Integrated damping switch separate layer fracturing device and method

A layered fracturing and damping technology, which is used in wellbore/well valve devices, production fluids, and earth-moving drilling, etc., and can solve the risks of inability to achieve full well section backwashing, difficult layered fracturing, and pipe sticking. and other problems, to achieve the effect of improving anti-blocking ability, reducing erosion, and improving layered construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

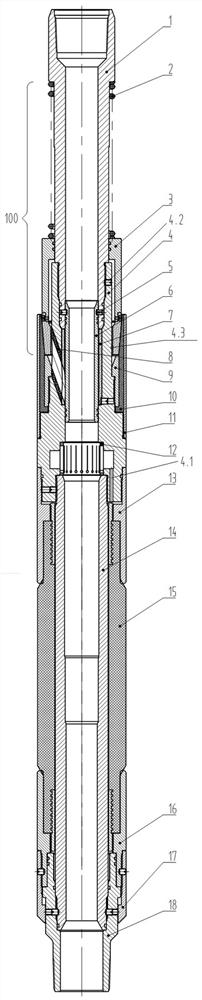

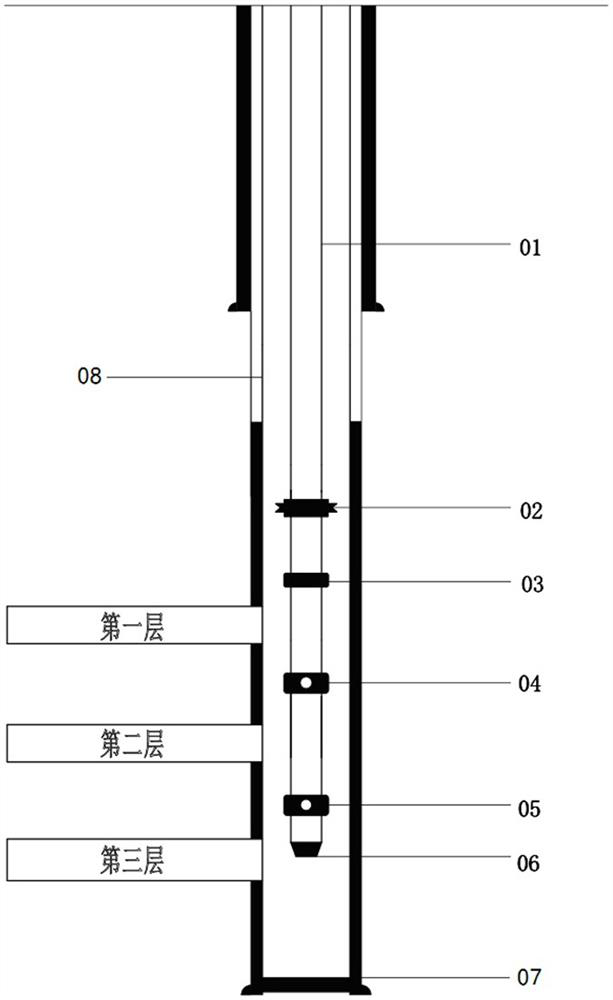

[0033] Embodiment 1, with reference to figure 1, an integrated damping switch layered fracturing device mentioned in the present invention, including an upper joint 1, a closing spring 2, a closing sleeve 3, an intermediate joint 4, a shear pin 5, a fracturing sliding sleeve 6, and an inner protection ring 7 , diversion tube 8, fixed ring 9, outer protective ring 10, diversion sleeve 11, slotted sleeve 12, upper rubber sleeve seat 13, center pipe 14, rubber sleeve 15, lower rubber sleeve base 16, downwell protection sleeve 17, The lower joint 18, the closing spring 2 and the closing sleeve 3 are movably fitted on the upper joint 1 sequentially from top to bottom, the lower part of the upper joint 1 is fixedly connected with the upper part of the middle joint 4, and the interior of the upper joint 1 is connected with the fracturing pin 5 through the shear pin 5. The sliding sleeve 6 is fixedly connected. There are more than two hole-type fracturing channels in the middle of the...

Embodiment 2

[0051] Embodiment 2, with reference to figure 1 , an integrated damping switch layered fracturing device mentioned in the present invention, including an upper joint 1, a closing spring 2, a closing sleeve 3, an intermediate joint 4, a shear pin 5, a fracturing sliding sleeve 6, and an inner protection ring 7 , diversion tube 8, fixed ring 9, outer protective ring 10, diversion sleeve 11, slotted sleeve 12, upper rubber sleeve seat 13, center pipe 14, rubber sleeve 15, lower rubber sleeve base 16, downwell protection sleeve 17, The lower joint 18, the closing spring 2 and the closing sleeve 3 are movably fitted on the upper joint 1 sequentially from top to bottom, the lower part of the upper joint 1 is fixedly connected with the upper part of the middle joint 4, and the interior of the upper joint 1 is connected with the fracturing pin 5 through the shear pin 5. The sliding sleeve 6 is fixedly connected. There are more than two hole-type fracturing channels in the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com