Cleaning and maintaining equipment for subway rail transit

A technology for rail transit and maintenance equipment, which is applied in track cleaning, track maintenance, track, etc., and can solve the problems of unable to level rail stones, unable to remove debris, and inconvenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

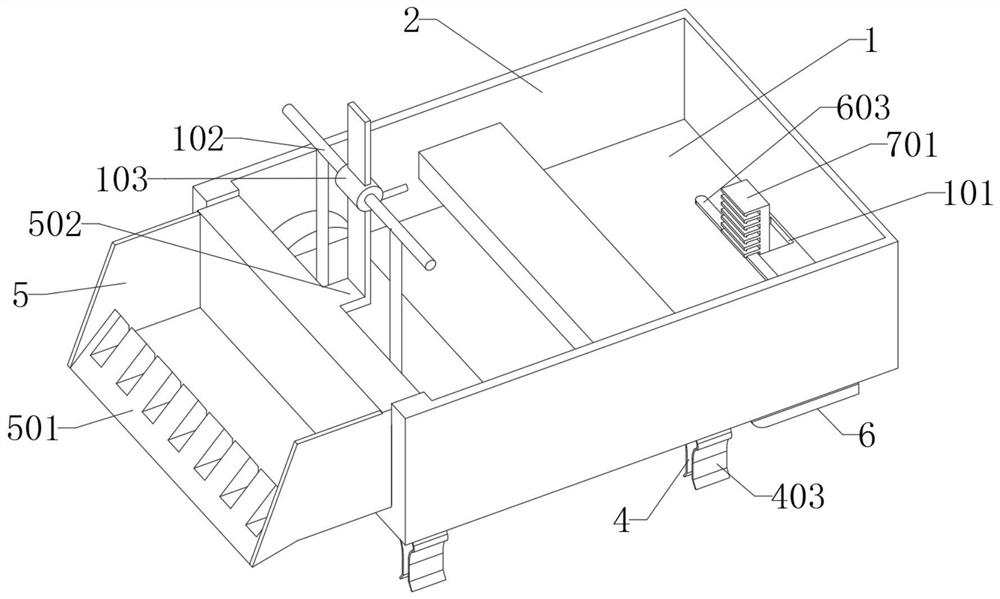

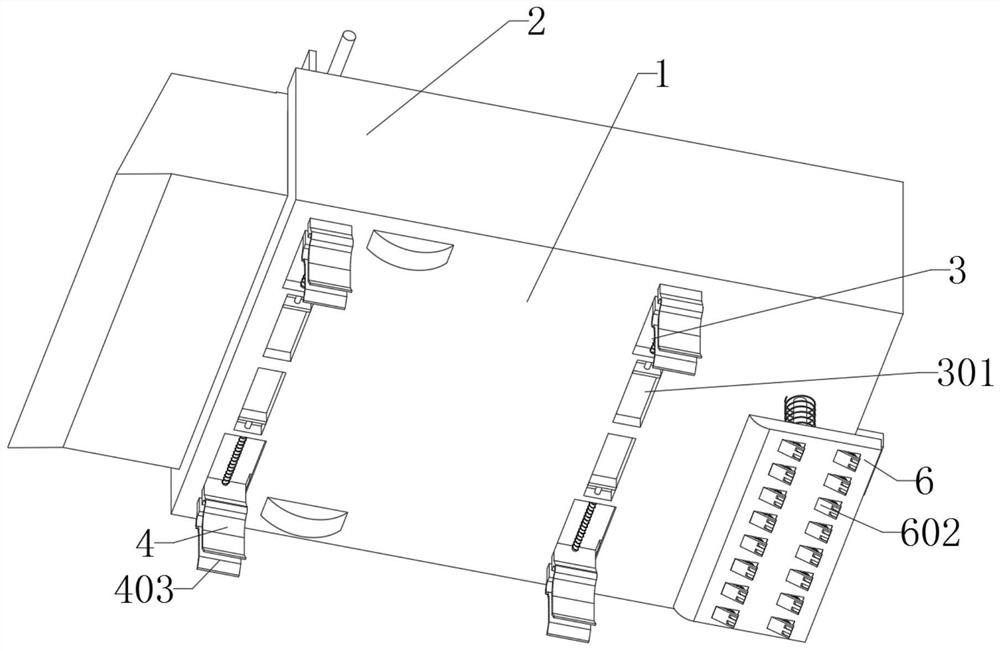

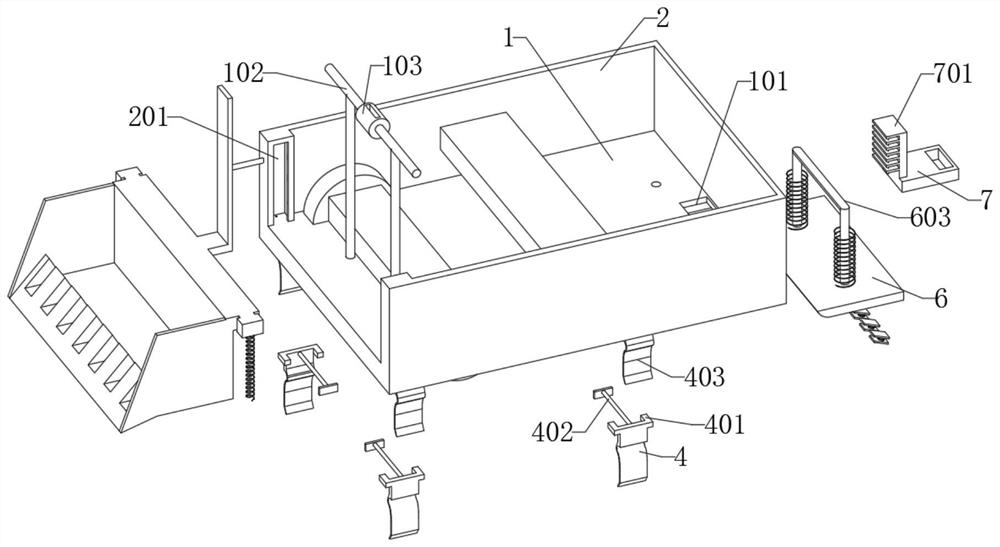

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a cleaning and maintenance equipment for subway rail transit, comprising a main body 1, an enclosure 2, a bottom groove 3, a moving plate 4, a collecting part 5, a rectifying plate 6 and a pulling part 7; the main body 1 has a rectangular structure, and The top of the main body 1 is equipped with a driving motor, and the two sides of the driving motor are connected with moving wheels; the enclosure 2 is fixedly installed on the top edge of the main body 1, and the inside of the enclosure 2 is provided with a horizontal plate; the bottom groove 3 Located at the bottom corner of the main body 1; the collection piece 5 is installed on the left side of the main body 1, and the T-shaped block of the collection piece 5 is inserted into the guide groove 201, and the insert plate 502 of the collection piece 5 is inserted into the guide The inside of the rectangular groove of the part 103; the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com