Chassis control method and chassis control system

A control method and technology for a control system, applied in the field of chassis control methods and chassis control systems, can solve problems such as product development difficulties, and achieve the effects of being beneficial to product development, having multiple levels and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

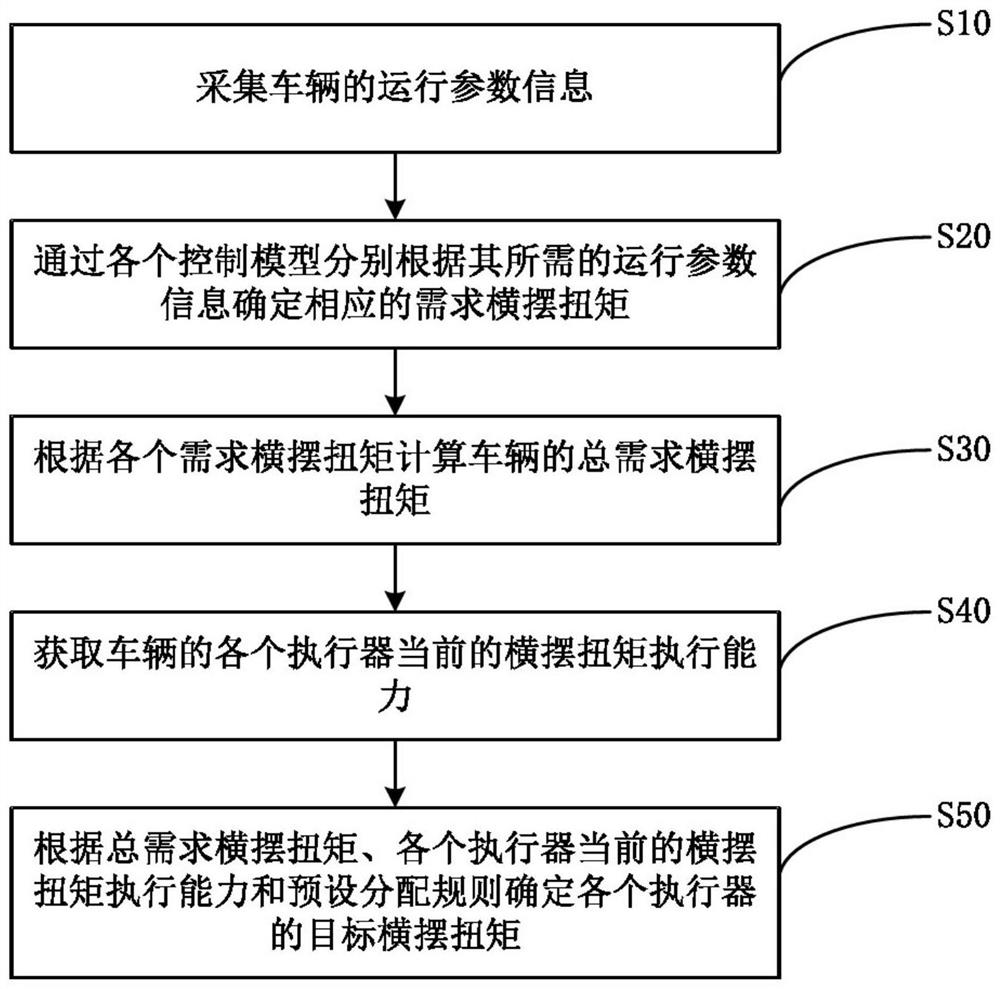

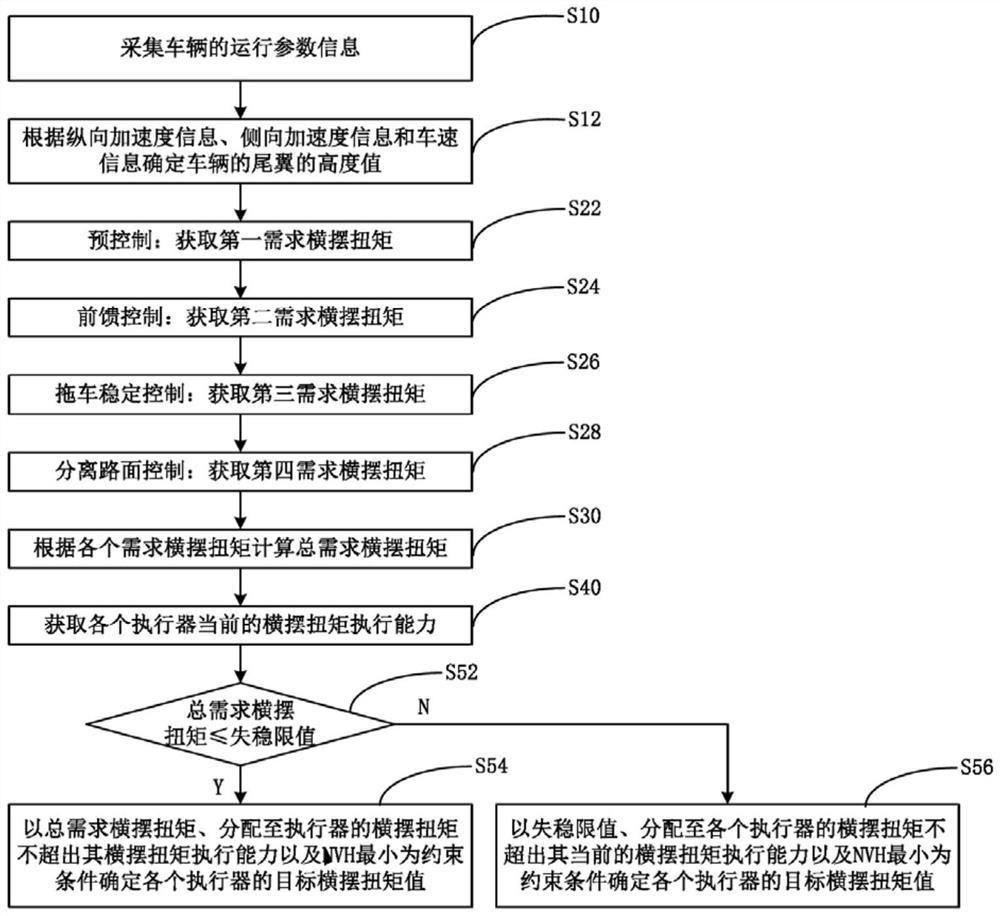

[0048] figure 1 is a flowchart of a chassis control method according to an embodiment of the present invention. In one embodiment, such as figure 1 As shown, the chassis control method includes:

[0049] Step S10, collecting information about operating parameters of the vehicle. The collection process can be to obtain the information collected by the sensor, or to obtain relevant information from the CAN bus of the vehicle, for example, the driving mode information of the vehicle can be obtained from the CAN bus.

[0050] In step S20, each control model is used to determine the corresponding required yaw torque according to the required operating parameter information, and each control model corresponds to each preset operating condition.

[0051]Step S30, calculating the total required yaw torque of the vehicle according to each required yaw torque.

[0052] Step S40, acquiring the current yaw torque execution capability of each actuator of the vehicle.

[0053] In step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com