-adjusting mixing valve according to the water supply direction (that is, the direction of the one-way valve is consistent with the water supply direction). The one-way valve described above is integrated with the manual temperature-regulating water-mixing valve into an anti-endleakage manual temperature-regulating water-mixing valve.

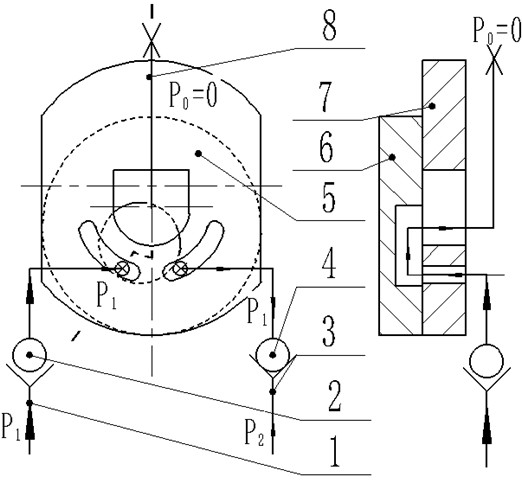

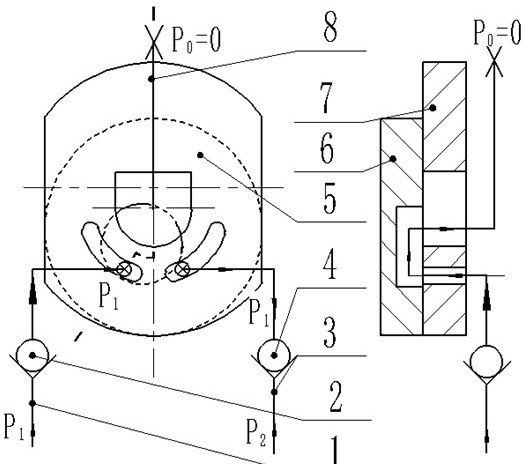

[0023] Two, structural work of the present invention and anti-endal leakage analysis

[0024] 1. When the water mixing valve 5 is opened, the shut-off valve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com