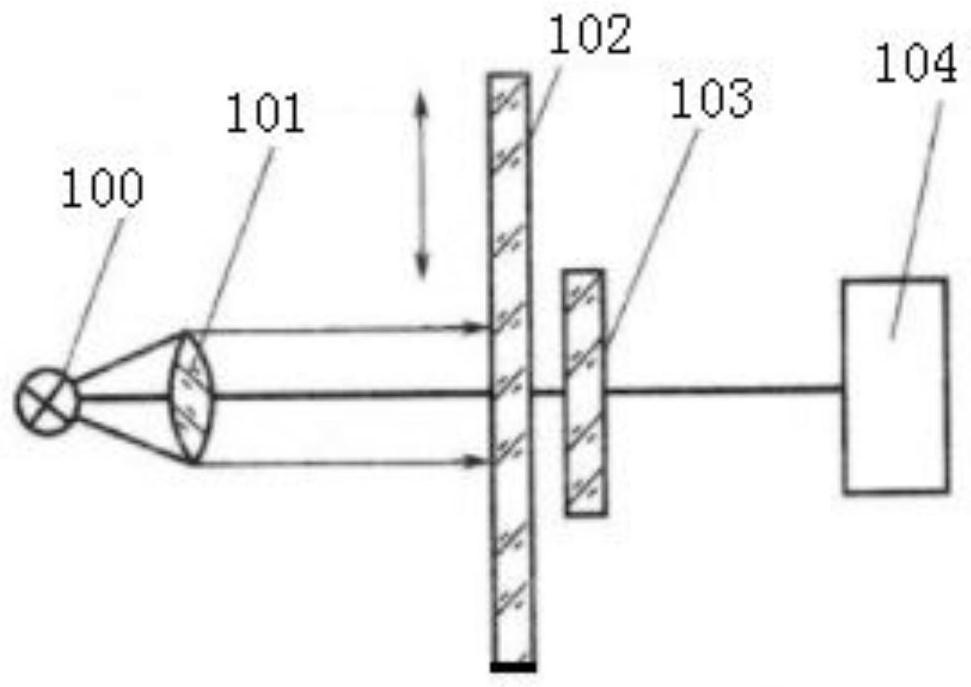

Moire fringe-based detection device and detection method

A Moiré fringe and detection device technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of high operation difficulty, complex assembly process, and difficulty in manufacturing accuracy, and achieves cost reduction, convenient use, Adjustable and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

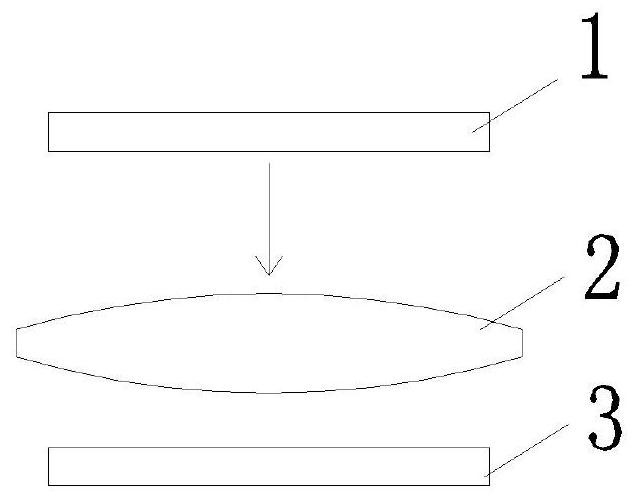

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

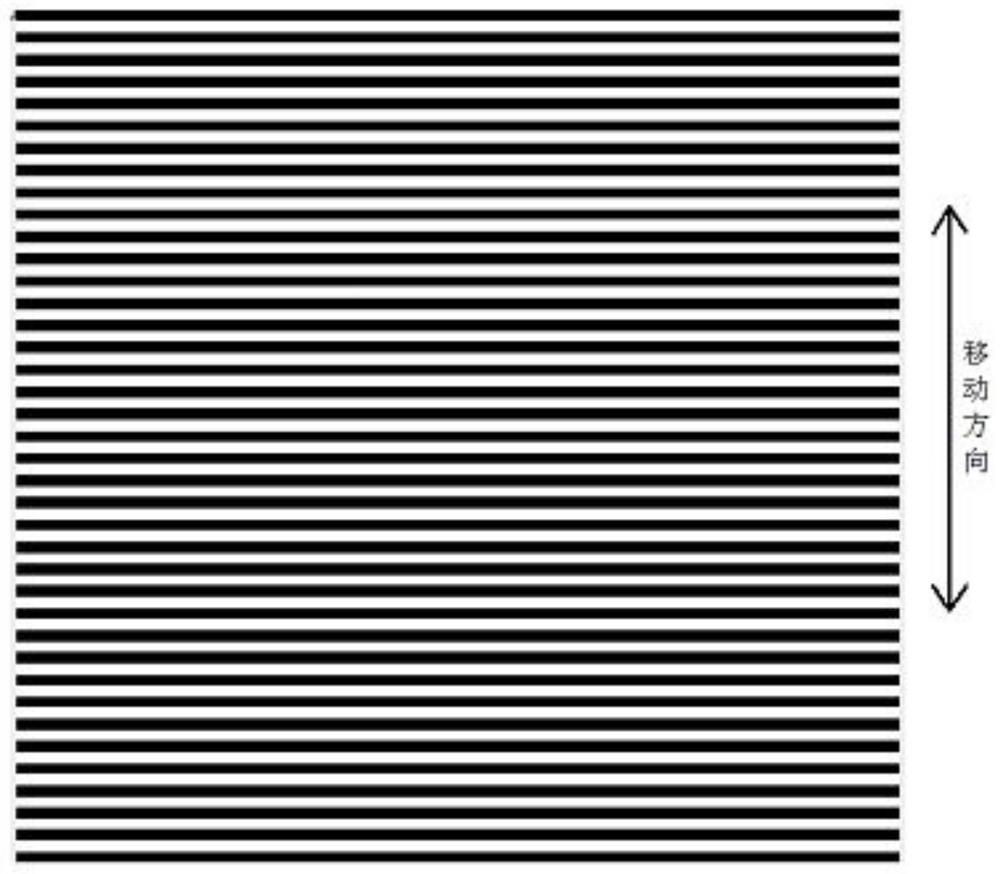

[0033] See figure 2 , a detection device based on Moiré fringes in a specific embodiment, comprising a light source 1 of an area array and a photodetector 3 of an area array, the light source 1 of the area array and the photodetector 3 are arranged in parallel to each other and can be relatively positioned along its own Where the plane is sliding, an imaging lens 2 is arranged in parallel between the light source 1 of the area array and the photodetector 3 , and the light beam emitted by the light source 1 of the area array is imaged on the photodetector 3 after passing through the imaging lens 2 . During implementation, you can choose to set the light source on the sliding carrier, the photodetector and imaging lens are relatively fixed as fixed items, and the vertical distance from the imaging lens to the photodetecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com