Chip test equipment and test method applied to integrated circuit

A technology for integrated circuit and chip testing, applied in electronic circuit testing, measuring electricity, measuring devices, etc., can solve the problems of occupying a large space, reducing the operating space of workers, unable to simulate the performance of integrated circuit chips, etc., and achieving a reduced operating space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

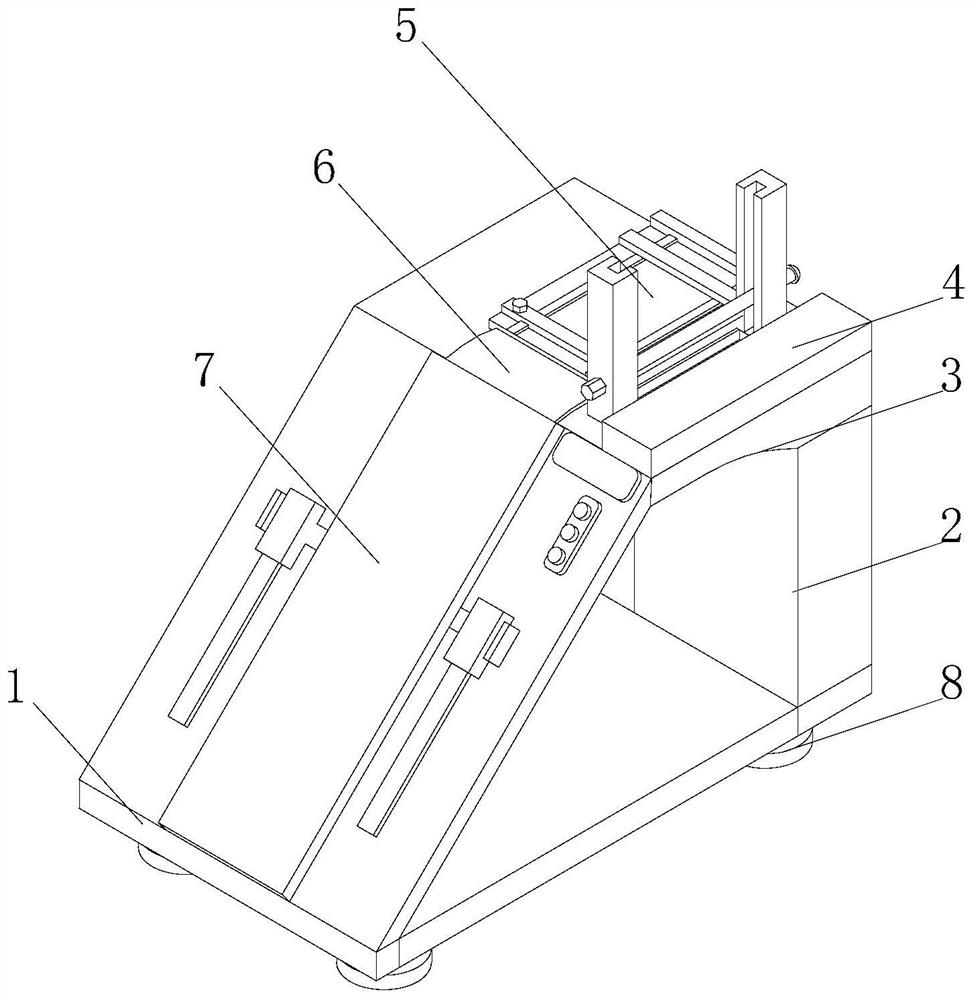

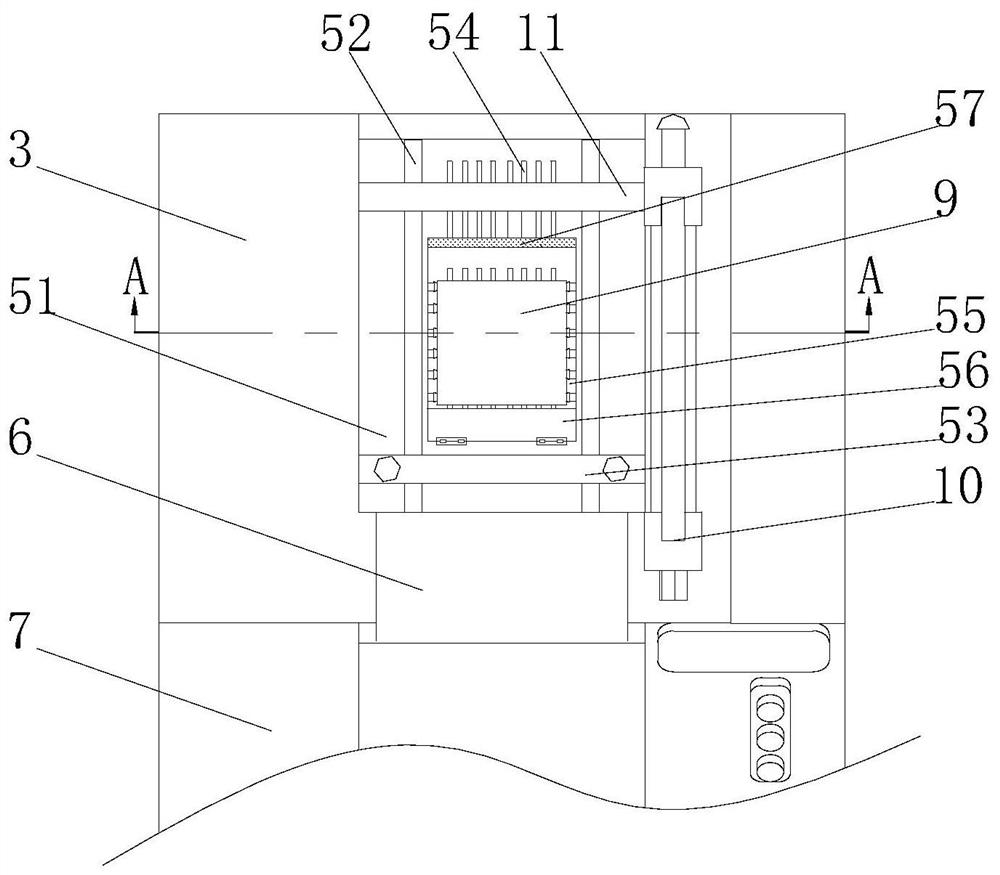

[0037] Such as Figure 1 to Figure 3 As shown, the present invention provides a technical solution: a chip testing device applied to integrated circuits, including a base 1, the top of the base 1 is fixedly connected with a power distribution cabinet 2, and the power distribution cabinet 2 is far away from the base 1 One side is fixedly connected with a fixed plate 3, and the side of the fixed plate 3 away from the power distribution cabinet 2 is fixedly connected with a central control mechanism 4, and the middle part of the side of the fixed plate 3 close to the central control mechanism 4 is fixedly connected with a chip simulation Drive mechanism 5, one end of the chip analog drive mechanism 5 is electrically connected to the operating device 7 through the transmission data line 6, the two ends of the operating device 7 are fixedly connected to the base 1 and the fixed plate 3 respectively, and the base 1 The four corners of the bottom are fixedly connected with supporting...

Embodiment 2

[0041] Such as Figure 3 to Figure 5 As shown, the present invention provides a technical solution on the basis of Embodiment 1: a chip testing device applied to integrated circuits, the fixing mechanism 553 includes a connecting shell b1, and one side of the connecting shell b1 slides A piston rod b2 is connected, and one end of the piston rod b2 inside the connection housing b1 is provided with a buffer device b3, and the end of the piston rod b2 away from the connection housing b1 is fixedly connected with a clamping device b4, and the connection housing The side of b1 close to the piston rod b2 is fixedly connected to the electromagnet b5, the side of the clamping device b4 close to the piston rod b2 is fixedly connected to the magnet block b6, and the side of the connection housing b1 away from the end of the piston rod b2 is connected. There is an air outlet b7, and the terminals of the electromagnet b5 are electrically connected to the central control mechanism 4 throug...

Embodiment 3

[0044] Such as Figure 4 to Figure 7 As shown, the present invention provides a technical solution on the basis of Embodiment 2: a chip testing device applied to integrated circuits, one end of the inner wall of the temperature detection device b44 is provided with a connecting rectangular groove c1, and the temperature detection device b44 The side of the inner wall of b44 is fixedly connected with an elastic sealing band c2, and the end of the elastic sealing band c2 away from the temperature detection device b44 is fixedly connected with a top plate c3, and one end of the inner wall connecting the rectangular groove c1 is fixedly connected with a spring c4, the spring The end of c4 away from the connecting rectangular slot c1 is fixedly connected with an arc-shaped limiting plate c5, and the side of the arc-shaped limiting plate c5 close to the spring c4 is fixedly connected with a temperature detector c6; The air makes the elastic sealing belt c2 deform and drives the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com