Supplier quality evaluation early warning method, device and electronic equipment

A quality evaluation and supplier technology, applied in business, data processing applications, instruments, etc., can solve the problems of abnormal data integration and analysis, high analysis cost, difficult analysis, etc., and achieve the effect of reasonable evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

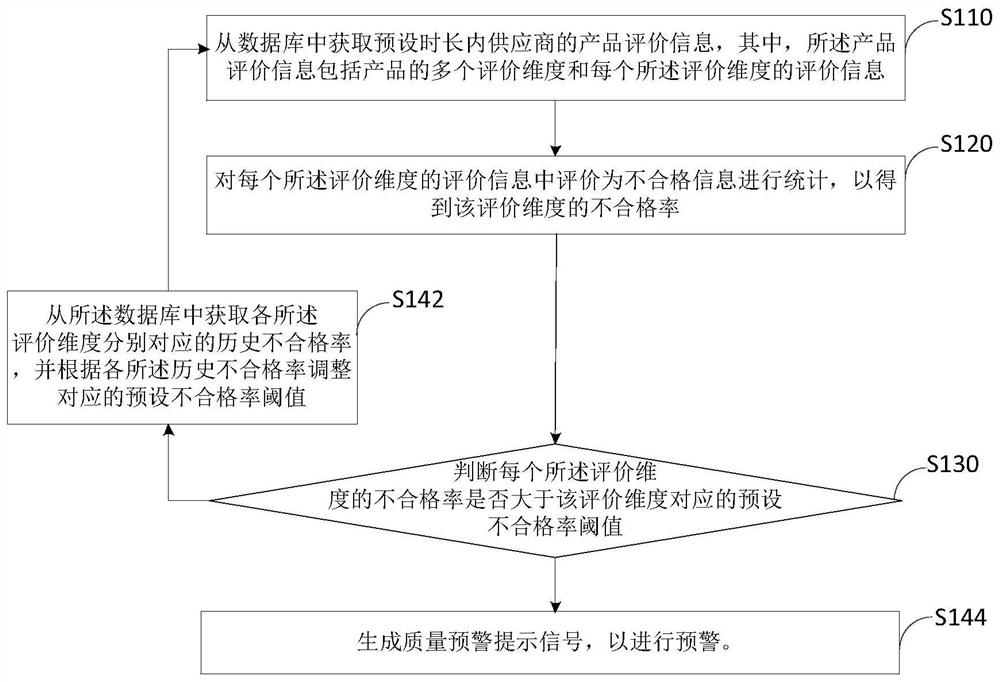

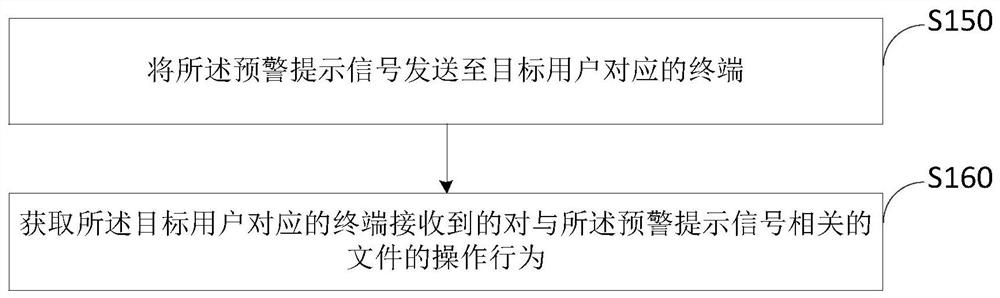

[0048] see figure 1, the present application provides a supplier quality evaluation early warning method that can be applied to electronic equipment, and when the method is applied to electronic equipment, step S110-step S144 is performed.

[0049] Step S110: Obtain product evaluation information of the supplier within a preset time period from the database, wherein the product evaluation information includes evaluation information of multiple evaluation dimensions of the product.

[0050] Step S120: Perform statistics on the unqualified information in the evaluation information of each evaluation dimension to obtain the unqualified rate of the evaluation dimension.

[0051] Step S130: Determine whether the unqualified rate of each evaluation dimension is greater than the preset unqualified rate threshold corresponding to the evaluation dimension.

[0052] When the unqualified rate of each evaluation dimension is not greater than the corresponding preset unqualified rate thre...

Embodiment 2

[0088] The embodiment of the present application also provides a supplier quality evaluation early warning device, the supplier quality evaluation early warning device includes a processor, wherein the processor is used to execute the following program modules stored in the memory:

[0089] The obtaining module is used to obtain the product evaluation information of the supplier within a preset period of time from the database, wherein the product evaluation information includes evaluation information of multiple evaluation dimensions of the product.

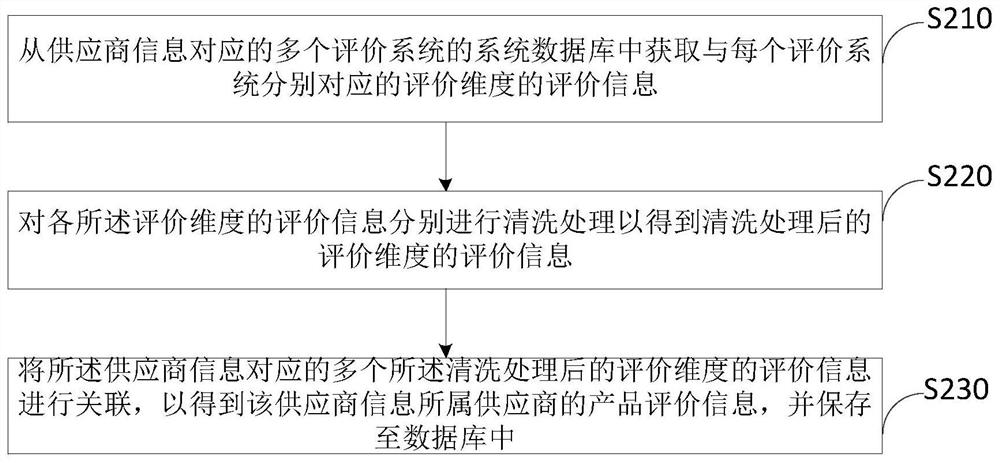

[0090] Due to fetching modules and figure 1 The implementation principle of step S110 is similar, so no further description is given here. It should be noted that, in this embodiment, the product data in the database can be obtained according to steps S210-S230, which will not be described in detail here.

[0091] The statistics module is used to make statistics on the unqualified information in the evaluation information of ea...

Embodiment 3

[0103] This embodiment also provides a computer-readable storage medium, such as flash memory, hard disk, multimedia card, card-type memory (for example, SD or DX memory, etc.), random access memory (RAM), static random access memory (SRAM), only Read memory (ROM), electrically erasable programmable read-only memory (EEPROM), programmable read-only memory (PROM), magnetic memory, magnetic disk, optical disk, server, App application store, etc., on which computer programs are stored, When the computer program is executed by the processor, the method steps in the first embodiment above can be implemented.

[0104] For the specific implementation process of the steps of the above method, refer to Embodiment 1, and this embodiment will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com