Optimization design method for heavy-load and unbalance-load gear transmission system based on motion stability

A motion stability and optimization design technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of gear transmission system vibration, reduce the service life of gear transmission system, noise, etc., to improve work performance, Modeling considers all factors and optimizes the effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the implementation of the present invention is not limited thereto.

[0053] The present invention proposes an optimal design method for heavy-duty and partial-load gear transmission systems based on motion stability, and realizes the optimization of gears by establishing a nonlinear dynamic model of the gear transmission system and combining nonlinear dynamic theory knowledge design.

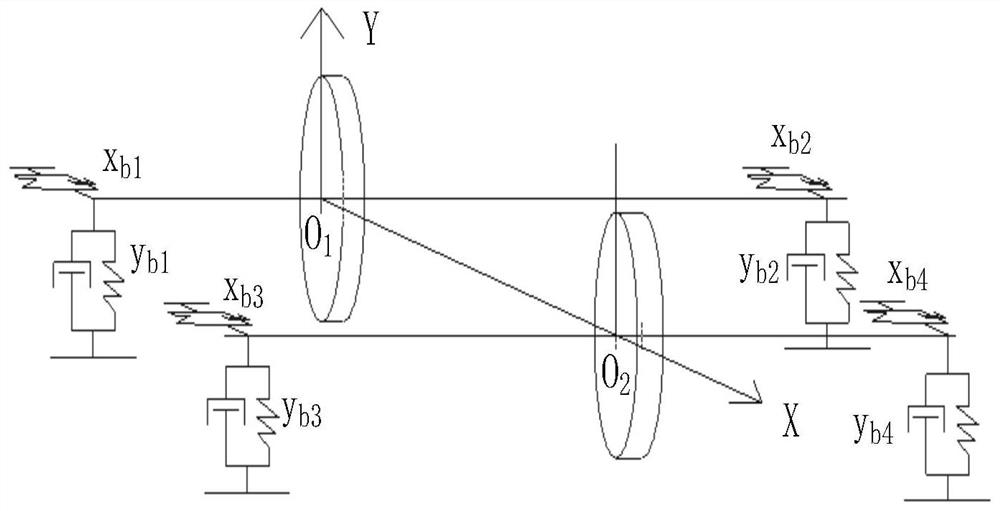

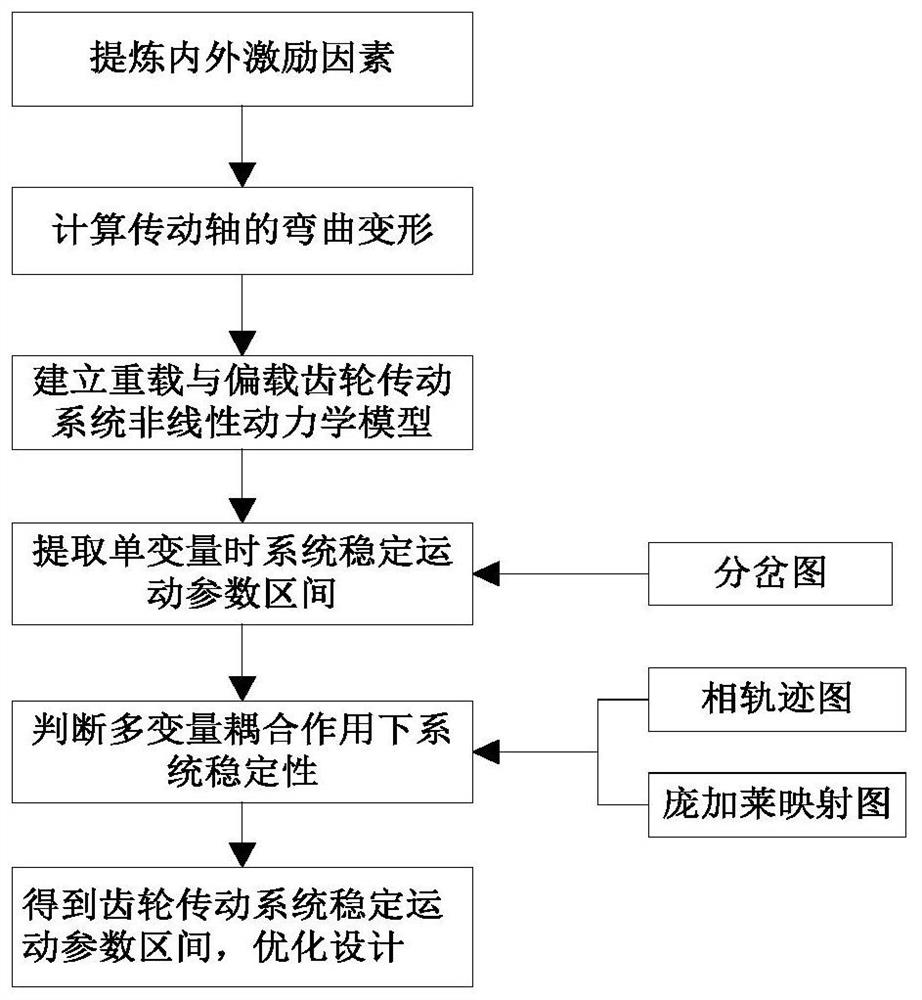

[0054] Including nonlinear dynamic modeling and dynamic characteristic analysis of gear transmission system. In order to clearly and concisely illustrate the method proposed by the present invention, in figure 1 The concrete gear train model is replaced by a simplified model in . The method design flow chart is as follows figure 2 As shown, the specific steps are as follows:

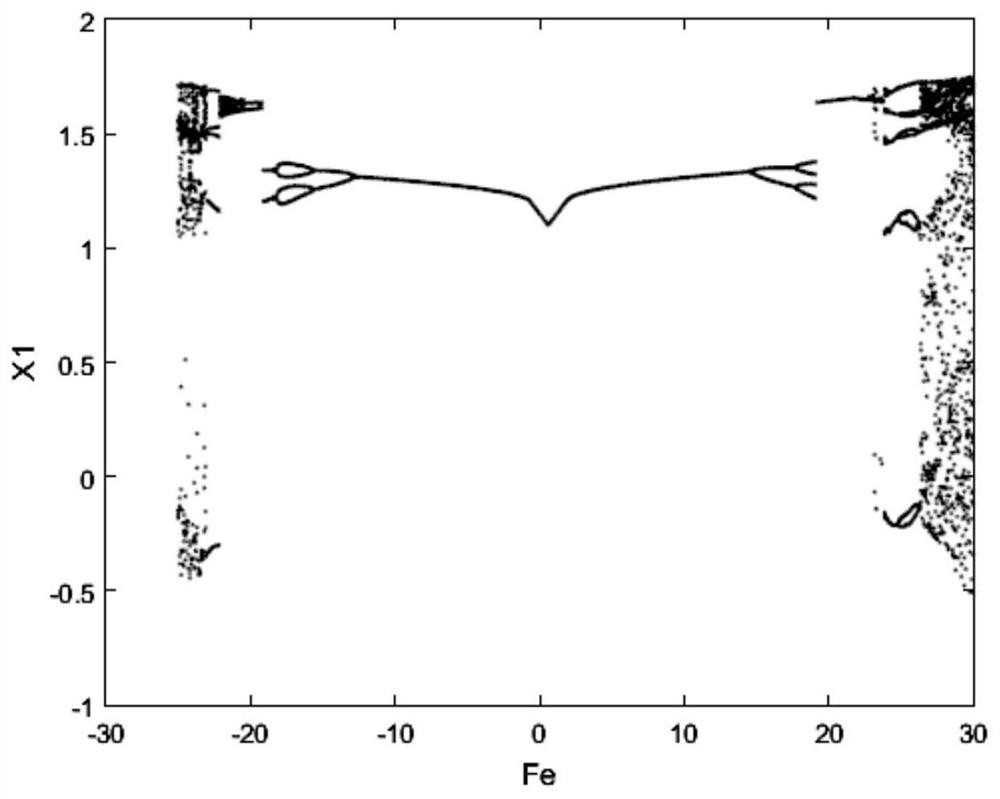

[0055] Step 1: Extract various internal and external motivating factors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com