Light source module and ceiling lamp

A technology of light source module and light source board, applied in the field of LED lighting, can solve the problems of unreasonable structure of light source module, dark spots of ceiling lamps, affecting user experience and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

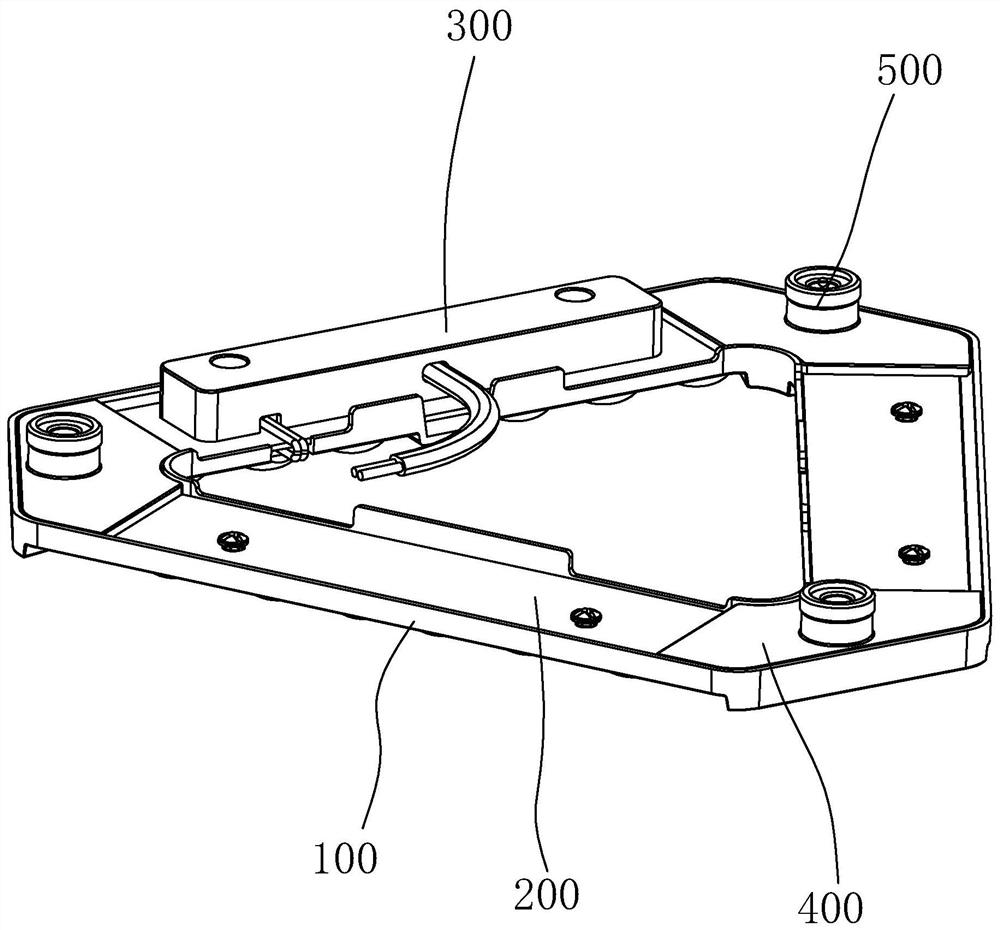

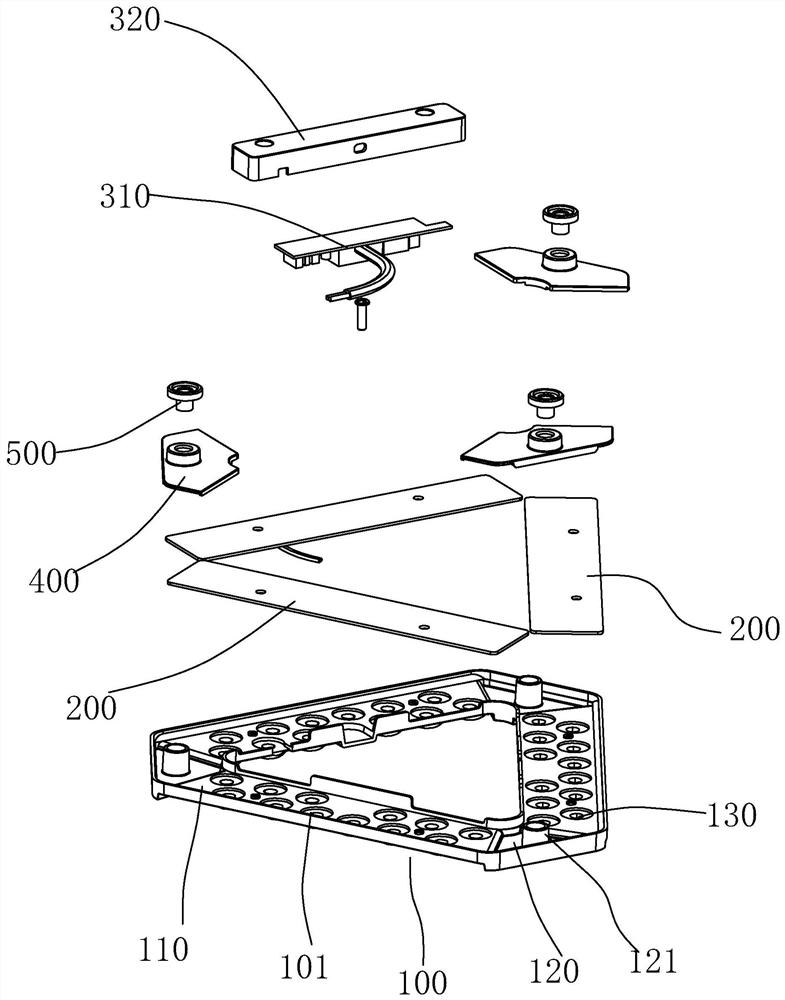

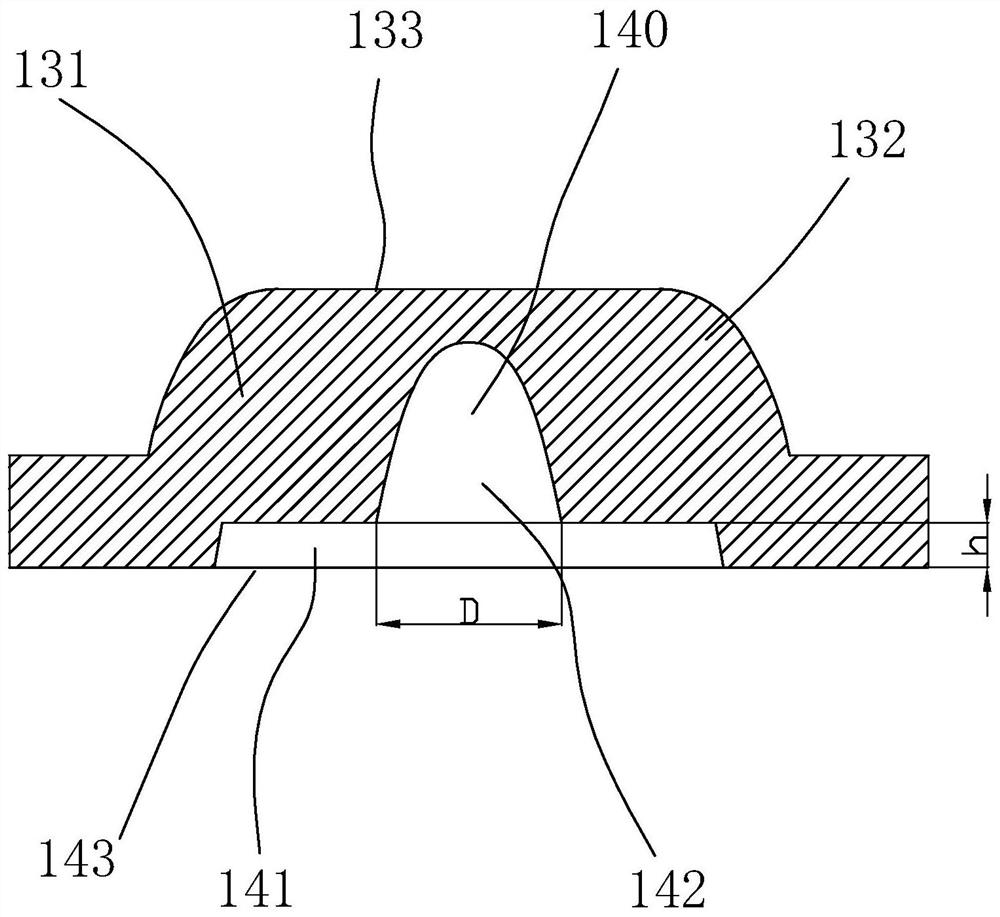

[0030] Embodiment one, with reference to Figure 1 ~ Figure 3 , a light source module, including a lens 100, a light source board 200, a power supply assembly 300, and a magnet seat 400, the lens 100 is roughly triangular in shape, the middle of the lens 100 is hollow, and the lens 100 includes a light source installation cavity 110 and Magnet installation chamber 120, the lens 100 is provided with ribs 101 around the light source installation chamber 110, there are three light source installation chambers 110 and three magnet installation chambers 120, three light source boards 200, three light source boards The board 200 is respectively installed in three light source installation cavities 110, the front of the light source board 200 is provided with a plurality of lamp beads, and the light source installation chamber 110 is provided with a plurality of lens units 130, and the lamp beads and The lens units 130 correspond one-to-one; there are three magnet mounts 400, and the...

Embodiment 2

[0039] Embodiment two, see Figure 5 , Figure 6 , a light source module. The light source module of this embodiment has a similar lens unit 130 structure to that of Embodiment 1, but the shape of lens 100 is different from that of Embodiment 1. In Embodiment 2, the lens 100 as a whole is Square, the middle of the lens 100 is also hollowed out, and the back of the lens 100 is provided with a ring-shaped light source plate 200 . In this embodiment, the back of the lens 100 does not need to be provided with a magnet seat installation cavity, the magnet seat 400 is directly bonded to the back of the light source board 200 , and the power supply assembly 300 is also directly bonded to the back of the light source board 200 .

[0040] Different from Embodiment 1, the snap connection between the light source board 200 and the lens 100 is completed through the clamping post 150. Specifically, the light source board 200 is provided with a clamping hole 210, and the clamping post 150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com