A high-precision full-contact surface chuck

A contact surface, high-precision and complete technology, applied in the direction of expanding the mandrel, etc., can solve the problems of reducing production efficiency, workpiece turning, and reducing cutting accuracy, and achieve the effects of improving processing efficiency, fast clamping, and improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

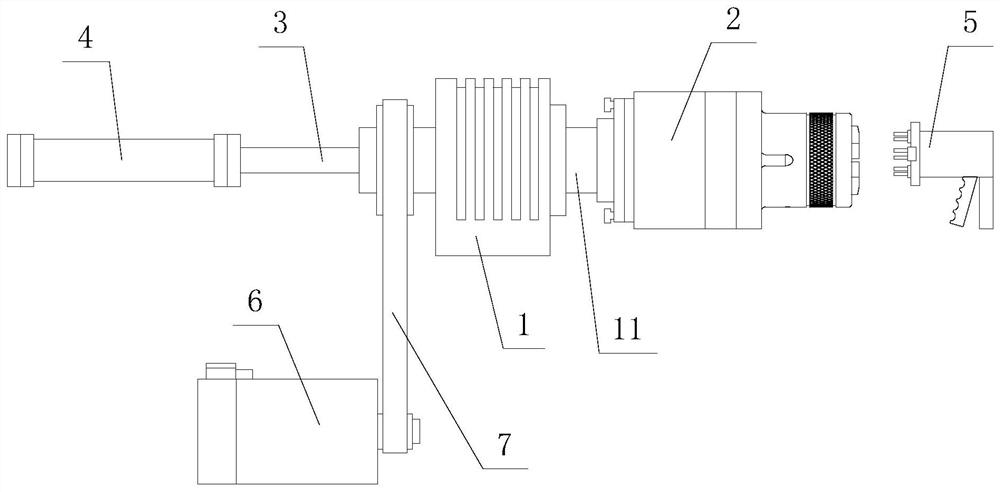

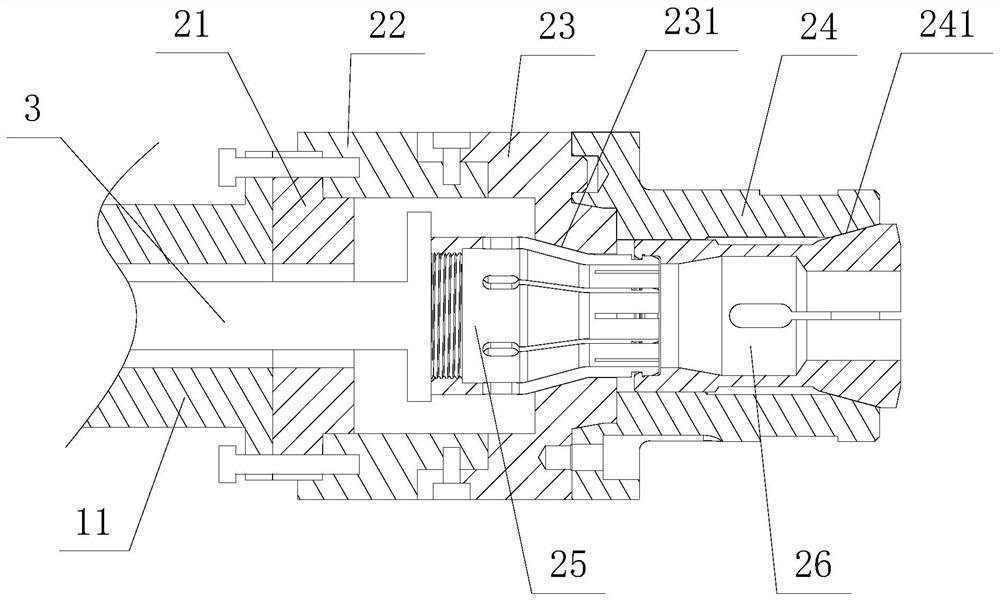

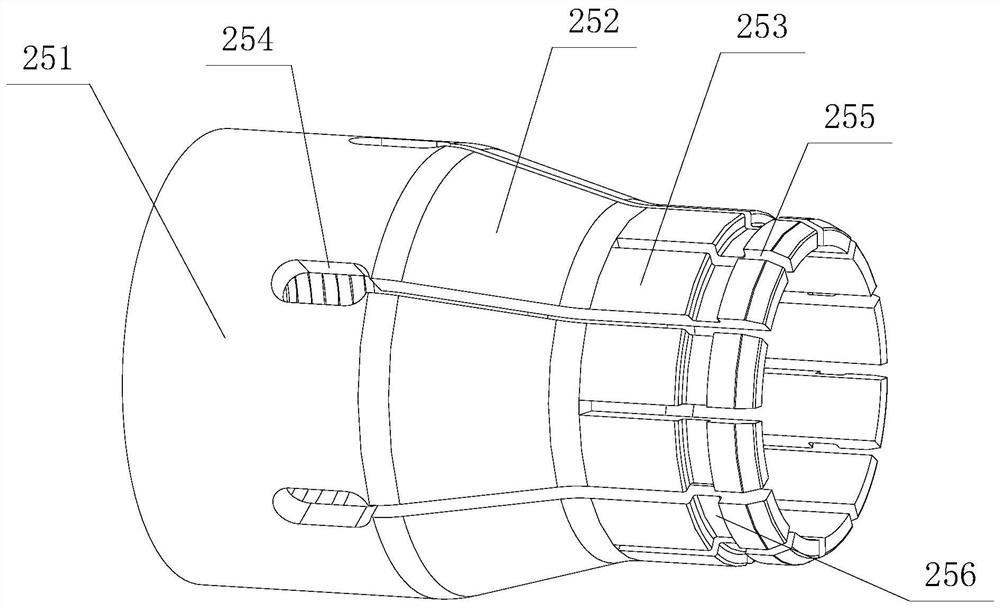

[0026] Such as Figure 1 to Figure 5As shown, the high-precision full-contact surface chuck provided in this embodiment includes a headstock 1, a chuck assembly 2, a pull stud 3 and a hydraulic device 4, and a motor 6 is provided on one side of the headstock 1, and the output shaft of the motor 6 passes through a belt 7 is connected with the input shaft of the headstock 1 to provide power for the headstock 1. The headstock 1 is provided with a hollow main shaft 11, and one end of the main shaft 11 is connected with a chuck assembly 2, and the chuck assembly 2 includes a connection Disc 21, tail disc 22, middle disc 23, outer disc 24, extension spring 25 and collet 26, the connecting disc 21 is fixedly connected with the main shaft 11, and the connecting disc 21, tail disc 22, middle disc 23 and outer disc 24 They are all ring-shaped and connected in sequence, and a hollow channel is formed in the middle for installing a tension spring 25 and a collet 26. The tension spring 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com