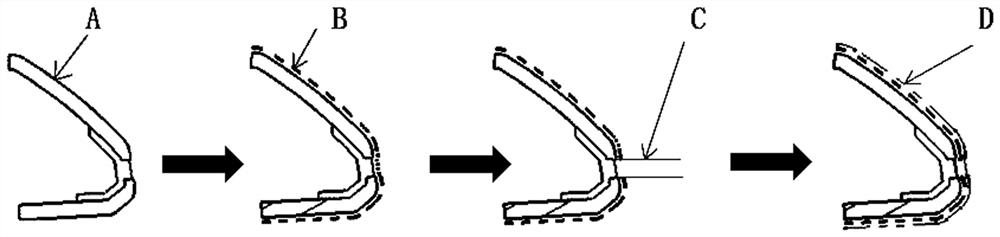

Production process of multicolor exterior lamp mask

A production process and mask technology, which is applied in the field of multi-color exterior lamp mask production technology, can solve the problems that the lamp mask production process cannot be realized, achieve the effect of increasing appearance diversity and avoiding quality problems at seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Embodiment: Step 1: First, use PC or PC+diffusion agent material to inject the light-transmitting part in the mold. After the light-transmitting part is formed, then use ABS or PC+ABS to inject the opaque part to complete the molding of the mask body. During the process: drying material temperature: 110℃~120℃.

[0032] Baking time: 3 to 4 hours.

[0033] Moisture content: ≤0.02%.

[0034] Mold temperature: 100-120°C.

[0035] Melting temperature: 270℃~330℃.

[0036] Injection pressure: 80MPA ~ 150MPA.

[0037] For the treatment of PC+ABS materials: Baking material temperature: 100℃~105℃.

[0038] Baking time: 3 to 4 hours.

[0039] Moisture content: ≤0.02%.

[0040] Mold temperature: 70-90°C.

[0041] Melting temperature: 230℃~270℃.

[0042] For the treatment of ABS materials: baking material temperature: 85 ℃ ~ 95 ℃.

[0043] Baking time: 3 to 4 hours.

[0044] Moisture content: ≤0.02%.

[0045] Mold temperature: 70-90°C.

[0046] Melting temperature: 220℃~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com