Method and system for processing equipment fault information of battery swap station

A technology of fault information and processing methods, applied in the field of information communication, can solve problems such as difficulty in unified and timely discovery and processing of fault information, and difficulty in unified management, and achieve the effects of avoiding repeated notifications and saving system resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

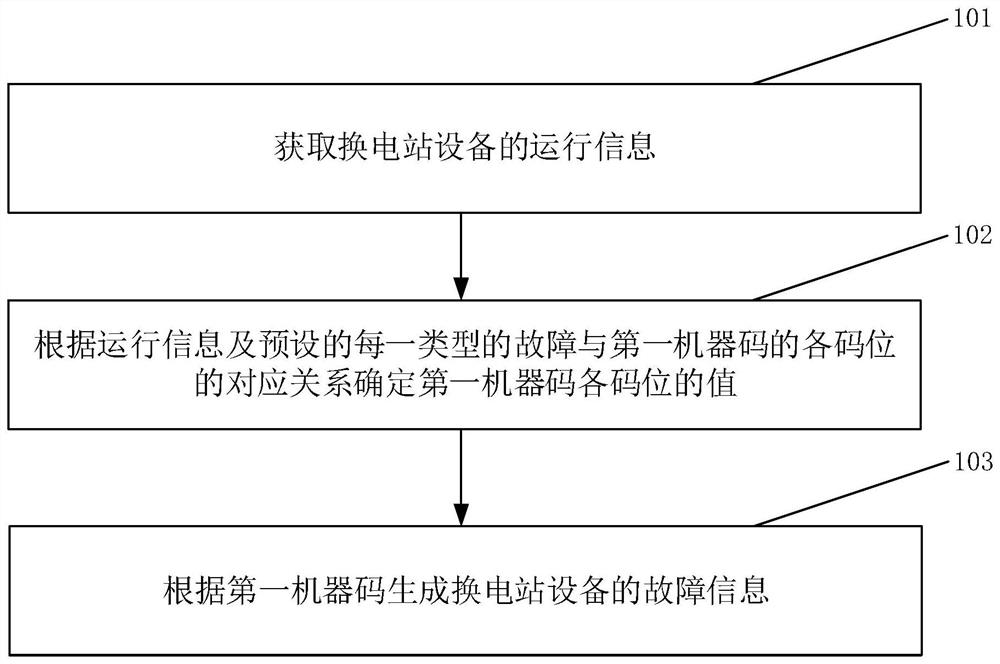

[0074] This embodiment provides a method for processing fault information of substation equipment, such as figure 1 As shown, the processing method includes:

[0075] Step 101 , acquiring operation information of the power station equipment.

[0076] Step 102: Determine the value of each code bit of the first machine code according to the operation information and the preset correspondence between each type of fault and each code bit of the first machine code.

[0077] Step 103: Generate fault information of the power station equipment according to the first machine code.

[0078] Wherein, each first machine code corresponds to one power swapping device, and each first machine code includes all fault information of the corresponding power swapping device. The corresponding relationship of each code position of the first machine code can be set according to actual needs, for example, the first code position indicates that the voltage is too high, the second code position indi...

Embodiment 2

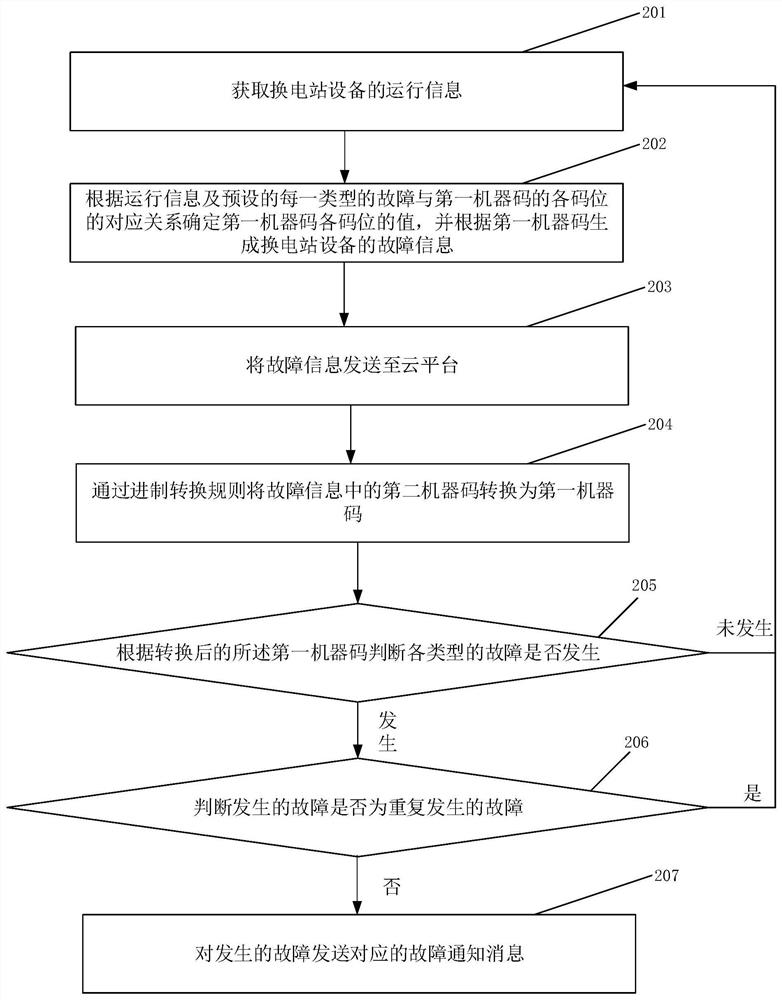

[0085] This embodiment provides a method for processing fault information of substation equipment, such as figure 2 As shown, the processing method includes:

[0086] Step 201, acquire the operation information of the power station equipment.

[0087] Step 202: Determine the value of each code bit of the first machine code according to the corresponding relationship between the operating information and the preset faults of each type and each code bit of the first machine code, and generate the fault of the power station equipment according to the first machine code information.

[0088] Step 203, sending the fault information to the cloud platform.

[0089] Step 204: Convert the second machine code in the fault information into the first machine code through the base conversion rule.

[0090] Step 205 , judging whether various types of faults occur according to the converted first machine code, if so, execute step 206 , if not, execute step 201 .

[0091] Step 206 , judg...

Embodiment 3

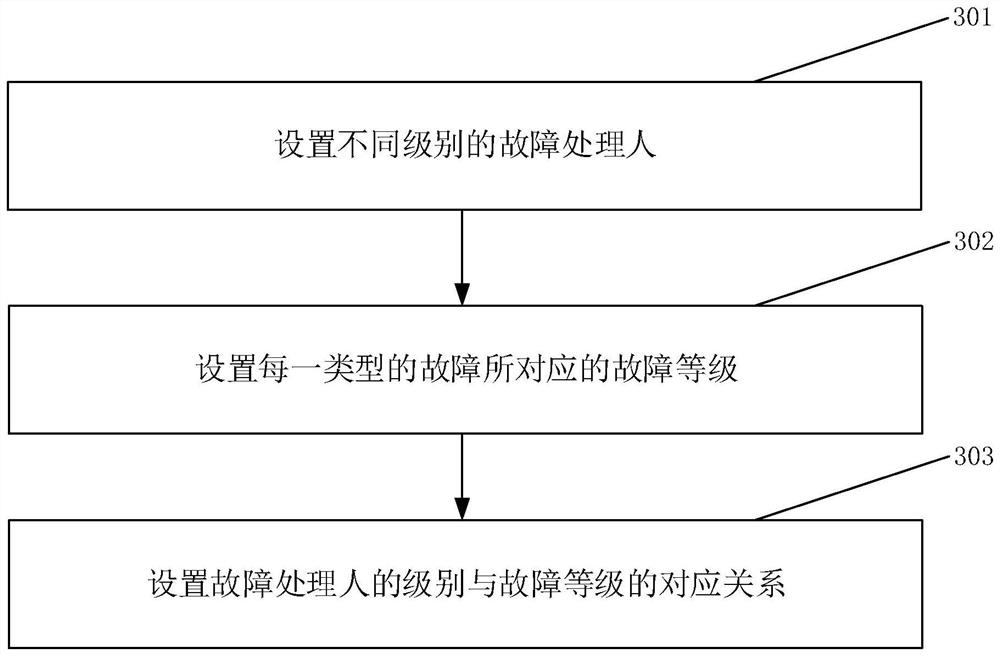

[0112] This implementation is a further improvement on Example 2, such as image 3 and Figure 4 As shown, the processing method of the equipment failure information of the power station in this embodiment also includes:

[0113] Step 301, setting fault handlers of different levels.

[0114] Step 302, setting the fault level corresponding to each type of fault.

[0115] Step 303, setting the corresponding relationship between the level of the fault handler and the fault level.

[0116] In this embodiment, step 207 in embodiment 2 is replaced with step 401, and a corresponding fault notification message is sent to a fault handler at a corresponding level for the fault that occurs, and step 402 is executed.

[0117] Step 402 , judging whether the fault occurred after the first time threshold has elapsed. If not, execute step 403 , and if cancel, execute step 201 .

[0118] Step 403 , sending a fault notification message to the fault handler at the upper level.

[0119] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com