Sponge deodorizing and drying device

A drying device and sponge technology, applied in the direction of drying gas arrangement, drying solid materials, drying solid materials without heating, etc., can solve the problem of inability to remove harmful substances, achieve shortened deodorization cycle, convenient operation, and efficient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

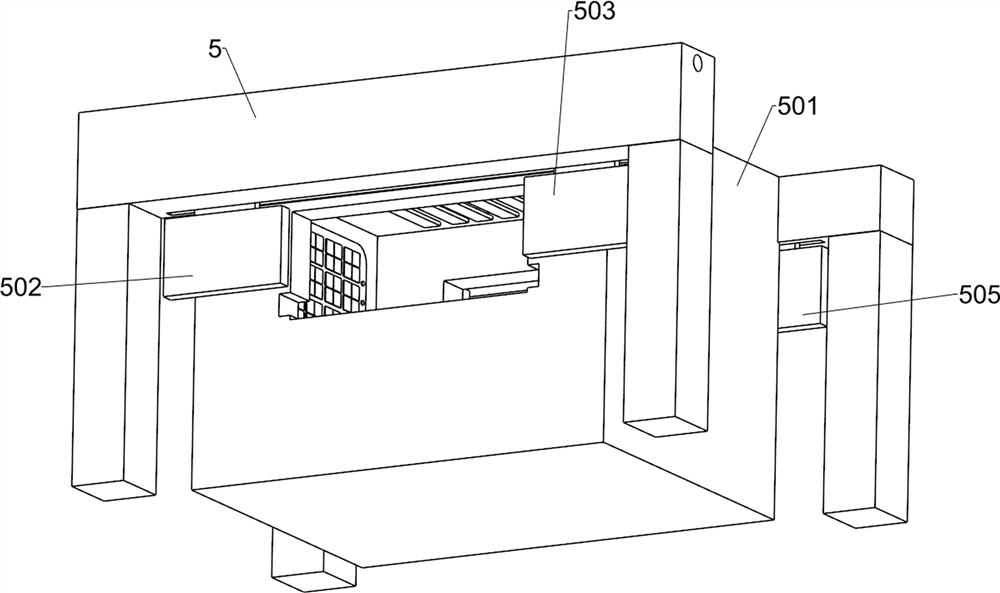

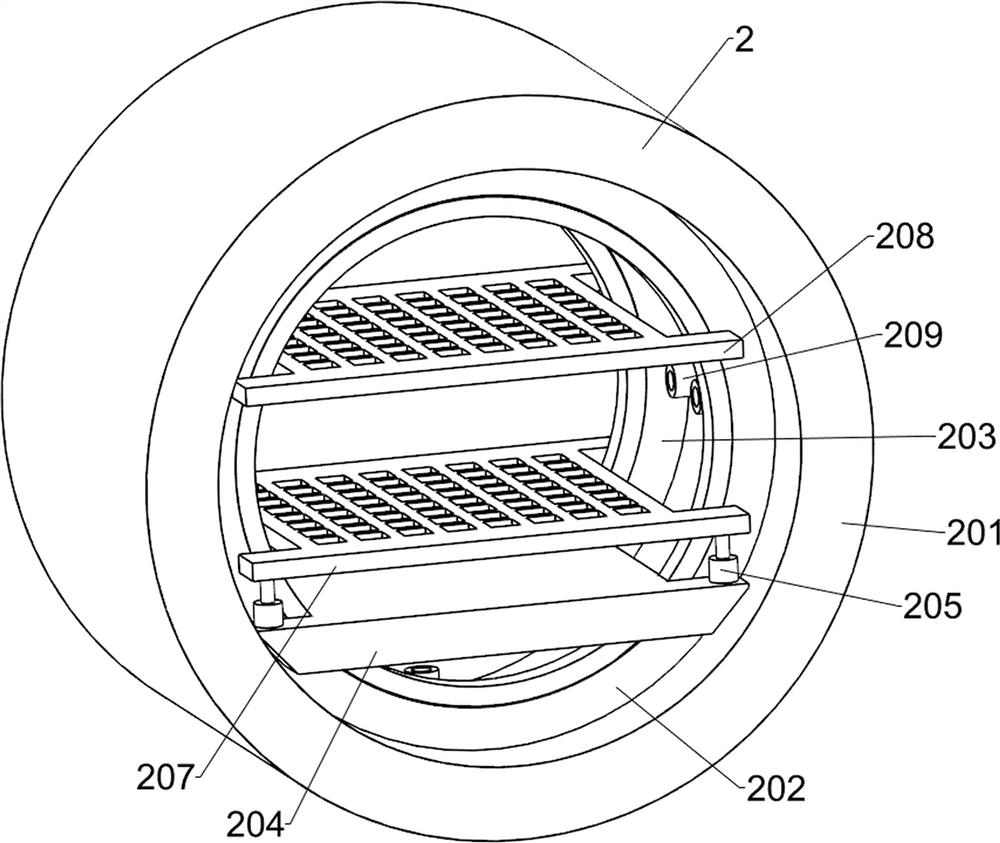

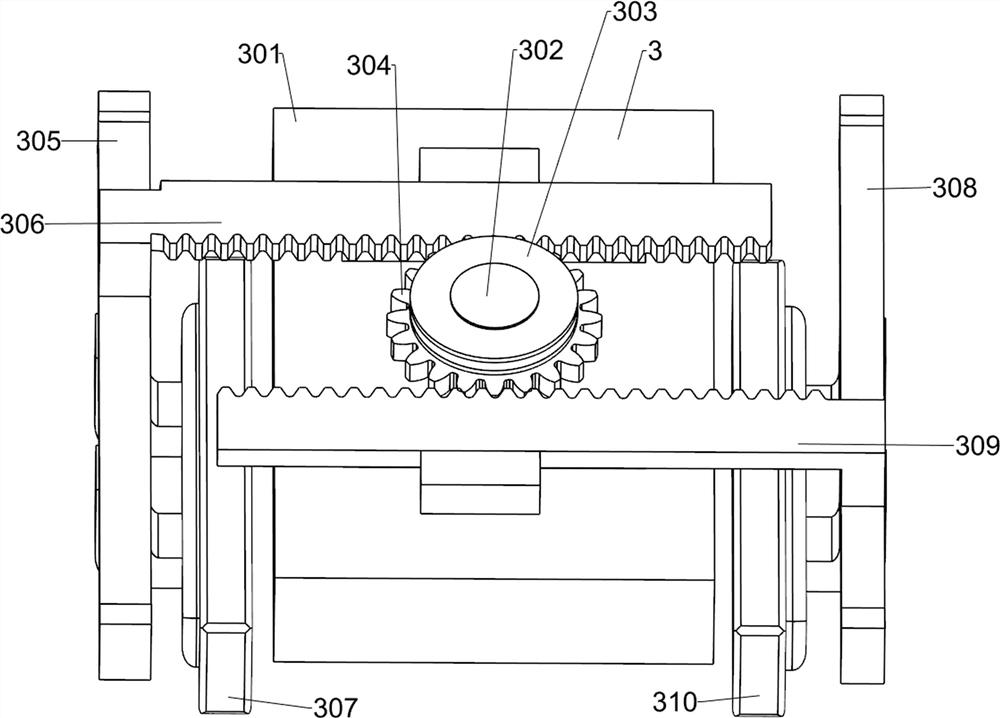

[0037] A sponge deodorization drying device, such as Figure 1-15 As shown, it includes a conveying component, deodorizing component, cleaning component, spin-drying component, drying component, power component, support platform, console, first drainage box and second drainage box; the conveying component is connected with the drying component The conveying component is connected with the power component; the conveying component is connected with the support platform; the conveying component is connected with the first drainage tank; the conveying component is connected with the second drainage tank; Connected with the power component; connected with the cleaning component and the support platform; connected with the drying component and the drying component; connected with the power component; connected with the support platform; connected with the second drainage box ; The drying assembly is connected with the console; the drying assembly is connected with the second drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com