Glass composition

A glass composition, P2O5 technology, applied in the field of glass composition, can solve the problems of cracking, reducing the glass yield, reducing the service life of the glass, etc., and achieving the effects of low thermal expansion coefficient and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133]

[0134] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

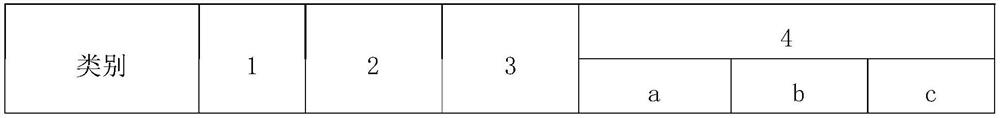

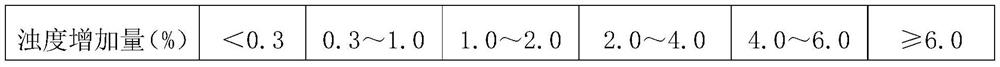

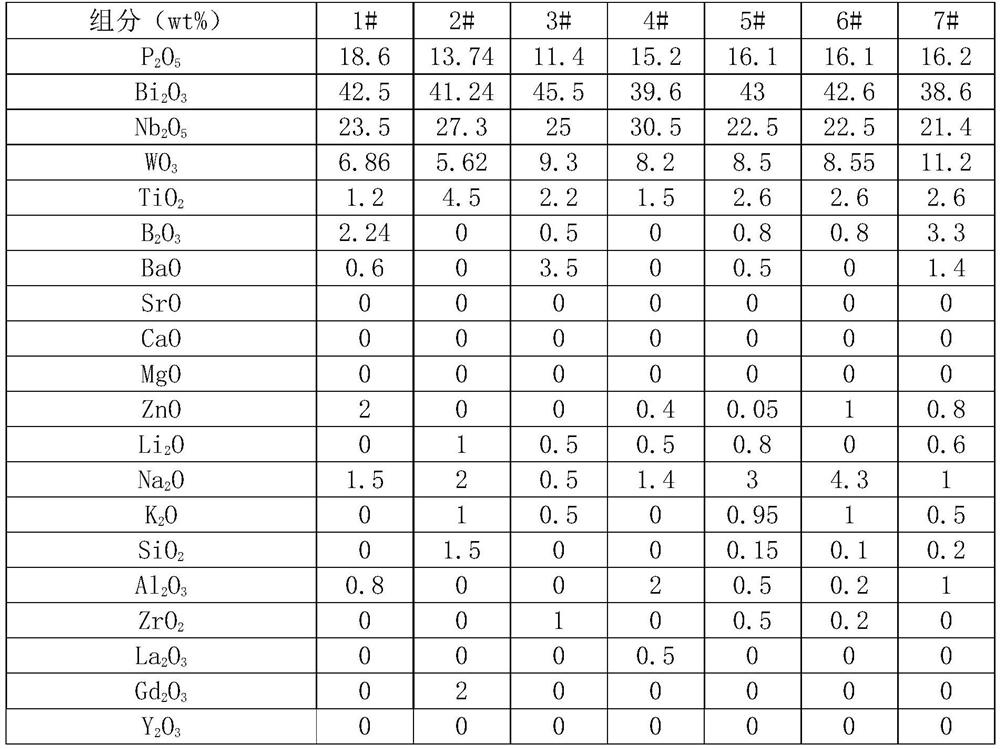

[0135] In this example, glass compositions having the compositions shown in Tables 2 to 4 were obtained by using the above-mentioned manufacturing method of the glass composition. In addition, the characteristics of each glass are measured by the test method described in the present invention, and the measurement results are shown in Tables 2 to 4, where P 2 o 5 , Nb 2 o 5 、WO 3 、TiO 2 , B 2 o 3 、Al 2 o 3 , RO and Rn 2 The total content of O is represented by A, P 2 o 5 、 Bi 2 o 3 , Nb 2 o 5 、WO 3 、TiO 2 and Rn 2 The total content of O is represented by B.

[0136] Table 2.

[0137]

[0138]

[0139] table 3.

[0140]

[0141]

[0142]

[0143] Table 4.

[0144]

[0145]

[0146]

[0147] The glass obtained in Examples 1 to 20 of the glass composition is used, fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap