Novel TPO skin environment-friendly automobile soft instrument board and manufacturing process thereof

An instrument panel and environment-friendly technology, which is applied in the field of TPO skin environment-friendly automobile soft instrument panel and its manufacturing process, can solve the problems of bad smell, VOC volatility reduction, high concentration, etc., and achieve TVOC reduction, odor reduction, VOC volatilization and odor performance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

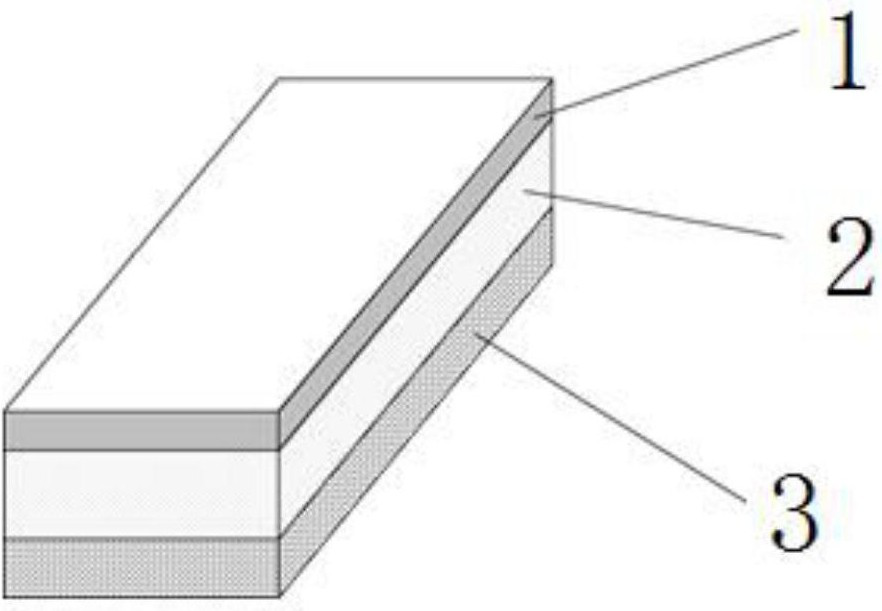

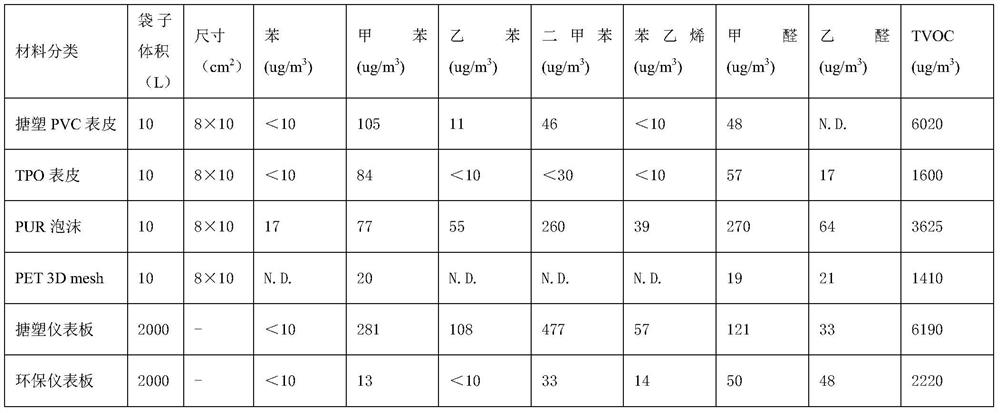

[0028] Such as figure 1 As shown, a new TPO-skin environment-friendly automotive soft instrument panel, from the inside to the outside is a skeleton layer, a middle buffer layer and a skin layer; the skeleton layer is a glass fiber reinforced PP material, and the middle buffer layer is a three-dimensional net PET 3D mesh material with porous structure, the skin layer is TPO material with base cloth.

[0029] The instrument panel skin material: TPO skin with low VOC volatilization and low odor of water-based polyurethane surface coating.

[0030] The middle buffer layer material of the instrument panel: PET 3D mesh material with three-dimensional mesh structure, thickness 3mm, surface density 240-300g / m 2 .

[0031] The material of the skeleton layer of the instrument panel: 30% glass fiber reinforced PP material.

[0032] The glue used in the process: environmentally friendly polyurethane water-based glue.

Embodiment 2

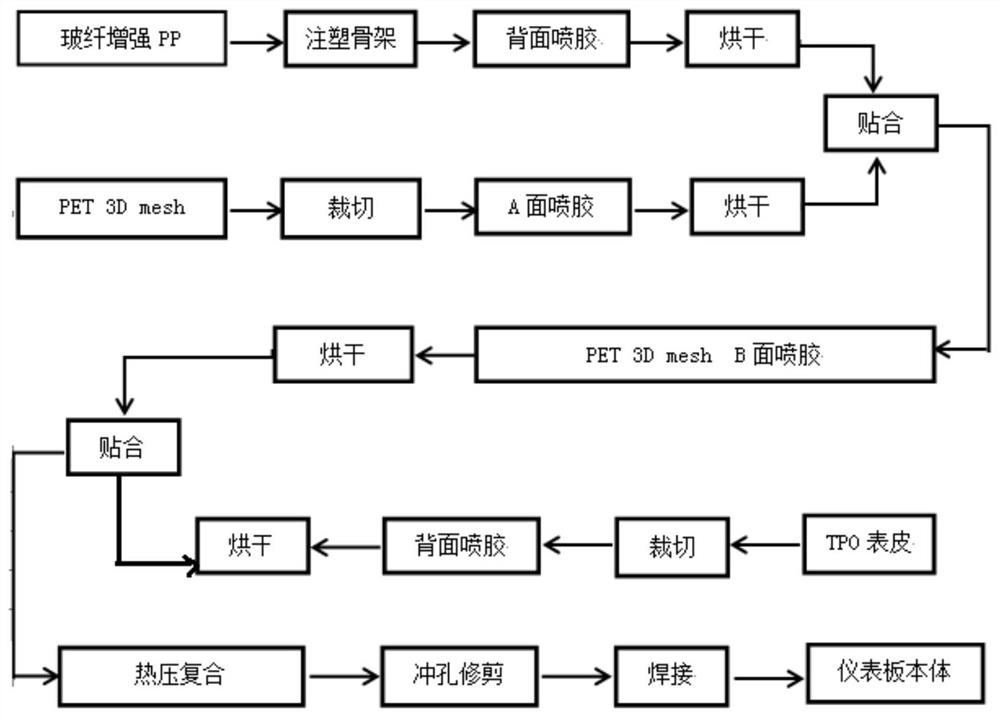

[0034] Such as figure 2 Shown, a kind of manufacturing process of new-style TPO skin environment-friendly automobile soft instrument panel, concrete steps are as follows:

[0035] 1) Dashboard skin layer: After cutting the TPO skin according to the required size of the dashboard and sewing it into a specified shape, spray environmentally friendly polyurethane water-based glue on the back base fabric, and the amount of glue sprayed is 40-80g; then put the TPO skin in the heating room Drying, heating temperature 60-80 ℃, heating time 15-30min;

[0036] 2) Dashboard buffer layer: PET 3D mesh material is cut into a specified shape, and the A side is sprayed with environmentally friendly polyurethane water-based glue, with a spray amount of 40-80g; then it is placed in a heating room for drying at a heating temperature of 60-80°C. Heating time 15-30min;

[0037] 3) Dashboard frame: Injection molding of glass fiber reinforced PP material, spray environmentally friendly polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com