Integrated single-channel heat flow power all-in-one machine

An all-in-one, single-channel technology, used in power units, engine components, machines/engines, etc., to achieve the effects of easy switching, wide application prospects, and optional air outlets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

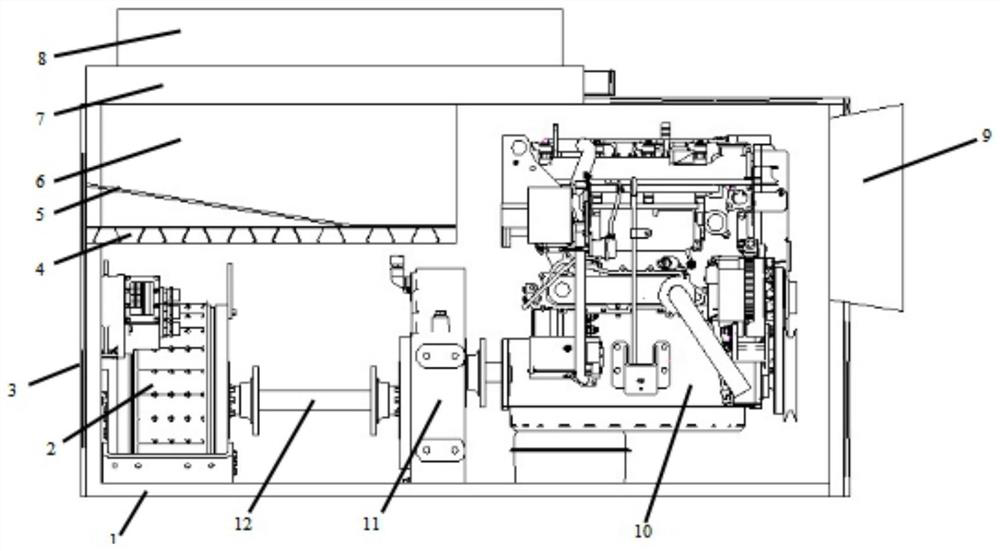

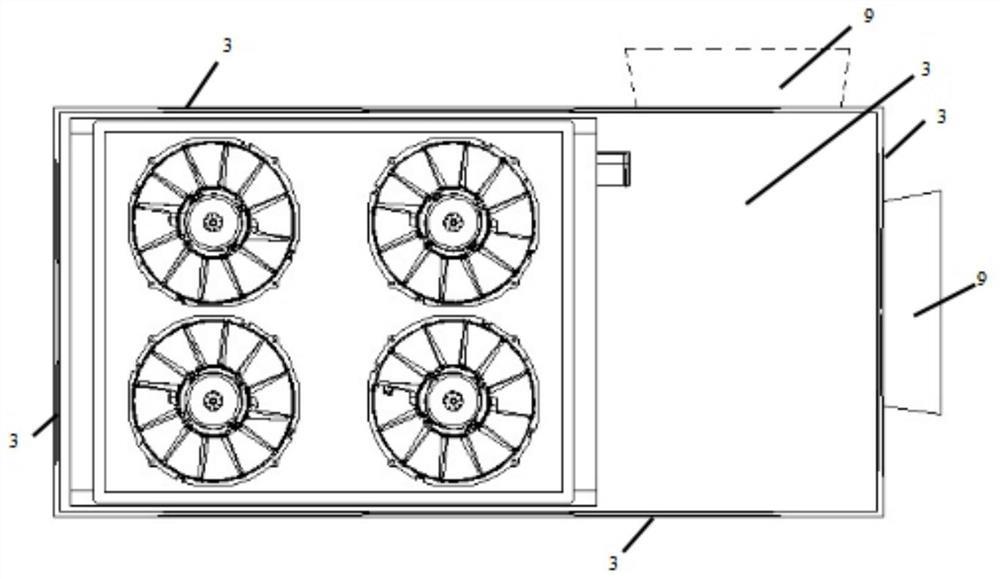

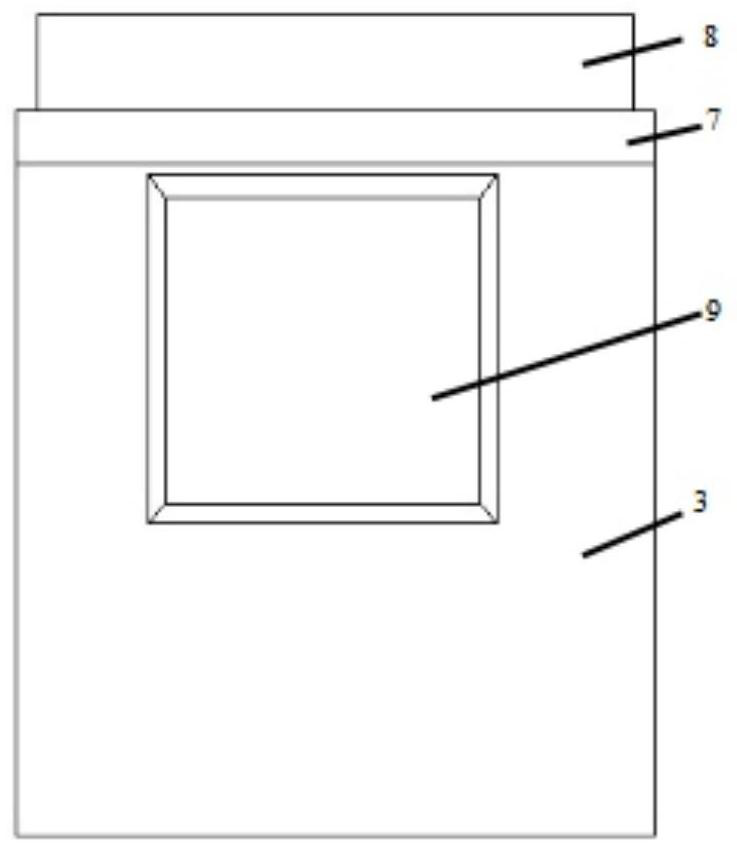

[0019] This embodiment proposes an integrated single-channel heat flow power integrated machine, its structure is as follows Figure 1~3 As shown, it includes an all-in-one machine frame 1, generator 2, heat insulation layer 3, wave-shaped dust collection tank 4, dust collection net 5, air duct 6, radiator 7, cooling fan 8, exhaust connection cover 9, engine 10, Transfer case 11 and connecting shaft 12.

[0020] The main structure of the all-in-one machine is an integrated machine frame 1. The all-in-one machine frame 1 is a square structure and is welded by profiles. The peripheral sealing plate is fixed on the outer surface of the all-in-one machine frame 1 through thin steel plates + fasteners. Detachable structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com