Gas-solid cross-flow reaction chamber of adsorption tower

A technology of reaction chamber and adsorption tower, which is applied in the field of gas-solid cross-flow reaction chamber of adsorption tower, can solve the problems of not explaining the design principles of grid structure, solid particles being blown out by flue gas, and the inability to accurately adjust the downward flow rate of solid materials, etc. , to achieve the effect of enhancing the gas-solid separation effect, increasing the gas-solid contact area, and avoiding overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

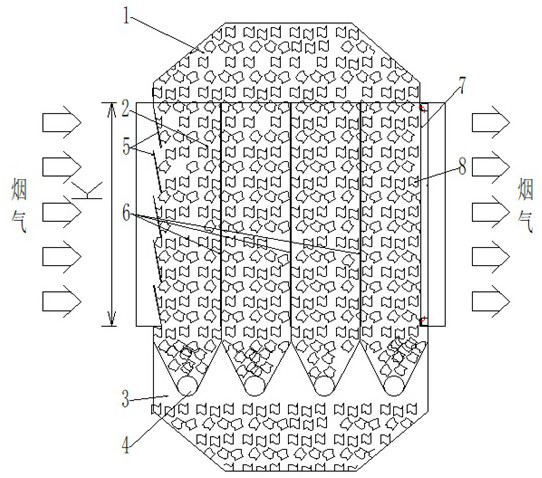

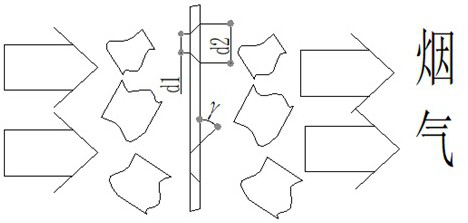

[0030] Such as figure 1 In the gas-solid cross-flow reaction chamber shown in this embodiment, the upper end of the gas-solid cross-flow reaction chamber 2 is connected to the feed bin 1, and the lower end is connected to the discharge bin 3; The arranged partition wall 6 is divided into four sub-bins, and an unloader 4 is installed at the lower end of each sub-bin; the solid material 8 enters from the feed bin 1, passes through the gas-solid cross-flow reaction chamber 2 downward along a certain sub-bin, After coming out from the unloader 4, it enters the discharge bin 3. The flue gas enters the reaction chamber 2 from the wall 5 of the inlet grid plate, starts to contact and react with the solid material 8, flows through the partition walls 6 of each chamber, and finally flows out of the reaction chamber through the gas-solid separation wall 7.

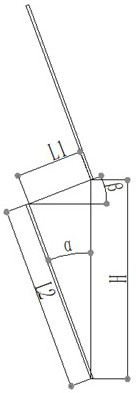

[0031] In this embodiment, the inlet grid plate wall 5 is composed of n inclined grid plates arranged vertically on the windward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com